The Winchester post-’64 Model 70 is popular with hunters and shooters. Examples include: (1) Standard 30-06, (2) Classic Featherweight 280 Remington, (3) Jack O’Connor tribute rifle, (4) Black Shadow 7mm WSM and (5) Classic Stainless 375 H&H Magnum.

Sixty years ago, after being in production for around 28 years, Winchester redesigned its legendary Model 70 bolt-action rifle that is commonly known as the post-’64 Model 70 or New Model 70. Initially, this was a huge mistake, as the original was rugged, reliable, handsome and highly respected. By comparison, the quality of the new rifle was initially poor and severely criticized by savvy riflemen, but eventually, quality returned and the design has been steadily upgraded and improved. Once again, the Model 70 became a respected rifle, but unfortunately, Winchester’s New Haven Connecticut, plant was closed in 2006, bringing production to a halt. However, the Model 70 was far too good and the demand too high to let it die. In 2008, manufacturing of the Model 70 resumed, but it was now produced in the FN plant (a subsidiary company) located in Columbia, South Carolina. Beginning in 2013, assembly was moved to Portugal, but by 2015, manufacture was also moved to Portugal, where it remains today.

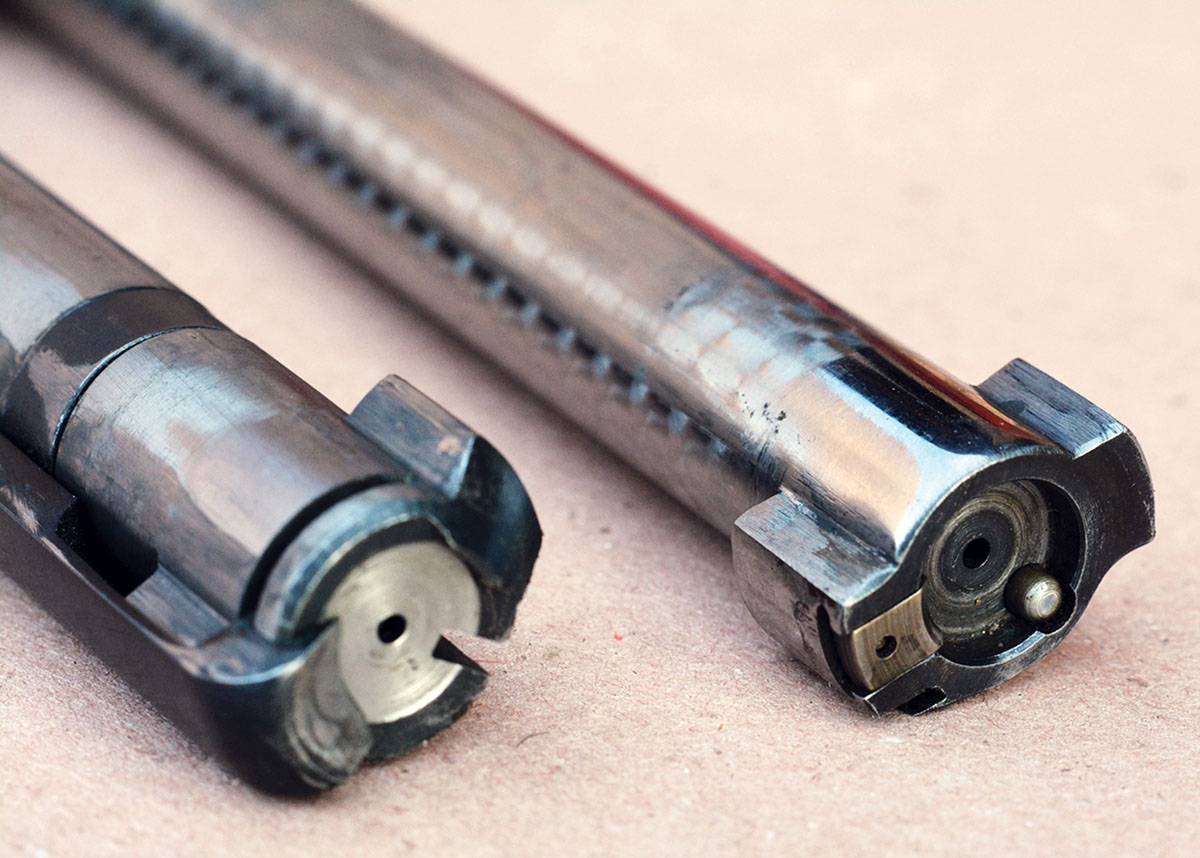

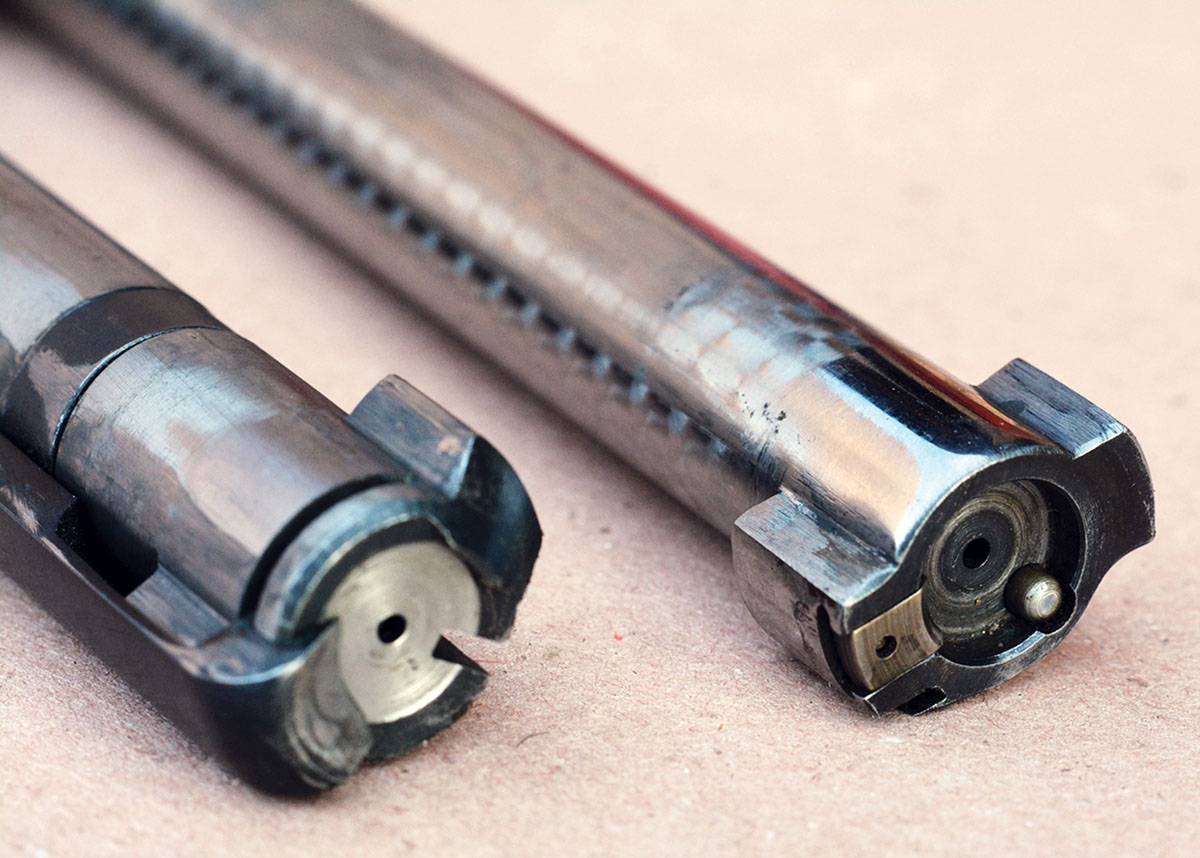

The original Winchester pre-’64 Model 70 (top) was a hugely respected rifle and featured solid machined steel, control-round feeding and boasted of high quality, while the post-’64 Model 70 (bottom) was a push-feed system and had many other changes in design and lower quality.

As indicated, the original Model 70 was a no-nonsense rifle that offered extreme reliability and high quality. Briefly, it boasted of many desirable features including a receiver that was fully machined from chrome-moly bar stock with integral recoil lug, forged one-piece chrome-moly bolt, swept bolt handle that served as a third locking lug in the event of an overload (but does not make contact), Mauser-style claw extractor and blade ejector for control-round feeding, three-position wing safety and a fabulous trigger that was rugged, ultra reliable, crisp and fully adjustable. Naturally, it featured a hinged floorplate and the action was secured to the stock via three guard screws, plus a fourth screw secured the barrel to reduce vibrations (not included on Featherweight rifles). The cut-rifled barrels boasted of match-grade quality. However, the Model 70 was not designed to be produced with high efficiency or low cost, rather, it required considerable machining operations that resulted in many man hours, gave considerable tooling wear and required a large amount of raw material to produce one rifle. For instance, the receiver started life as bar stock weighing 120 ounces and required around 75 machining operations to bring it to its final weight of 19.3 ounces.

The pre-’64 Model 70 bolt (left) was machined from solid steel and featured a powerful claw extractor. The post-’64 Model 70 bolt (right) was two-piece and featured a counter-bored bolt face with a rotating extractor and plunger ejector.

With high costs for material and labor, and literally losing money on every rifle built, Winchester had to do something to reduce manufacturing costs. For example, during World War II, Remington produced many arms for U.S. and allied forces and learned how to accomplish that with high volume and at economical prices. After the war, they applied this same technology to produce civilian sporting guns. Their post-war “Reconversion and Modernization Program” resulted in the design and production of the Models 721, 722 and 725 rifles that evolved into the Model 700 in 1962. The round receiver used less material, required fewer machining operations and completed rifles were offered at roughly 30 percent lower price than the competition and Remington was enjoying a respectable profit. Despite much internal turmoil, Winchester decided to redesign the Model 70 for the sole purpose of reducing manufacturing costs and becoming profitable.

When the new Model 70 was unveiled in 1964, it immediately was subjected to heavy criticism by reputable shooters, hunters and gun writers. For example, noted writer Jack O’Connor said he “screamed” at the sight of the new rifle. Additionally, in The Rifle Book, O’Connor stated, “I saw the pilot model of the ‘New Model 70.’ At the first glimpse I like to fell into a swoon. The action was simplified, the trigger guard and floorplate made of flimsy-looking one-piece stamping. The stock had stodgy lines and no checkering, and the barrel channel was routed out so much that a herd of cockroaches could hold a ball below the barrel. On my first glimpse of the ‘New Model 70’ I was surrounded by the designers and by Winchester brass. I told them the creation would not sell, that it was one of the ugliest rifles I had ever seen.” Elmer Keith was one of the designers of the original pre-’64 Model 70 and he too completely denounced the post-’64 version both for its design, but mostly for its poor quality.

The post-’64 Model 70 boasts of a simple design that is easily field stripped.

In spite of the above scathing remarks, sales for the post-’64 Model 70 were strong. For example, for the first 10 years, more than 370,000 rifles were sold and after 18 years, more than 817,000 guns were sold. By comparison, sales for the pre-’64 Model 70 over 28 years were less than 600,000. Clearly, the average deer hunter, whoever that may be, was happy with the overall performance and price of the new rifle. Nonetheless, the post-’64 rifle had a few issues, some rather serious, but first let’s look at its design and function.

The post-’64 Model 70 shared a similar profile as its pre-’64 counterpart including a hinged floorplate, swept bolt handle and three-position wing safety.

The new Model 70 receiver was shaped similar to the original rifle with flat bottom, forward-recoil lug, three guard screws, etc., but was approximately 1⁄8-inch longer. Rather than being machined, Winchester referred to the receiver as “precision forged,” but is more commonly known as a solid one-piece forging. The heat treatment was only applied to key areas of the receiver that needed greater strength and hardening to prevent wear. In theory, this reduced costs, but also limited warping. Many of the smaller parts were now cast, but the overall metal work was very rough and unpolished, leaving the impression of a poor-quality rifle.

The original pre-’64 Model 70 was built with just one overall action length. However, during the post-’64 years it was offered in three action lengths including (top to bottom): 30-06, 308 Winchester and WSSM or Super Short length.

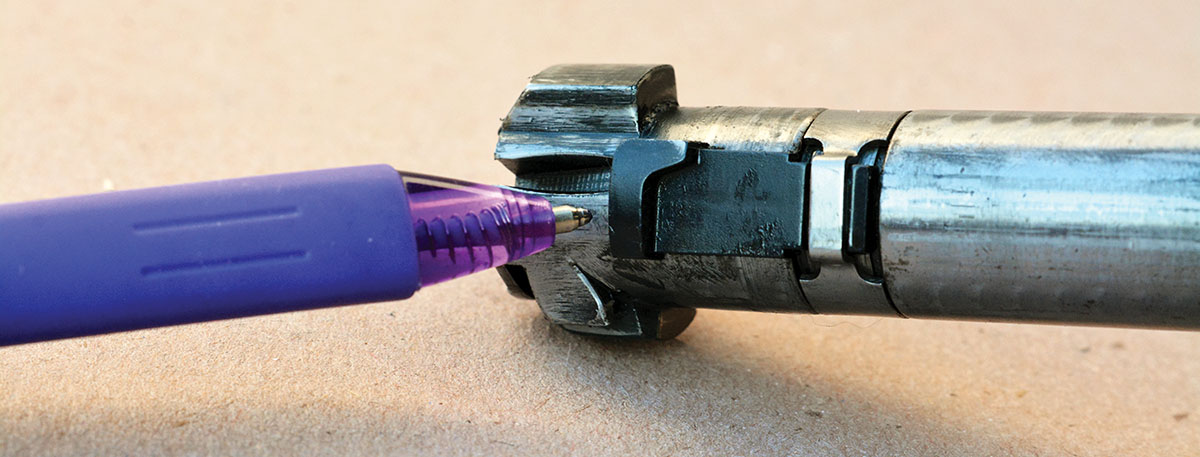

The bolt was now a two-piece arrangement. In essence, the bolt body and twin-locking lugs are constructed from one-piece of hardened steel; however, the breech end of the bolt body was knurled with a step down arrangement. The bolt handle featured a ring at the opposite end of the knob, which was placed over the knurled bolt body and swaged in place, soldered and then polished smooth. This can be very difficult to see, but by looking closely at the bolt body just forward of the bolt handle, a faint line can be seen around the bolt, which is the junction of the bolt body and bolt handle. Normally, this arrangement works reliably; however, from time to time, it can become loose (when stressed or not properly installed at the factory) and will leave the rifle inoperable. For this reason, I prefer to flatten two sides of the junction, then weld and re-contour it on my dangerous-game rifles. The new bolt face was countersunk and the coned barrel breech found on the original Model 70 was changed to a square-faced type. The extractor was rotating type and the plunger-style ejector was mounted in the bolt face. This arrangement is commonly known as a push-feed system. Incidentally, the lock time was reduced from 3.5 milliseconds (ms) for the pre-’64 version to 3.0 ms.

The Model 70 Classic action is similar to pre-’64 rifles, but offers improved gas protection and other notable improvements.

A few other problems that needed to be addressed included the absence of an anti-bind arrangement resulting in less than smooth bolt operation. The bolt stop was prone to breakage when the rifle was operated with the strength and speed that can be necessary with dangerous-game rifles. When this occurs, the bolt comes right out of the rifle, which is a less-than-desirable situation when a wounded brown bear is just a few feet away (and has actually happened)! The floorplate was constructed of a flimsy alloy, but generally, the overall fit of the parts was poor.

Just as O’Connor indicated, the stock was truly ugly, as the wood quality was poor, the pressed checkering looked cheap and the fit was atrocious!

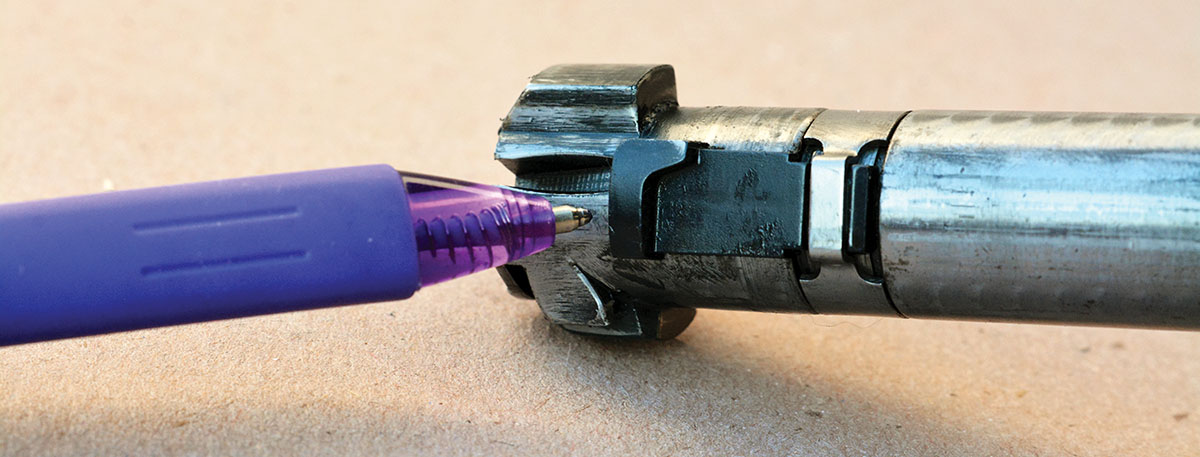

The Model 70 Classic offers a gas block that serves to further protect shooters in the event of a ruptured primer or blown case.

Beginning in 1968, or with a serial number of around 866,000, Winchester began to address those problems by improving reliability and appearance. For example, an anti-bind device was added to the right locking lug, the floorplate was changed to steel and the magazine follower was redesigned to improve function. There was additional focus on general quality, with an effort to improve parts fitment and quality. Reliability was notably improved. Cosmetically, Winchester began to properly polish the metal for a deep luster blue finish and the American black walnut stock was attractively finished and featured cut checkering. Incidentally, the barrel channel was fit much more closely and a small barrel pressure point was placed just behind the forend tip to help reduce barrel vibrations.

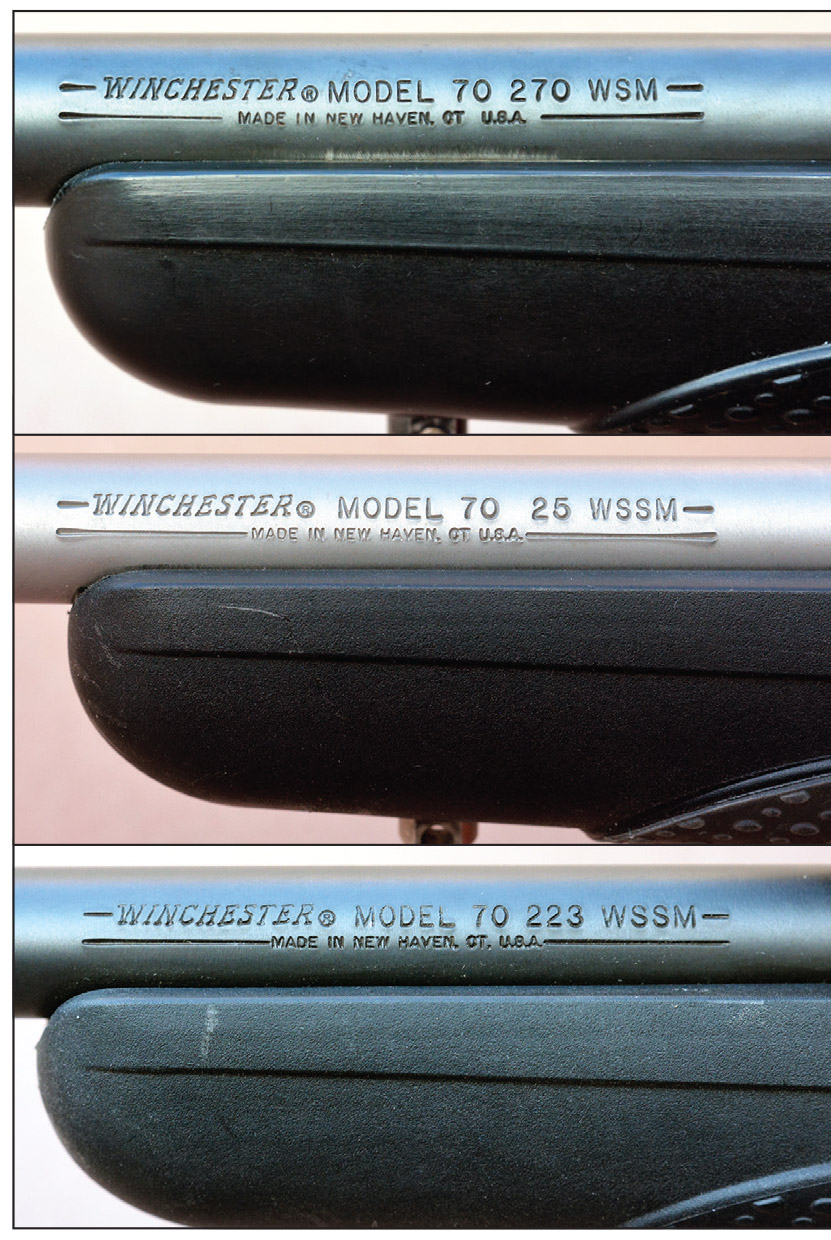

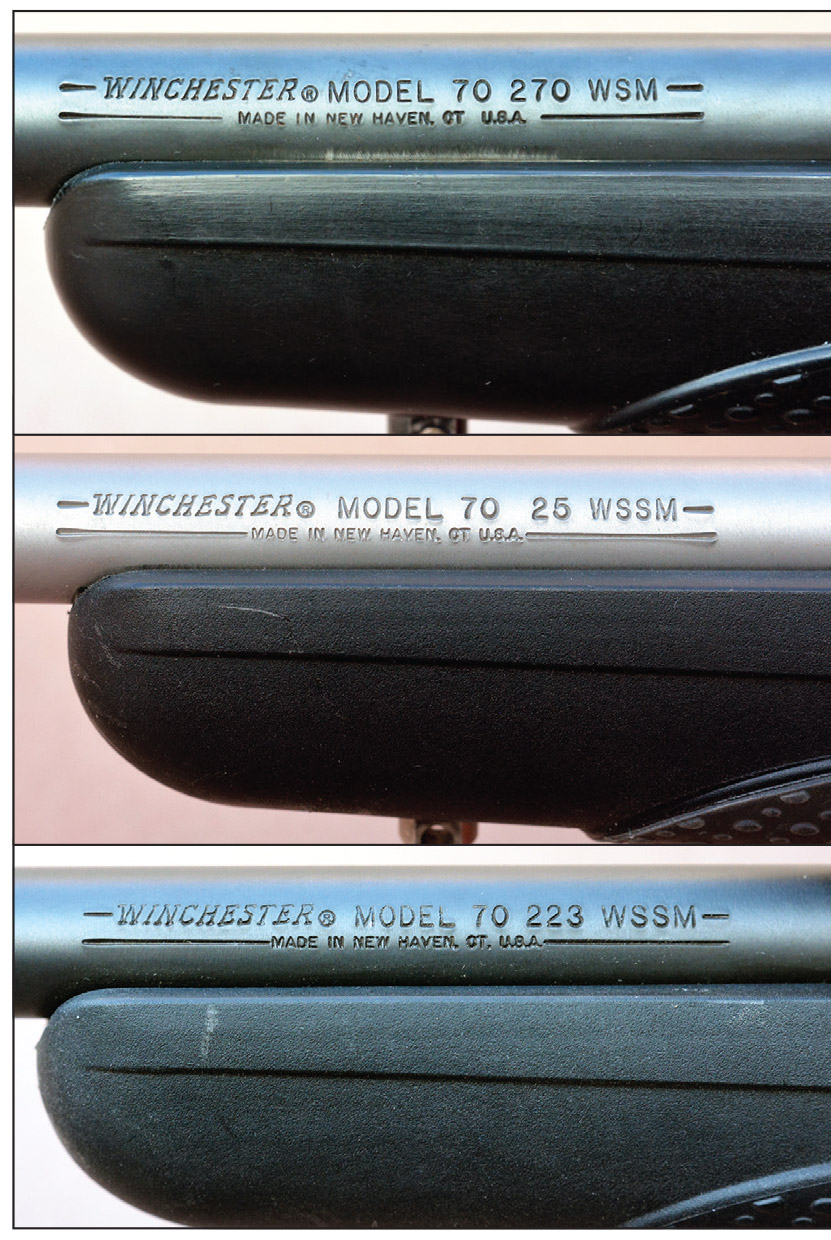

During the post-’64 years, the Model 70 was used to introduce many new cartridges such as the 270 WSM, 25 WSSM, 223 WSSM and many others.

Generally speaking, most shooters and deer hunters were satisfied with the appearance, accuracy and reliability of the Model 70. However, there was still great demand for the control-round feed system with the strong claw-style extractor and the “cartridge control” factor. Beginning in 1986, Winchester (USRAC) began developing a control-round feed rifle, but was only available on a limited basis. However, it was added to the product line in 1992 and dubbed the “Classic” Model in 1994. This was a truly great design, as it was similar to the pre-’64 Model 70, but had some notable changes. The anti-bind device remained on the right locking lug (while the pre-’64 version is a part of the bolt body). A gas block was mounted to the extractor collar and prevented gases from ruptured cases from traveling down the left raceway and there are two ports that divert gases from inside the bolt body down into the magazine. The Classic action received high marks for protecting the shooter from gases and is a notable improvement over the pre-’64 version.

Like any company trying to keep costs in check, once in a while these actions required minor fitting and polishing of parts to get that ultra-smooth operation. One problem that occasionally surfaced was poor extractor fit and or quality, which were known to break, but Winchester soon changed to a top-quality fully CNC-machined version offered by Williams Firearms.

The pre-’64 Model 70 Featherweight (left) was a popular rifle; however, the post-’64 Model 70 Classic Featherweight (right) featured a stylish classic stock with custom style cut-checkering and has enjoyed huge popularity.

Despite the control-round feed Classic Model 70s being very well received, there was still demand for a less costly, push feed-style rifle, which appeared in many variations, including the price conscious Black Shadow that was void of a hinged floorplate. Uniquely, there were Model 70s that appealed to shooters on a very tight budget, varmint and target shooters, discriminating riflemen wanting a custom-grade gun, or hunters wanting a well-designed dangerous-game rifle.

Unlike the pre-’64 Model 70 that was only offered in one action length from 22 Hornet to 375 H&H Magnum with a one-size-fits-all approach, the post-’64 rifle was offered in three action lengths that included 30-06, 308 Winchester and the Super Short for the WSSM cartridges. This was a much better approach that resulted in a more efficient rifle that could be better matched to a given cartridge. Winchester introduced several new cartridges during the post-’64 era including the 225 Winchester, 223, 243 and 25 WSSM, 270, 7mm, 300 and 325 WSM.

Post-’64 barrels were hammer forged (pre-’64 rifles were cut rifled), which can be very accurate. However, suffice it to say that current cold hammer forging manufacturing technology is notably better than it was during the 1960s and 70s. Nonetheless, I have rifles from virtually every era that have given good accuracy.

For reasons that cannot be discussed today, the historic New Haven, Connecticut, plant was closed in March 2006, which was not entirely the fault of Winchester, and ended production of the Model 70, Model 94 and other guns. Winchester rifles are an integral part of U.S. culture and this was indeed a sad day. At closing, around 2,345,000 post-’64 Model 70s were produced. In spite of various obstacles, the new Model 70 had once again become a great rifle.

Post-’64 Model 70 rifles have all featured hammer-forged barrels, which can be accurate. This Model 70 Classic Laredo LRH chambered in 300 Winchester Magnum produced this impressive group at 200 yards using Hornady Precision Hunter ammunition containing the 200-grain ELD-X bullet.

After contracts had expired, Model 70 production resumed in 2008 in the much more gun-friendly manufacturing state of South Carolina, but was now produced in the FN plant (a subsidiary). These were good quality rifles, with high-quality barrels and good overall machining. However, one notable change was the fabulous trigger that was famously rugged and ultra-reliable, was now replaced with the “MOA” trigger system that is housed, adjustable for pull (no lower than 3 pounds) and aftertravel. Incidentally, the floorplate is now one-piece, the middle guard screw has been eliminated and the barrel is free-floating.

As indicated, by 2013, assembly was moved to Portugal and in 2015, manufacture was likewise moved. While it may be disappointing to see an iconic U.S. rifle manufactured overseas, it’s largely the result of the domestic manufacturing climate that we now live in. At least it remains in production and is available, which is a tribute to just how good and timeless the Model 70 is.

I recently had the opportunity to work with a newly manufactured Model 70 Featherweight chambered in 30-06. The barrel is marked “Imported by BACO, Inc., Morgan, Utah-Made in Portugal by Browning Viana.” In addition to functioning flawlessly, it consistently produced just under 1-inch groups using non-premium U.S.-manufactured factory loads from Winchester and Federal. Despite not being manufactured in the U.S., the latest Model 70 is a good quality rifle.

With 89 years of rich history and surviving changing times, the Model 70 has earned a loyal following and remains a worthy field rifle.

Classic Model 70 rifles are widely popular and sought after. Examples include: (1) Laredo LRH 300 Winchester Magnum, (2) Featherweight 280 Remington, (3) Stainless Steel 25 WSSM and (4) Featherweight Jack O’Connor Tribute Rifle chambered in 270 Winchester.