Notes on Rifle Suppressors

Conclusion

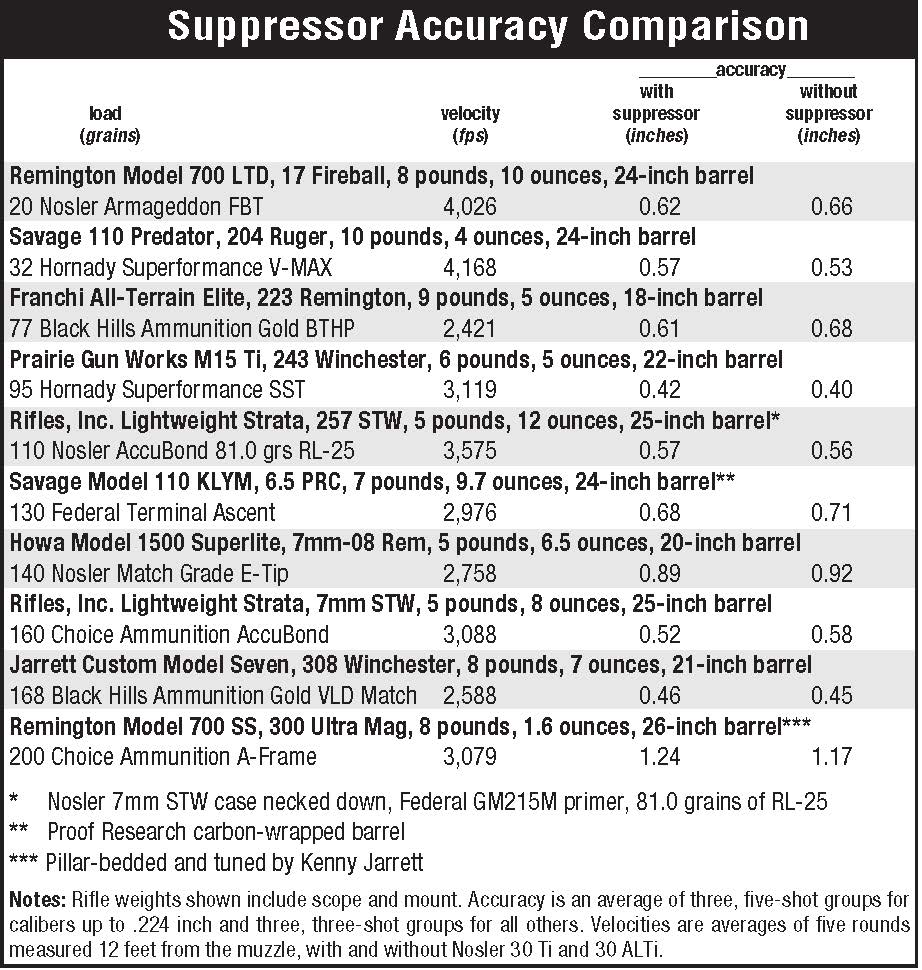

feature By: Layne Simpson | May, 25

User-Serviceable Versus Sealed

As the word indicates, a sealed suppressor is of welded construction and it cannot be taken apart by its user. This design is usually preferred by the military and by civilians who participate in various rifle competitions. I would be surprised to see a serious PRS guy using anything else.

User-serviceable means the interior parts of a suppressor can be easily accessed. This is usually done by removing a threaded end cap or by separating the two parts of the main tube which are threaded together. With that done, the baffle column or stack can be removed for cleaning. If the suppressor has been used a great deal, carbon buildup can make its baffles difficult to remove. Spraying the inside with Kroil penetrating oil will usually loosen things in short order and a wooden dowel from the hardware store will push them out without damage. The oil is easily removed during cleaning. Some companies offer a baffle removal tool for their suppressors.

Cleaning the Can

Opinions on how often a suppressor should be cleaned range from never to just often enough. From a practical point of view along with a pinch of common sense, cleaning is greatly dependent on the cartridge used and the level of fouling it leaves behind. The

Moving to the opposite extreme from the 22 Long Rifle, the 223 Remington can hardly be described as an offender. A friend lives in prime prairie dog country and for many years he has spent a lot of time trying to keep their population in check. While not the best of record keepers, he estimates that over 60,000 rounds of 223 handloads have gone through his suppressor and he has yet to clean it a single time. Due to a combination of small powder charge and high muzzle pressure, the 223 leaves very little carbon fouling behind. The same applies to other cartridges in the family such as the 222 Remington, 222 Remington Magnum, 204 Ruger and 17 Remington.

Bigger cartridges that burn more powder foul worse but even then it is seldom enough to cause concern. Seth Swerczek, the Marketing Communications Manager at Hornady, has been competing in PRS competition for quite a few years and I believe he still uses the 6.5 Creedmoor. His rifles wear Thunder Beast Ultra 5 and Ultra 7 steel suppressors. While writing this I asked how often he cleaned them and he replied not very often, maybe every 5,000 rounds or so. Keep in mind the fact that I am writing about the use of suppressors on rifles. Handguns chambered for such rounds as 9mm Luger and 10mm Auto are another story entirely and suppressors used on them may have to be cleaned quite often. Switch to lead-alloy bullets and a suppressor will have to be cleaned as often, and sometimes even more so, than when it is subjected to 22 rimfire fouling.

Suppressor Alignment Check Rods

If the threaded shank at the muzzle of a barrel is not concentric with the bore, a bullet can strike the baffles, the end cap and even the body of a suppressor. If the damage is bad enough a replacement will have to be purchased and that means another merry-go-around with the Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF), not to mention another $200 tax stamp*. A barrel threaded by a good gunsmith who is experienced in doing so will be fine. Most factory rifles I have checked were okay but a few were not and could not be used with a suppressor. Mass-produced work can vary so better to be on the safe side by checking alignment between the bore of a barrel and the attached suppressor prior to shooting the rifle. This is done with precision-ground, stainless steel alignment rods of bore diameter (not groove diameter) for specific calibers. Mine were made by Geissele Automatics and they came from Brownells. The common sizes are 5.56mm, 6mm, 6.5mm and 7.62mm. Using one is easy.

First make sure the rifle is not loaded. Then with the suppressor firmly attached to the barrel, insert the rod deeply enough for its end to rest flush with the end surface of the suppressor. To avoid possibly bumping the end of the rod against the muzzle crown of the barrel, insert it from the breech end, cover the muzzle with a finger and tilt the rifle to get the rod moving. If the rod rests dead center of the hole in the suppressor or is only a bit off you are good to go. If not, you may experience the dreaded bullet strike when firing the rifle.

The fix is no more difficult than sending the barreled action to a good gunsmith who will chop off the crooked threaded section and properly rethread. When the barrel returns, it will be just over a half inch shorter but no elk, deer or prairie dog will know the difference.

As far as I know, alignment check rods are not available for other calibers but a bit of looking around may find something that works. According to my Starrett micrometer, the diameter of a Dewey cleaning rod I have is .2684 inch for a snug-enough fit with the barrels my rifles in 270 Winchester. A .248-inch cleaning rod by an unknown maker works just fine in my 25-06, 257 Roberts and 257 STW. For 7mm rifles, I use a .258-inch cleaning rod increased to .278 inch by a few wraps of masking tape spaced a foot or so apart. Keep adding tape until the rod slides wobble-free down the bore. Last but certainly not least in importance, be double-certain the rod is removed from the barrel prior to firing the rifle.

Barrel and Suppressor Thread Maintenance

After each shooting session, barrel and suppressor threads should be scrubbed with an old toothbrush dipped in powder solvent and then wiped with a rag or paper towel. A thread protector is then attached to the barrel and the suppressor is stowed in its bag. If a unit does not come with one, an old wool sock works fine. Prior to attaching the suppressor, a light coat of special grease should be applied to the barrel threads. This assumes it will be subjected to a lot of rapid-fire shooting. I enjoy participating in 2-Gun and 3-Gun matches and race through the rifle stages with a Ruger AR-556. As many as 40 to 50 rounds can be quickly fired on a stage and I am told that temperature of my trusty suppressor is probably well over 800 degrees. Prairie dog shooting on hot day can also heat up a can. There are other possible issues. A friend of mine absentmindedly left a suppressor on a rifle in his gun room for over two years and when finally deciding to remove it from the rifle it had seized in place.

Careful – It’s Hot!

I watched video of a shooter doing multiple 30-round magazine dumps with full-auto AR-15 and the suppressor became hot enough to glow a bright red. Few shooters will experience such nonsense, but a suppressor still often becomes too hot to the touch so snatch one of the wife’s hot pan mitts or pads and use it when removing it from the unloaded rifle. When I had only one suppressor and was testing several rifles at the range, the pot holder allowed me to quickly make the switch from rifle to rifle. When I am shooting only one gun, the suppressor is usually cool enough to remove from the rifle by the time I load all my gear in truck for the trip back home.

There are occasions when I consider a cover made of heat-resistant fabric to be essential. In addition to protection from an accidental painful touch with bare skin, it eliminates or reduces heat waves that cause the target to wiggle around when a scope is used. A good cover also adds a bit of sound suppression. I always use one when shooting prairie dogs and when competing in 3-Gun matches with an AR-15. I don’t use one when big-game hunting because not enough shots are taken to heat up the can. The same goes when calling in coyotes.

I have yet to try a cover that does not creep forward on the suppressor due to recoil. My cover with metal buckles and Velcro straps can be cinched down tight enough to make a boa constrictor turn blue but it begins to move forward at about 20 rounds of 308 Winchester. My fix is a piece of Kevlar Aramid paracord with one end looped through its three buckles and the other end long enough to wrap around the barrel several times and tie off against the rear end of the suppressor.

It is extremely important to remember that a suppressor can vibrate loose during a shooting session and it should be checked for tightness every 20 rounds or so. A cover makes doing so quick and pain-free to do. It is also possible for a suppressor to become a bit loose in the field when no shots are fired so be sure and check it there as well.

Barrel Length and Cartridge Recommendations

When a cartridge fires, pressure peaks quickly and has gradually decreased as a bullet exits the barrel. In other words, pressure is much higher near the chamber than at the muzzle of the barrel. As barrel length decreases, muzzle pressure increases and that’s where a suppressor hangs out. All suppressors are designed to safely handle a certain level of pressure and this is why each is usually given a minimum barrel length rating by its maker. As an example, recommended minimum barrel length for the Nosler SR-22Ti is 10 inches which means it would work fine on a T/C Contender handgun with a 10-inch barrel in 223 Remington or an XP-100 in 22-250. Moving to the Nosler SR-30Ti, it is 12 inches for 308 Winchester and smaller and 18 inches for larger cartridges. Some makers also specify maximum cartridge size. For the SR-22Ti it is the 22-250 and 220 Swift and for the SR-30Ti it is the 30-378 Weatherby Magnum.

Earlier I mentioned hunting with a guide in Scotland who commented about going into a number of stores in his country and buying a can of beans for dinner and a can for his rifle. No paperwork, no questions asked and no ridiculously long wait. He went on to remind me that the United States is still in the Stone Age regarding suppressor ownership. Hopefully that will eventually change due to the Hearing Protection Act introduced by Congressman Matt Salmon of Arizona back in 2015. In 2021 it was reintroduced by 15 Senate Republicans and hopefully it will eventually be adopted. But don’t hold your breath because like many other common-sense laws, it is heavily opposed.

* Editor’s Note: Some companies will allow you to return the suppressor to be rebuilt after a baffle strike. This avoids the lengthy wait time for a new suppressor and going through the paperwork and process to attain a new tax stamp.