Light Gunsmithing

Early Greener G.P. Actions

column By: Gil Sengel | May, 25

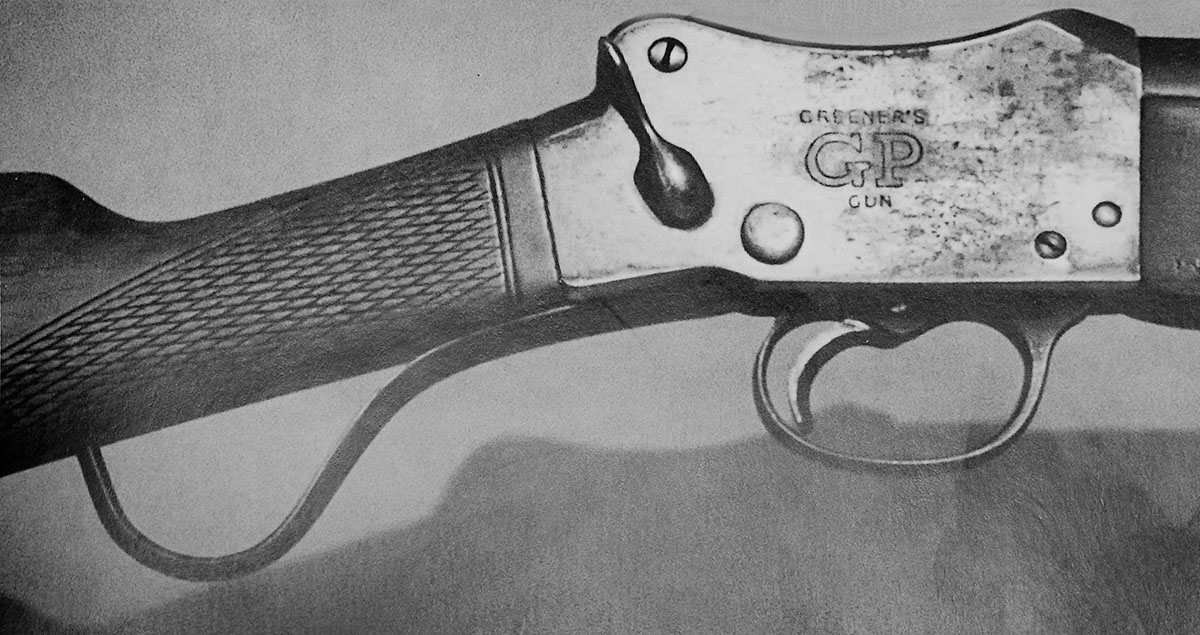

William Greener’s second son was named William Wellington Greener. He is the well-known W.W. Greener, who wrote several books on guns and gun making, including the classic The Gun and Its Development, which belongs in the library of every serious firearms student. W.W. Greener died in 1921, and his son Harry Greener continued to design specialty and inexpensive guns for the company. Two of these were the Greener Police Gun and the Greener General Purpose (G.P.) gun.

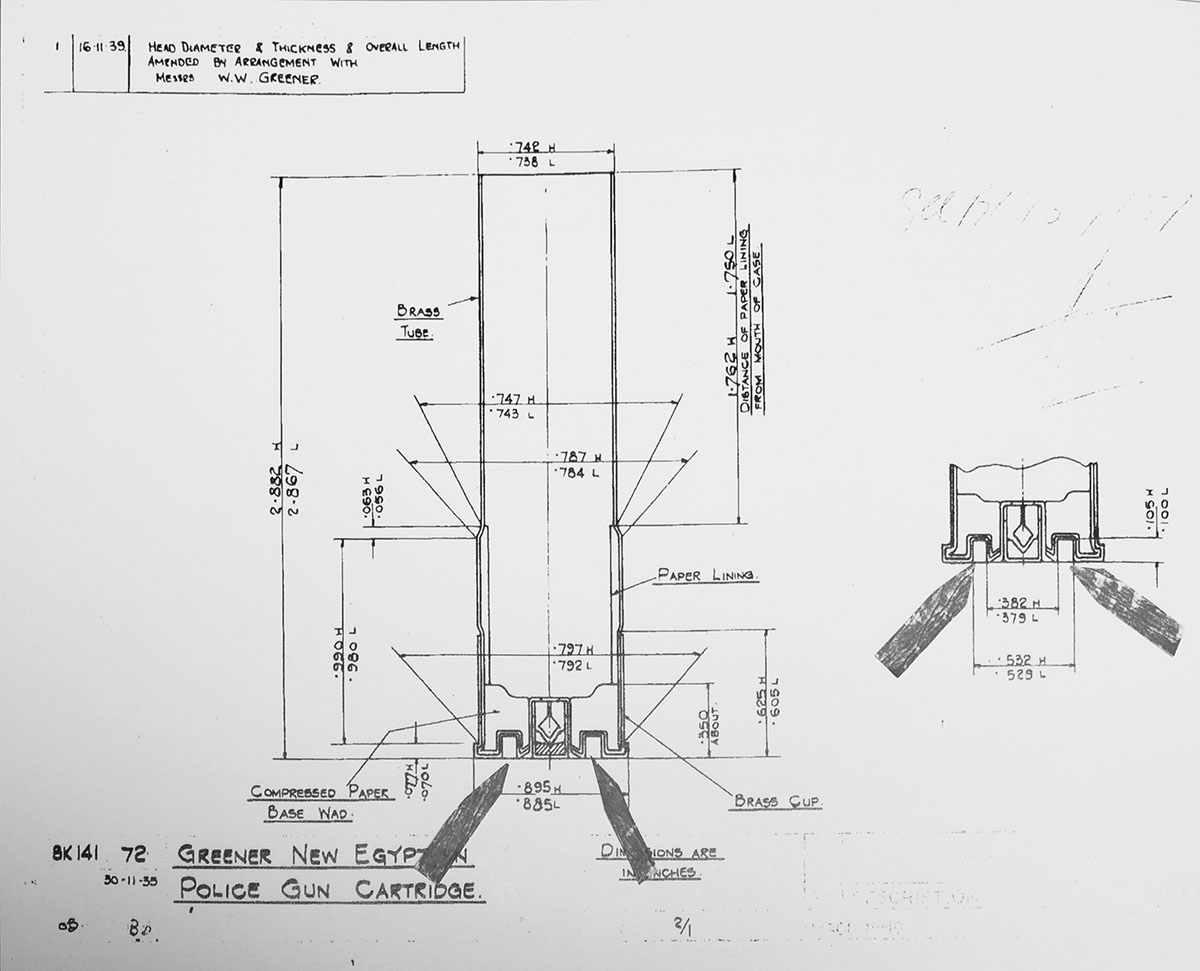

The Greener Police Gun was first made in 1922 to satisfy a contract with the Egyptian government for police weapons. Intended for riot control, it was a shotgun built on a modified Martini action – like that of Martini-Henry military rifles produced by W.W. Greener in the 1860s. However, corruption was endemic in Egypt at the time, so a special 13-gauge cartridge was used in the Police Gun, Mark I, to hopefully keep the guns out of criminal and terrorist hands. If you can’t control the guns, control the ammunition. Sound familiar?

The chronicles tell us Egypt and some two dozen other countries bought about 60,000 Police Guns. Greener thought the gun might also make a good shotgun for small game and varmints, much like the American farm gun. These sporting-style guns don’t seem to have been imported into the U.S., perhaps because they were higher priced than American-made products. Greener called them General Purpose Shotguns or G.P. for short. Unfortunately, extended use caused serious problems with mechanical safety. More on this later.

As riflefolk, we are not particularly excited by scatterguns, but therein lies an interesting story. When the Police Gun first became available on the surplus market, some very rough examples appeared at a gun show. They had a strange lever located at the right, rear side of the receiver. Martini military rifles and Cadet trainers did not have this. The fellow at the table said it was a safety.

Dad owned what is now called a pre-’64 Model 70 in 22 Hornet. When I suggested he might trade it for a 222 Remington, he looked at me like someone who had broken into the house and was stealing the silver (except we didn’t have any silver)!

Suggesting that he might think about it, he said, “Okay. No.” When I whined that he said he would think about it, he replied, “I did. I just think fast!” Resigned to the fact that a 222 Remington was not in my near future, it was a total surprise when Grandpa handed me a cloth gun case for my birthday a few months later. It must be a 222 Remington! I was elated until the rifle was pulled from the case. There appeared the ugliest rifle I had ever seen.

Grandpa had found a rusty Greener Police Gun somewhere and purchased one of the $10 22 barrels advertised in the American Rifleman, had the local gunsmith modify the extractor, then fit and chamber the barrel to 219 Zipper. Open sights were dovetailed on the receiver, sandblasted and the metal slopped with cold blue.

One would guess this Frankenstein assembly was not very accurate, but it shot superbly. Dad’s loading manual showed 50-grain bullets and 22.0 grains of IMR-4198, giving 3,200 fps; 26.0 grains of IMR-3031, yielding 3,300 fps. That was faster than the 222 Remington factory loads! The Martini printed 50-grain Sierra Blitz bullets well under two inches at 100 yards and three inches or less at 200 yards. When I finally got a 222 Remington, a Savage Model 340, it had open sights and wouldn’t shoot as well as the ugly Martini until a scope was installed.

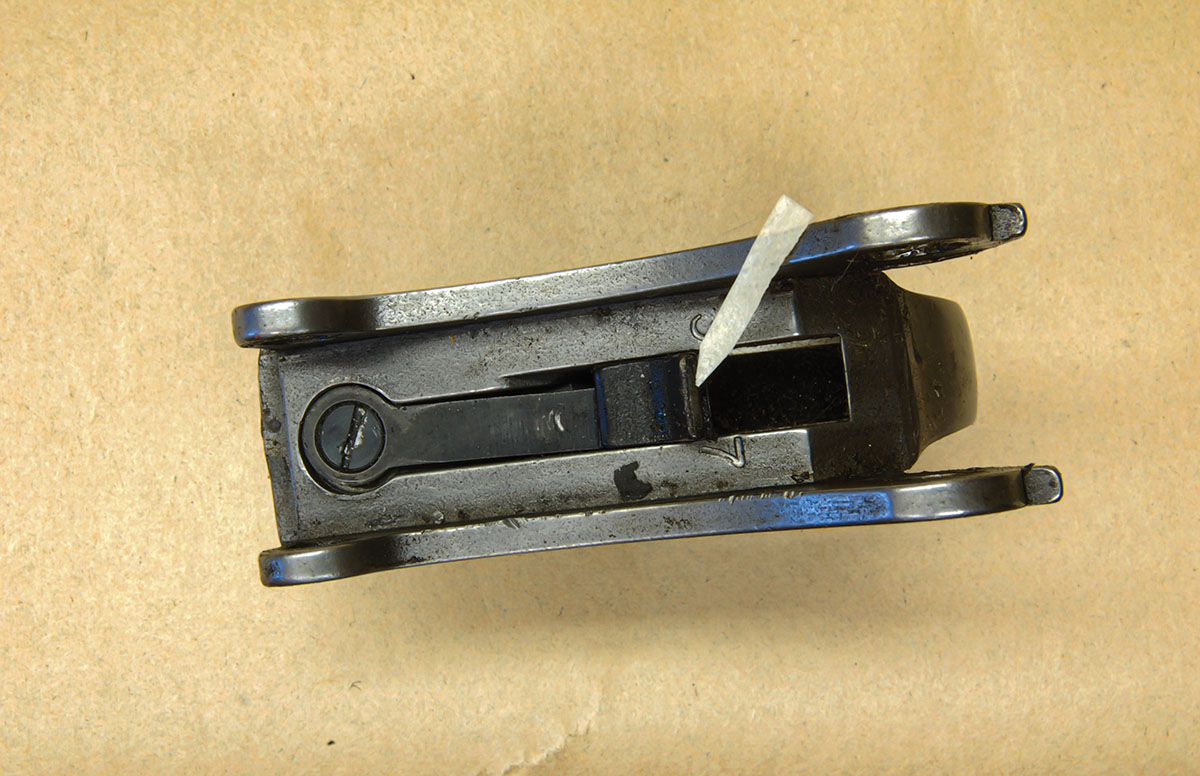

Operation of the safety is obvious when the trigger guard and cocking mechanism are dropped out of the receiver. There is a part called the cocking piece attached to the action opening lever. It has three arms. When the action lever is pushed down, dropping the breechblock, one arm contacts the striker, pushing it back to the cocked position. The end of the second arm drops into the sear notch on the trigger, holding the striker in the cocked position. The third arm enters a milled notch in the safety rod but does not touch it.

The safety lever is pulled backward to engage. This rotates the notch in the safety rod and brings its bottom surface into contact with the third arm, pushing it down slightly. This, in turn, causes the first arm to force the striker rearward and the second arm to lift out of contact with the trigger. The rifle is now certainly on “safe” and will not fire, but the trigger is free to move, controlled only by its return spring.

The mainspring of the Martini is very short and powerful. The camming surface on the safety rod is small. Since it must push against the entire spring pressure to engage, it will wear if the safety is used very much. This, in turn, means the sear surfaces of the second cocking piece arm and trigger separate by less and less. Eventually, the wear will cause the surfaces to not separate completely but touch ever so lightly. If carrying or handling causes the trigger to move out of (or nearly out of) the sear notch, when the pressure is released the trigger return spring may not be strong enough to re-engage the sear surfaces. If not completely engaged, the trigger pull becomes short, light and not at all Martini-like. No engagement results in a loud noise when the safety is released.

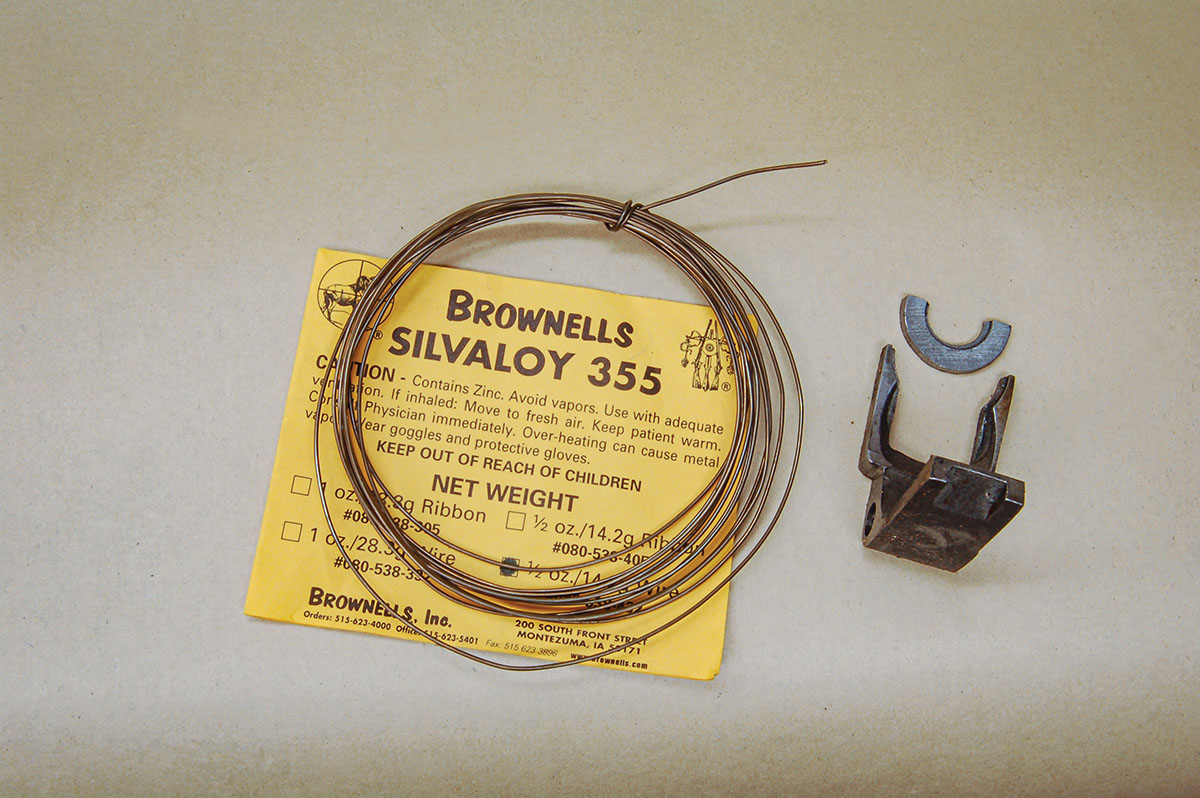

At least the old 219 Zipper showed that shotguns can be useful – if made into rifles! Next time, we will use a much newer Greener G.P. shotgun action and make it into, well, almost a rifle.