Bringing up the subject of bolt action rifles with “control round feeding” versus “push feed” is always a good way to start a lively discussion among rifleman and hunters. Personal experience includes detailed study of various designs, repairing and gunsmithing, and using both types in adverse conditions and in high volume shooting. I have watched many of these guns - both domestic and foreign - being manufactured. My opinions are based on experience and are not biased toward one or the other. There are pros and cons to each. Right or wrong, I’m going to stick my neck out with a candid discussion. My only regret is that I wish I had more space for greater discussion of details. Let’s begin with a brief history of both action types, the focus will be primarily on popular rifles that have been, or are readily available, in the United States.

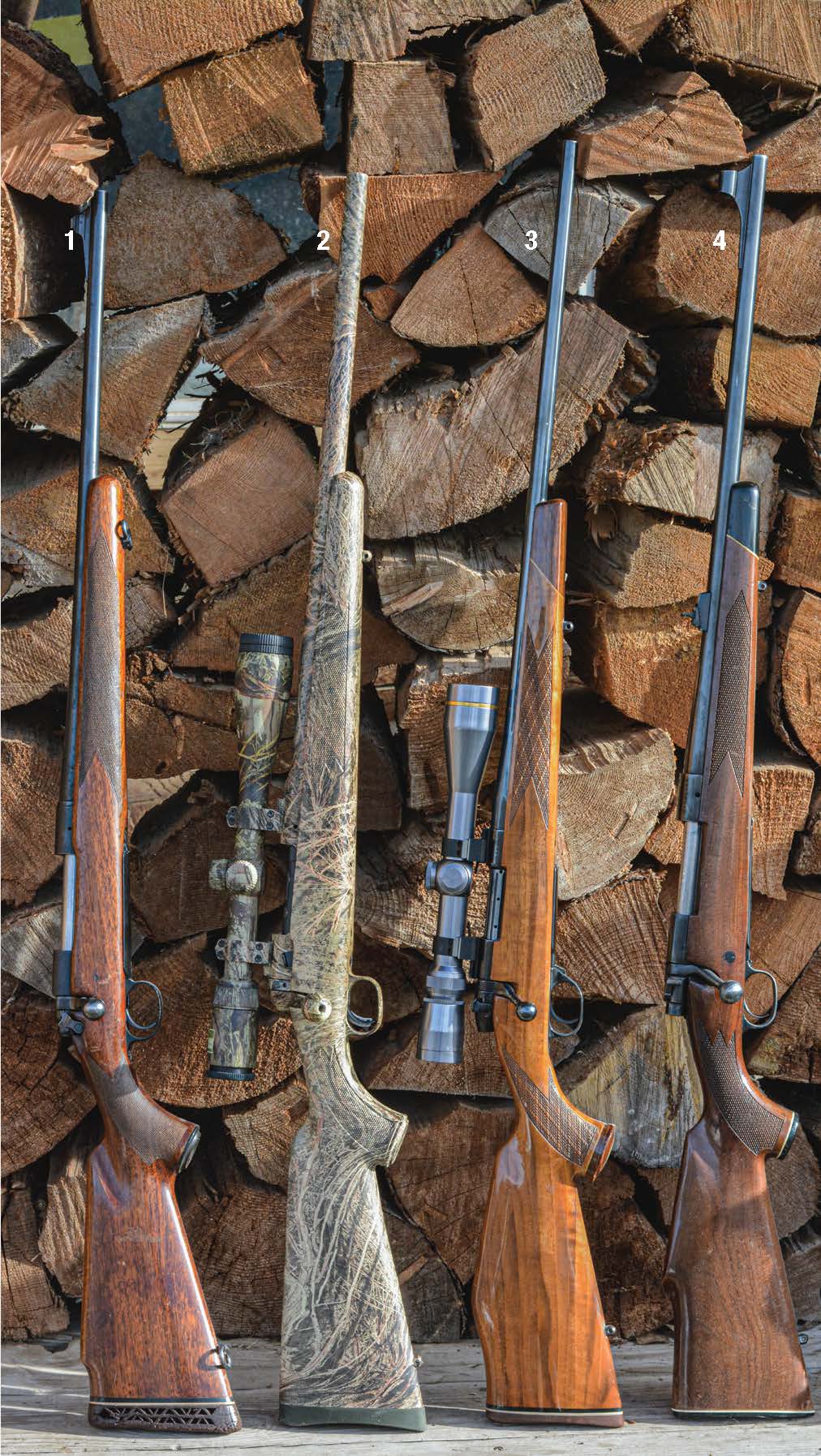

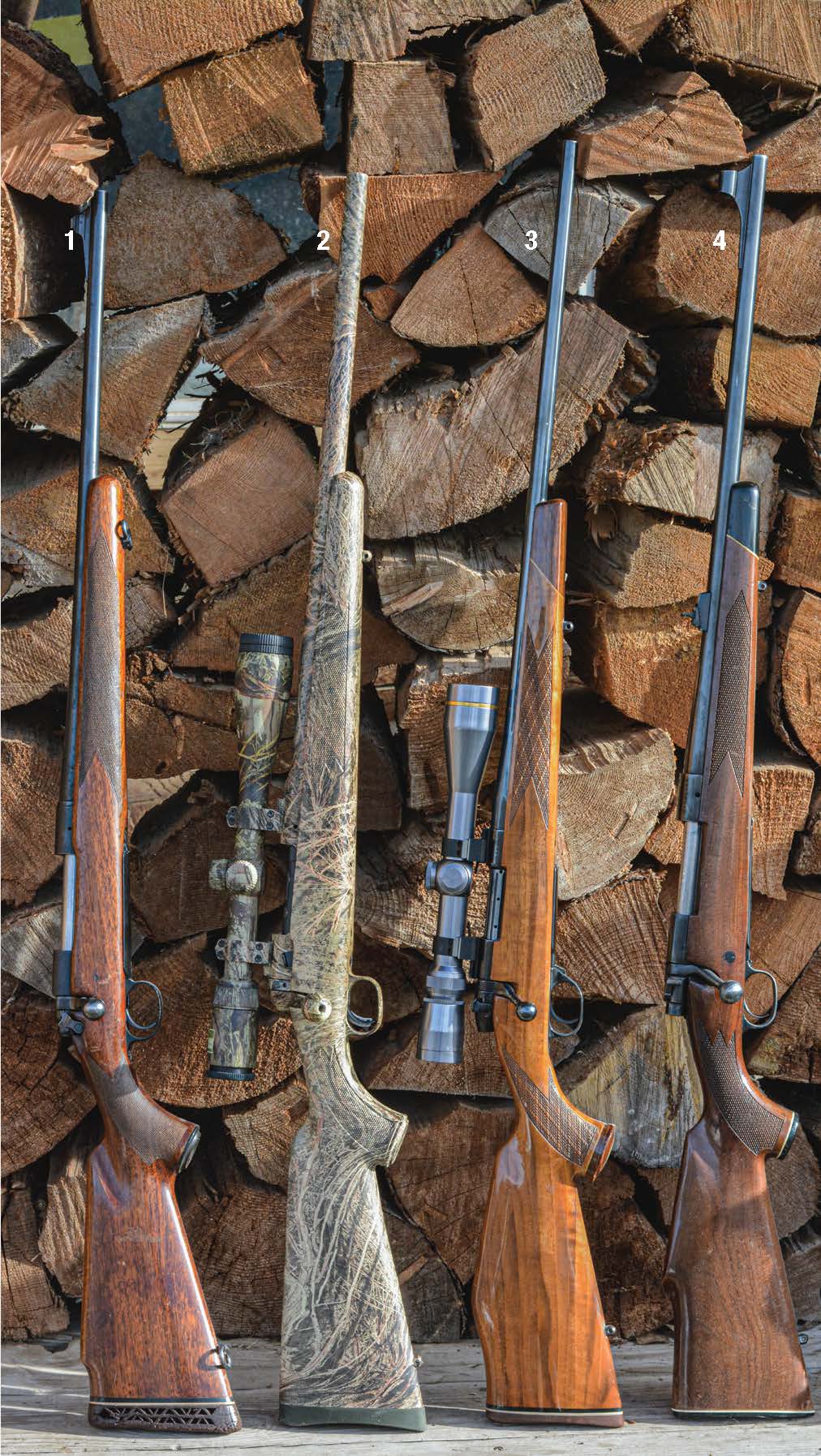

Typical rifles with push feed actions include: (1) Remington 725 (later becoming the Model 700), (2) Savage Model 10, (3) Weatherby Mark V and (4) Winchester post-’64 Model 70.

As a general definition, bolt-action rifles with control-round feeding, strip the cartridge from the magazine while the extractor holds the cartridge via the rim (or extractor slot) against the bolt face, and literally holds or controls the cartridge. Once the cartridge is held by the bolt, it can be chambered - or the bolt can be pulled back and the cartridge ejected (usually via a blade ejector). In other words, if the bolt is operated slowly, the cases/cartridges will barely eject, but if the bolt is pulled back with some speed, cases will eject well away from the rifle. The shooter has complete control of the cartridge.

The Mauser 98 is the world’s most popular bolt action rifle and features control round feed. It has been used in both military and sporting applications and is incredibly reliable.

Push feed systems generally strip the cartridge from the magazine, but it stays in front of the extractor until it is fully chambered at which time the extractor (usually a spring loaded rotating style, but not

The Winchester pre-’64 Model 70 (top) is a control round feed action, but to cut manufacturing costs the post-’64 Model 70 (bottom) became a push feed design.

always) engages over the cartridge rim (or into the extractor slot) just as the bolt is being closed. While there are exceptions, usually push feed systems feature a plunger-style coil spring-loaded ejector. When the bolt is opened and the fired case is extracted and pulled backward, the mouth of the case clears the receiver ring and it is automatically ejected. (There are exceptions, such as period Sako rifles that featured rotating extractors and blade ejectors that were a push feed system, but the shooter had control of the mechanical ejection that is not common with push feed designs.)

The modern bolt action rifle really began with the legendary Mauser 98 and variants, which is easily the world’s most popular bolt action rifle with well over 100 million units produced. It became popular with many military powers, but also quickly became a favorite with hunters and sportsman. The design is truly remarkable, as it is extremely rugged, ultra-reliable and can be exposed to extreme elements, and just keeps working. It offers top shooter protection ratings in the event of a catastrophic failure.

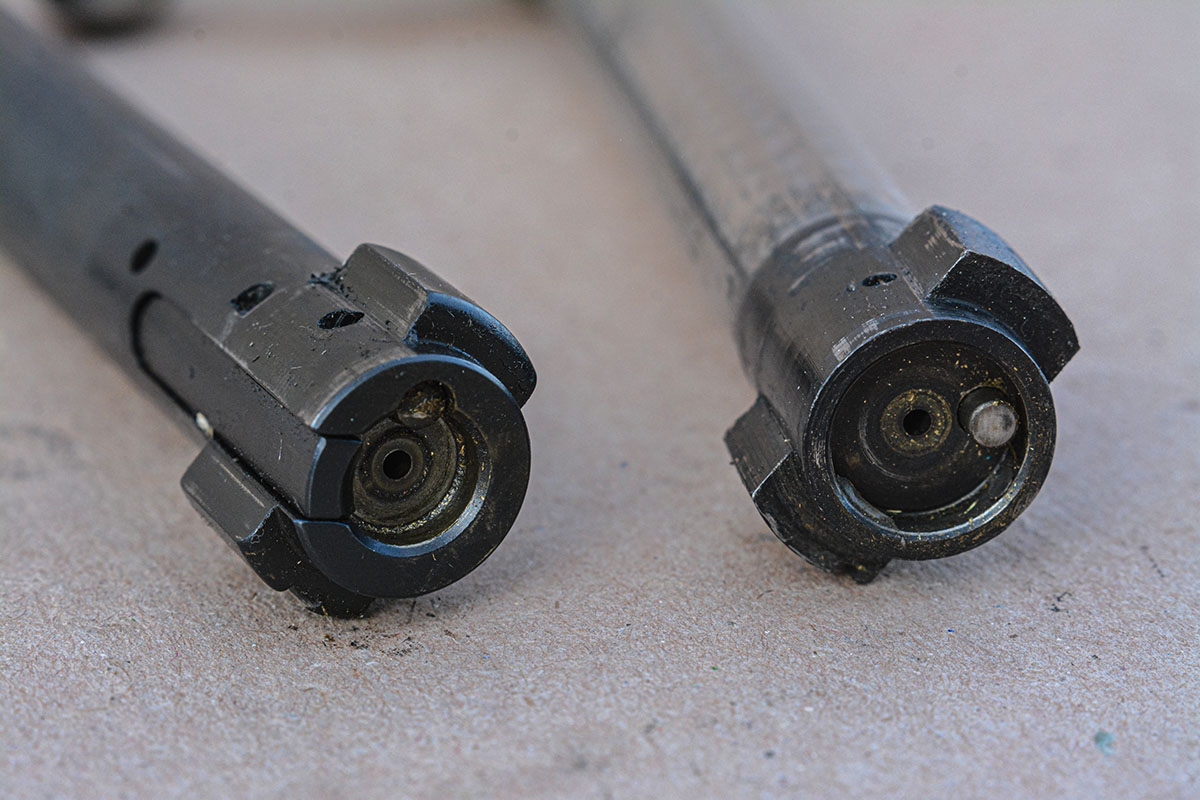

A control feed bolt (top) will literally hold the cartridge and takes control of it once it is stripped from the magazine. A push feed action (bottom) will push the cartridge into the chamber and once it is fully chambered, the extractor will snap over the case rim. Both bolt examples are Model 70 Winchesters.

The Mauser 98 features a large, non-rotating claw extractor with fixed-blade ejector for control round feeding. Its camming power is remarkable, as that strong massive solid-steel claw extractor will pull severely stuck cases from the chamber without issue, or literally rip the rim off. One common

The push feed post-’64 Winchester Model 70 bolt (left) features a rotating extractor, plunger ejector and countersunk bolt face, while the control feed pre-’64 Model 70 bolt (right) features a large, non-rotating claw style extractor, a flat bolt face and is cutout to accommodate the fixed, blade style ejector.

disadvantage with most military actions is that the front of the extractor is not beveled, which means that cartridges cannot be placed directly into the chamber and the bolt closed. Instead, cartridges must first be placed in the magazine and then fed into the chamber by the controlling bolt. However, most commercial M98 actions, such as the FN, will allow cartridges to be placed directly into the chamber and the bolt closed. If you have ever had the opportunity to fire a quality M98 extensively, they are magnificent.

The Mauser 98 set a worldwide standard for other rifles to be judged and it influenced many other military and sporting rifle designs. Naturally, when the U.S. military began to modernize their rifles and cartridges, they ultimately created the 1903 Springfield, which also featured a claw extractor and control round feeding, but in technical terms its design fell short when compared to the M98, with that discussion left for another day. Nonetheless, it became a popular action for custom gunsmiths to build rifles that were popular with hunters and sportsman. When major U.S. gun companies began designing production bolt action sporting rifles, they too designed control round feed actions. Examples include the Remington 30, 30S and 720, which were all basically sporterized versions of the Enfield M1917 action, with production beginning in 1920 and concluding during World War II. Savage introduced a tidy control round feed bolt action in 1920 known as the Model 1920. In 1925 Winchester began offering the Model 54, which was its own design, but still featured the famous claw extractor and control round feeding. The M54 needed several notable improvements that were corrected when it evolved into the legendary Model 70 in 1935.

Note how the control round feed bolt literally holds the cartridge while the push feed bolt cannot.

The Great Depression started in 1929, making the 1930s a very difficult time financially for gun manufacturers. When World War II broke out most firearm manufacturers turned the majority (if not all) of their production capacity to help with the war efforts. After the war, manufacturers

This Winchester post-’64 Model 70 strips the cartridge from the magazine and is uncontrolled until the cartridge is fully chambered.

again turned their focus to producing sporting guns, but many companies had used tooling for other production, moved it, wore it out, etc. Retooling became necessary and this brought on significant changes for most companies.

For example, in spite of Remington using tooling from the Enfield M1917 (and even using surplus actions) to produce their sporting bolt rifles prior to the war, they were still losing money on every rifle!

Beginning in 1944, Remington began working on a new bolt action rifle that would employ a totally new design and new manufacturing techniques that the factory referred to as “reconversion and modernization program.” In a nutshell, production of the Models 721, 722 and 725 began in 1948, but they were discontinued in 1962 and replaced with the Model 700 in 1962/63 with the same basic action but with minor upgraded features. These guns were literally designed to be produced at a modest price. For example, the receivers were round after starting life as round bar stock and required considerably less machining than any previous Remington bolt rifle, or any competing rifle of that era. The rotating extractor and plunger ejector were mounted inside the bolt face resulting in a push feed action, and these parts were small and inexpensive to manufacture and install. While Remington’s initial tooling was costly, the new rifles could be produced at a fraction of the cost of their previous bolt rifles so they became very profitable.

The Winchester pre-’64 Model 70 features positive control round feeding. Note how the bolt face has control, or a hold, on the cartridge.

Savage soon followed with their Model 110 in 1958 and featured a round receiver with push feed system, as well as other changes that served to keep manufacturing costs in check.

The Winchester Model 70 had been a huge success from the very beginning. It was considered a top-drawer rifle by all standards; however, it required considerable machining and labor costs were rapidly increasing. Sales remained strong, but profits steadily declined. Winchester could not raise the price and still compete with the Remington 700 and Savage 110. Several sources report that by around 1960 Winchester was literally losing money on every rifle it built. Changes had to be made. Beginning in 1964 with a receiver that boasted of the same profile (although it used new manufacturing technology and was forged). The action became a push feed design with rotating extractor and plunger ejector, while the barrel became hammer forged. Like the Model 700, the new Model 70 reduced costs considerably. Although the new rifle was sharply criticized by period gun writers including Elmer Keith and Jack O’Connor, it still sold very well.

However, the Model 70 story does not end there. Due to demand from shooters and hunters, as well as new manufacturing methods that helped keep costs down, Winchester again offered the Model 70 “Classic” in 1992 that features control round feed and remains in production today (but unfortunately is now produced in Portugal).

It should be noted that when Roy Weatherby first began building rifles he used 1903 Springfield, Winchester Model 70 and Mauser 98 actions; however, when he designed the big Mark V action with production beginning in 1957, it was a push feed design. In 1971 when he worked with Howa to build the Vanguard rifle (the same rifle as the now popular Howa 1500) it too was a push feed design.

The popular Weatherby Mark V features a robust rotating extractor for a push feed system.

Many high performing rifles feature push feed actions such as the (1) Nosler Custom 48, (2) Allterra Arms and (3) Weatherby Mark V Backcountry.

In 1968, Bill Ruger introduced the M77 bolt action that has become hugely popular. It was a bit unique as it featured a Mauser 98 style claw style extractor with beveling, but has a plunger ejector mounted in the bolt face for a push feed system. However, in 1991, a significant redesign was developed as the M77 Mark II that featured a non-rotating claw extractor and blade ejector and for the first time became a true control round feed system. Today, that action remains more or less the same with the Hawkeye rifle. While we are discussing Ruger bolt rifles, the modestly priced American is a push feed system.

From the late 1950s through 1972, Browning Arms imported their High Power rifle that was based on a Belgium FN commercial Mauser 98 action, which was a top-of-the-line rifle. However, like the pre-’64 Model 70, it too became expensive to produce and a push feed version, known as the FN Supreme, appeared in the late 1960’s until production ceased around 1974. (Note: Browning also imported a Sako built rifle during the High Power series with a push feed action.) Browning next began importing various push feed rifles (mostly manufactured by Miroku) including the BBR, A-Bolt and X-Bolt.

Remington was a pioneer in cutting manufacturing costs after World War II and designed a modern push feed bolt action rifle that was less costly to produce. Examples include the Model 725 (left) and Model 700 (middle and right).

A relatively new comer to the bolt action market is Kimber with its Model 84M and Model 84L, which has a very lightweight, tidy action based on the Mauser 98, with claw style extractor and blade ejector for control round feeding.

Another noteworthy company is Mossberg with their MVP series and Patriot models that are both push feed systems and boast of modest prices.

As noted above, some major companies such as Ruger, Winchester, Kimber and others have reversed trends by offering control round feed actions. However, we have also seen some high end rifles that are heavily focused on accuracy that have elected to use push feed actions. These include Weatherby, Nosler, Gunwerks, Christensen Arms, Allterra Arms, Seekins Precision and others.

It’s important to state that both control round feed and push feed actions can be both reliable and unreliable - depending on the design and quality of a given rifle, but space will not allow a breakdown of specific designs here.

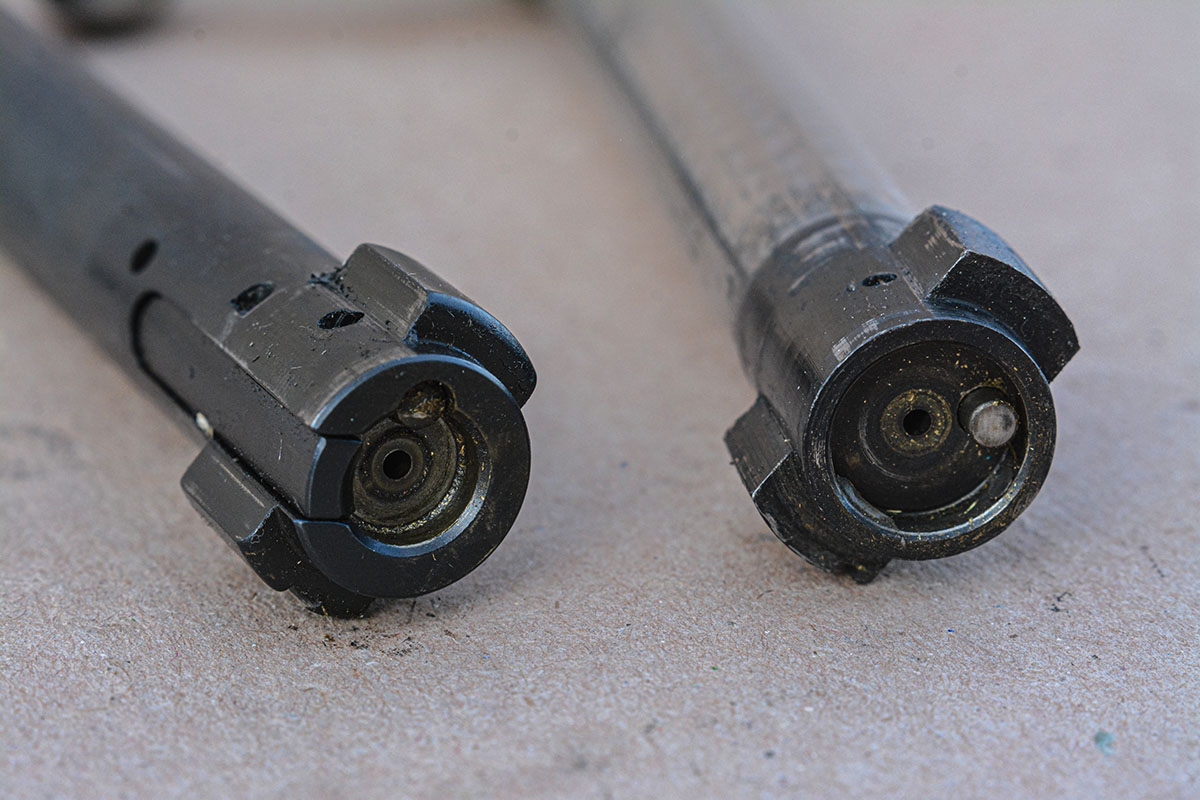

Not all rotating extractors are durable or highly reliable. A Howa 1500 (left) with a strong, external bolt-mounted rotating extractor, is a design that is similar to AR pattern rifles and has proven strong and durable. A Remington Model 700 (right) features a small inside-the-bolt C-clip extractor.

Regarding push feed actions, the differences in how strong and durable various extractors are varies considerably. In other words, they are not all created equal. I tend to favor what is commonly known as the Sako style - it is located on the outside of the bolt body and offers notably greater camming power than most other types, such as the small hook type or the tiny C-clip style that is located inside the countersunk bolt face. If a case sticks in the chamber due to an overload, a split case, etc., it will cam (or pull) harder than most other designs. I have developed considerable load data for ammunition companies, Wolfe Publishing’s

LoadData.com,

Handloader magazine, etc. Some of this data is not mine; rather I was only doing the testing of specified loads, some of which were excess in pressure. Many different rifles have been included. When loads are kept within SAAMI pressure guidelines, most rifles function with reasonable reliability. However, if a cartridge is even modestly overpressure, which happens even with factory loads, the weak extractors quickly become apparent by leaving a case in the chamber, or breaking. I have broken and repaired many rifles with rotating extractors that are of poor design, but it is rare to have the Sako style break or wear out. Rifles that feature the outside mounted extractor include the Weatherby Mark V, Vanguard, Nosler 48, Howa 1500, Smith & Wesson 1500 and many others. Incidentally, I have never had an extractor break on any of the above-mentioned rifles. As a side note, the AR-15 pattern rifle features an extractor that is similar to the Sako style. These rifles are often fired in high volume by both military and civilians until the barrels become severely hot (jumping pressures) and are used under harsh conditions, but the extractors remain largely trouble free.

Push feed actions vary significantly in design and reliability: (1) Winchester Model 70, (2) Remington 700, (3) Howa 1500, (4) Savage 110, (5) Ruger 77R and (6) Weatherby Mark V.

The Winchester post-’64 Model 70 Classic rifles were introduced in 1992 with control round feeding similar to the pre-’64 version, which have become widely popular.

One problem that has occurred with various push feed actions is that the cartridge somewhat “jumps” out of the action as the bolt is closing. This is not necessarily a follower or follower spring tension problem. For example, I have two push feed rifles chambered in 6.5-284 Norma that has an industry maximum overall cartridge length of 3.228 inch. This cartridge is too long for 308 Winchester actions and on the short side for 30-06 (3.340 inch) length actions; however, both rifles are chambered in the latter action length. When sitting down calling

Many modern rifles feature a push feed action. Just a few examples include: (1) Ruger American, (2) Savage Model 10, (3) Mossberg Patriot, (4) Howa 1500, (5) Weatherby Mark V and (6) Remington Model 700.

coyotes and with the muzzle angled up at about 45 degrees, both guns kick cartridges out of the action and into the snow when slowly chambering (in an effort to be quiet). A control feed action will not do that. Another problem that occurs with some belted magnum cartridges of larger caliber with heavy bullets, such as the 375 H&H Magnum and 458 Winchester Magnum, is that the cartridge head is kicked up too high when it leaves the magazine and the bolt is trying to “push” the cartridge home. When this occurs, the case head binds between the closing bolt face and the receiver, resulting in a jam. This does not happen with a control feed action.

The primary reasons that the push feed action remains popular is that they are much less costly to produce, are usually lighter weight, often feature fast lock times and many shooters in the U.S. don’t really care if they have a push feed or a control feed rifle, as they don’t hunt dangerous game. Current trends are towards rifles that offer super accuracy (which has been a huge trend with modern turn bolt rifles the past couple of decades) and are offered at a moderate cost. With the above criteria, push feed rifles have a huge advantage.

As indicated, a quality control round feed rifle will cost more than a rifle of comparable quality with push feed design, with many modern shooters being price point driven. With that said, the advantages of the control action include ultra-reliable extraction when a load (for various reasons) sticks a case in the chamber. The option to pull a cartridge back and eject it at will is also significant, especially for a dangerous game rifle. Many handloaders like the fact that they can literally pull the bolt back to a point and then take their brass out, rather than having it automatically thrown into the brush. I know many professional hunters that will never consider a push feed rifle, rather they will only use high quality control feed rifles. This preference is based on experience in the field when various things can go wrong. If a rifle fails due to operator error or mechanical error, it might cost lives.

Incidentally, I was thumbing through my files on countless thousands and thousands of test rounds fired in bolt rifles. There were no failures to feed, fire and extract with many commercial and military rifles such as the Mauser 98/98K, Winchester pre-’64 Model 70, Kimber of Oregon BGR, Kimber 84M/84L, Ruger 77 MK II, CZ 550 or 527 and other traditional control round feed rifles of good quality.

A good rifle is a good rifle. Both feeding systems can be rugged and very reliable. As indicated, I use both action types and respect each for their individual strengths. However, I try to select the best design for a given task.