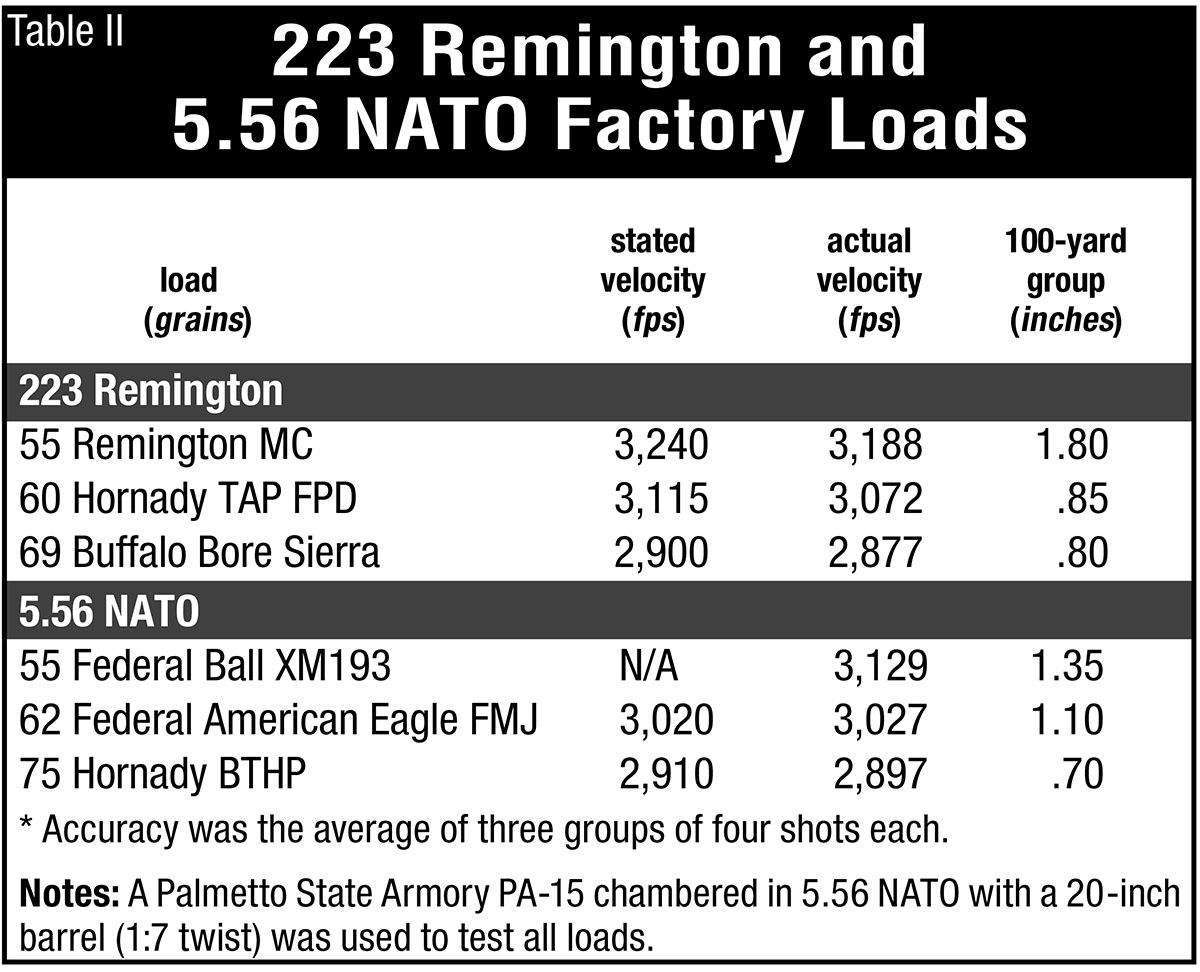

Brian tried the Palmetto State Armory PA-15 with factory loaded 223 Remington and 5.56 NATO loads and handloaded ammunition.

Palmetto State Armory (PSA) firearms are manufactured in Columbia, South Carolina, and PSA employs more than 200 people.

Few rifles have become so hugely popular, developed such a loyal following and have been so controversial (more on that in a moment) as the AR-15-pattern rifles, which is the

Palmetto PA-15 MULTI lower receiver marking.

semiauto civilian version of the select fire military M16 and is often referred to as a Modern Sporting Rifle or MSR. In the U.S. alone, there are more than 100 manufacturers of AR-15 rifles. Trying to estimate how many have been produced and sold in the U.S. is virtually impossible. However, it appears to be in excess of 24 million, while the M16 production figures are probably close to 10 million. With current world unrest, match competitions and many other factors, it doesn’t look like the demand will subside anytime soon. Today, I want to take a look at Palmetto State Armory, which is a very fast-growing young company that is producing quality AR-15-pattern rifles at modest prices. But first, I want to briefly cover the roots of the AR-15/M16 rifles and the 223 Remington and 5.56 NATO cartridges.

The development of the AR rifle is truly a page of U.S. history, but suffice to say that it was developed primarily by Eugene Stoner and James Sullivan (the latter becoming a Ruger engineer) and was something of a scaled-down version of the previously developed AR-10. The AR-15 was formally announced at Fort Benning in May 1957, and chambered in a new .22-caliber cartridge (222 Special) that had been designed specifically for that rifle. This was all in an effort to meet criteria set forth by the U.S. Continental Army Command of the United States Army. However, some military brass were not yet ready to change from the .30-caliber M14 to a .22-caliber rifle.

The Picatinny rail accommodates many accessories, including reflex sights and scope mounting.

When the Vietnam War broke out, the advantage of a lighter rifle and ammunition became apparent. During 1962 and 1963, the U.S. military conducted extensive tests that impressed forward-thinking military brass as the rifle had fewer failures than the M14 and the hit-to-shot ratio was higher among soldiers. Furthermore, the rifle could be manufactured from stamped parts and was essentially inexpensive and easy to work on. In 1963, the U.S. Special Forces adopted the AR-15 as its standard rifle, and likewise, the U.S. Army

Airborne and others adopted it. This led to an investigation being ordered by then Secretary of the Army, Cyrus Vance, as to why the Army had previously rejected the AR-15. Ultimately, it was revealed that the previous tests had been rigged! (I’m sure that is the first time that has ever happened!) In 1963, Secretary of Defense, Robert McNamara, proclaimed the AR-15 to be the superior weapon to the M14 and ordered production of the latter to be stopped.

P&S rail covers were installed to increase comfort.

While space limitations will not allow a detailed discussion of the final development of the 223, suffice it to say that the 222 Special was renamed to 223 Remington in 1959 (as they were a big part of the project) and was to help differentiate it from other .22-caliber cartridges that were in development at the time and were being considered for military adoption. Ultimately, the 222 Remington case length was increased from 1.700 to 1.760 inches, the shoulder moved forward for greater powder capacity, the neck shortened and the overall cartridge length was established at 2.260 inches. This permitted it to reach 3,250 feet per second (fps) using 55-grain bullets. The 223 was officially adopted as a U.S. service cartridge in February 1964, and became known as “Cartridge, 5.56mm ball, M193.” Initially, it was loaded with Remington bullets and DuPont IMR-4475 powder for a muzzle velocity of 3,250 fps and a chamber pressure of 52,000 CUP. Remington announced it as a sporting, commercial cartridge just weeks prior to its official military adoption.

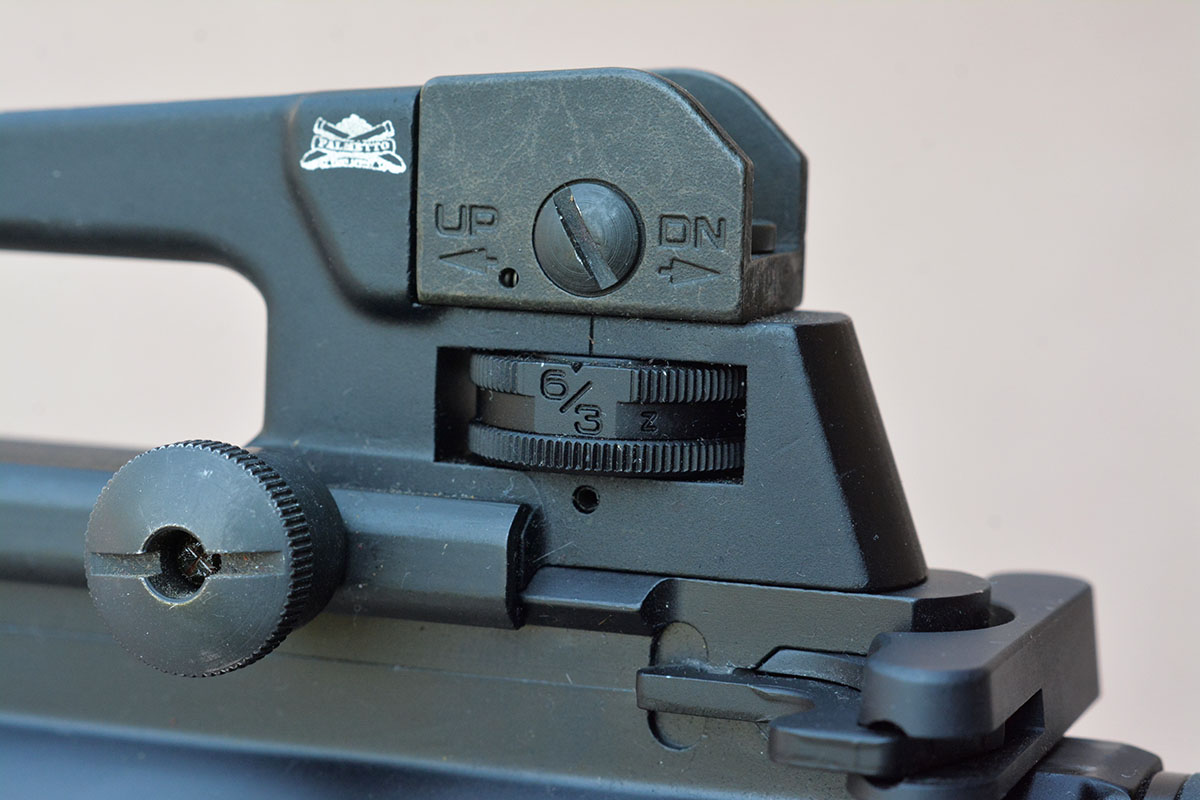

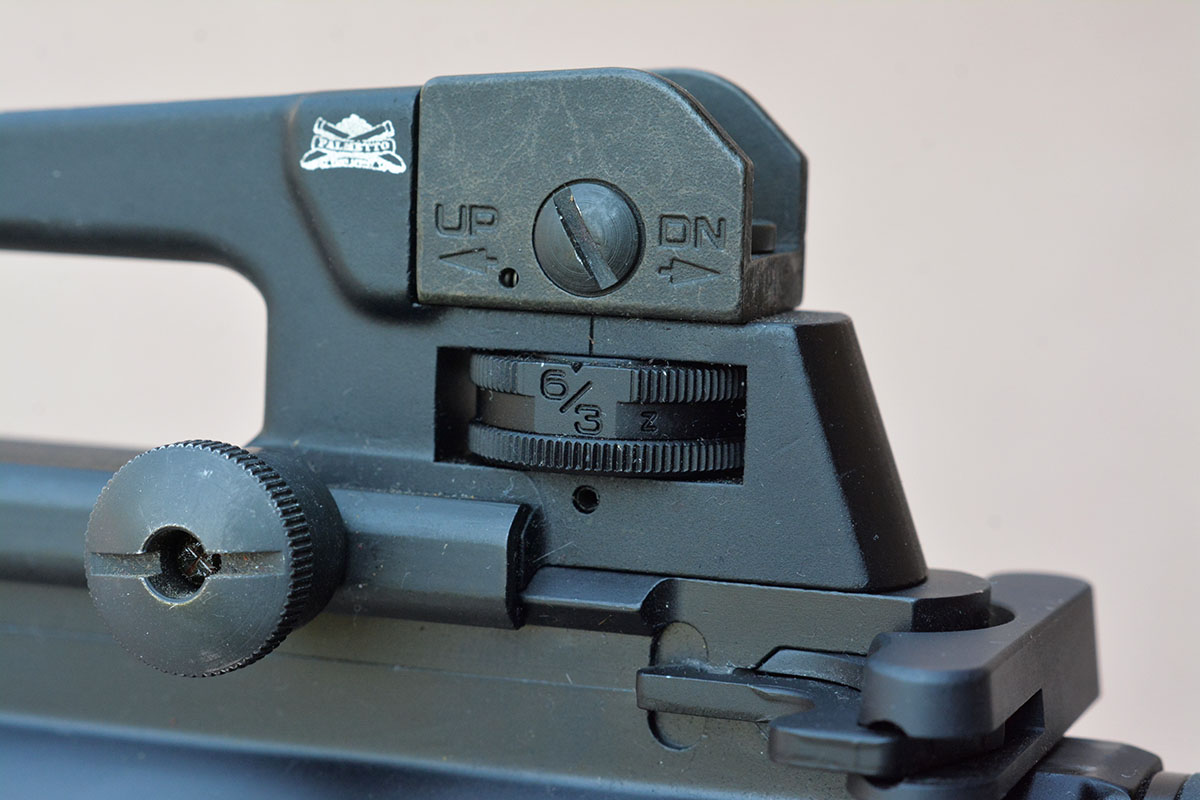

The PA-15 has standard mil-spec features, including a folding rear sight with two aperture hole sizes.

Incidentally, in late 1959, Colt obtained manufacturing and marketing rights to the M16/AR-15 rifle and obtained military contracts, but soon began offering the rifle to the civilian market. It should be noted that the military recommended changes to the design and included a “manual bolt closure” or what we refer to today as “forward assist” and the charging handle was relocated to the rear of the receiver, along with other improvements. It has been stated many times that the M16 features an impingement gas system, however, that is not correct, as it is technically a gas redirect system. The stock is a straight-line recoil design, which results in very little muzzle rise and helps control rapid fire (even full-auto) bursts. The action spring assembly (aka recoil spring or buffer

The PA-15 features a mil-spec forward assist.

spring) inside the stock also serves as a recoil buffer. The rotating bolt head features seven locking lugs, plus a locking lug on the Sako-style extractor that serves primarily to increase extraction support. The M16 has become the longest continuously-serving rifle in U.S. military history and has a better service record than most shooters realize.

I don’t want to get into too much military history and the events that led up to the development of the 5.56 NATO cartridge, but suffice to say that the 5.56 NATO was formally adopted by many NATO countries in 1979 and 1980 and is based on the 223 case. While there are very minor technical differences, the most important items include that the 5.56 is mated to heavier bullets (typically 62-grain M855 to the 77-grain Mk 262) and is fitted with faster twist 1:7 barrels for proper stabilization, although many civilian rifles have been observed with 1:8 and 1:9 twists. By comparison, early AR-15/M16 rifles had a four-lands/groove, 1:14 right-hand twist barrel, but it did not offer proper stabilization at longer ranges and was soon changed to a 1:12 twist with six-lands/grooves. In spite of having a .010 shorter overall cartridge length, the 5.56 has a longer chamber throat. Finally, the 5.56 is loaded to a maximum average pressure of 62,366 pounds per square inch (psi), whereas the 223 is loaded with a maximum average pressure of 52,000 CUP or

The front sight is traditional mil-spec.

55,000 psi. The industry specification of where the pressure is recorded on the case (within the pressure barrel) is different between the two cartridges. The 7,366 psi difference is not even a precisely accurate difference. The bottom line is that 223 cartridges can be fired in a rifle chambered for 5.56, but firing 5.56 cartridges from a gun chambered in 223 can result in excess pressures and is potentially dangerous.

As indicated, the AR-15-pattern rifles have become hugely popular among target shooters, hunters, recreationalists and those wanting to protect property. While it is primarily used for sporting purposes, as a reminder, the grand old Second Amendment had nothing to do with hunting or sporting applications. Rather, it is to protect “We the People” from a tyrannical government! That is exactly why the AR-15 rifles are so controversial! It certainly seems that anti-Second Amendment advocates and politicians who do not understand that simple concept have ulterior motives and clearly exposes their desires to disarm this nation. Nonetheless, every honest, freedom-loving citizen should exercise their right to possess such formidable arms.

This brings us to Palmetto State Armory (PSA), which is a relatively young company enjoying extremely fast growth. The company was founded in 2008, and is located in Columbia, South Carolina, which is known as the “Palmetto State” and thus its name. Currently, PSA employs more than 200 people and has already acquired other companies, including Harrington & Richardson and DPMS. Their incredible growth has not been from lucrative government contracts; rather, success has come from offering quality firearms at competitive prices to ordinary citizens.

The PSA PA-15 features an A2-style detachable carry handle with rear sight.

PSA offers many AR-15-pattern guns in a huge variety of configurations, but all are built to mil-spec or beyond. In essence, the stock style, barrel length and special features can probably be found as standard offerings in a given model. For today’s purposes, I chose a PA-15 with a 20-inch barrel with an outside diameter (at the muzzle) of .735 inch. It features a detachable carry handle with a two-position aperture sight. Naturally, it comes with Picatinny rail to accommodate sight and accessory mounting options. I also chose the fixed stock, which are generally the most stable for accuracy work.

The rear sight is mil-spec adjustable.

This rifle also features an FN (Fabrique National) barrel that features a blend of hammer-forged chrome molly vanadium steel that is often referred to as “machine gun steel.” Basically, the steel is work-hardened and more durable. In addition to hammer-forged barrels offering a notably long life, they feature a chrome process that is nearly twice as thick as a standard M16 barrel, which serves to further increase barrel life. It is chambered in 5.56 NATO with a 1:7 twist and is mil-spec phosphate coated.

It is noteworthy that 1:7 twist barrels can give problems with bullets weighing 55 grains or lighter, especially frangible varmint bullets. The bullets’ revolutions per minute (rpm) often exceed 330,000 rpm. This high-rotational speed can result in lightly-constructed bullets coming apart during flight. The Nosler 55-grain Ballistic Tip was tried and worked fine. However, I elected to change to the Nosler 60-grain Ballistic Tip, which gave better accuracy and corresponded better with the fast-twist barrel. Generally, bullets weighing from 60 to 80 grains are best in barrels with a 1:7 twist.

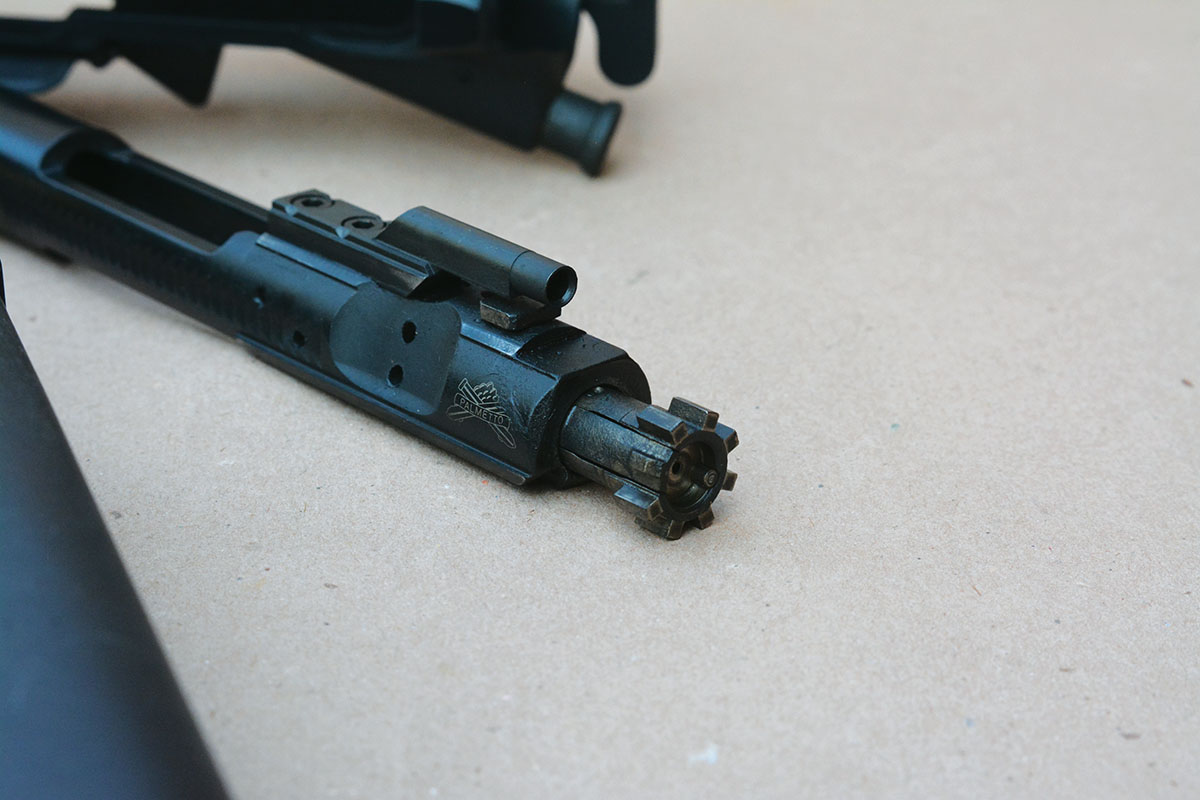

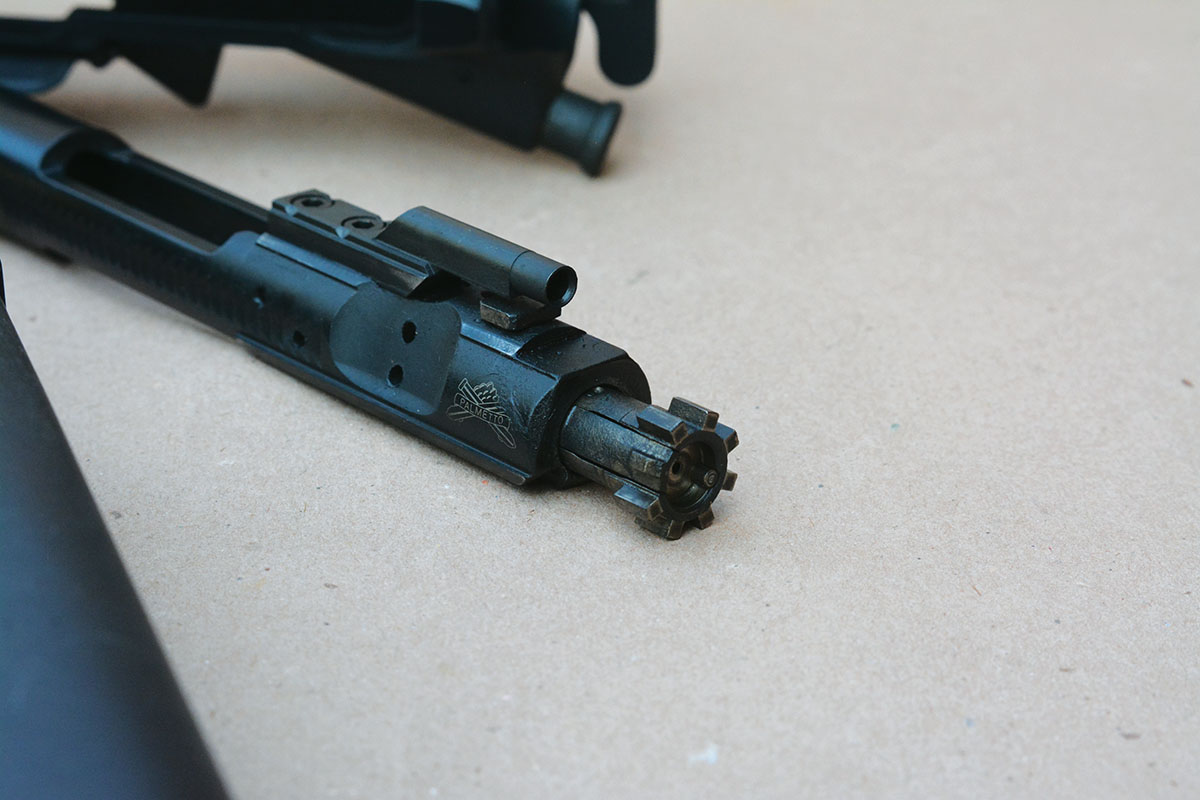

The bolt is a PSA premium bolt carrier group with nickel-boron coating for increased overall performance.

The test rifle was upgraded with PSA’s premium bolt carrier group with a nickel boron coating, which is a feature that is generally only found on rifles with a much higher price tag.

The lower receiver is well made and is built with mil-spec tolerances.

A set of P&S rail covers were installed on the forearm rails. While these definitely make things easier on the shooter’s hands during long sessions, they also protect sandbags.

While Palmetto State Armory offers a huge variety of AR-15-pattern rifles, the sample rifle features a 20-inch barrel, A2-style detachable carry handle with rear sight and fixed stock.

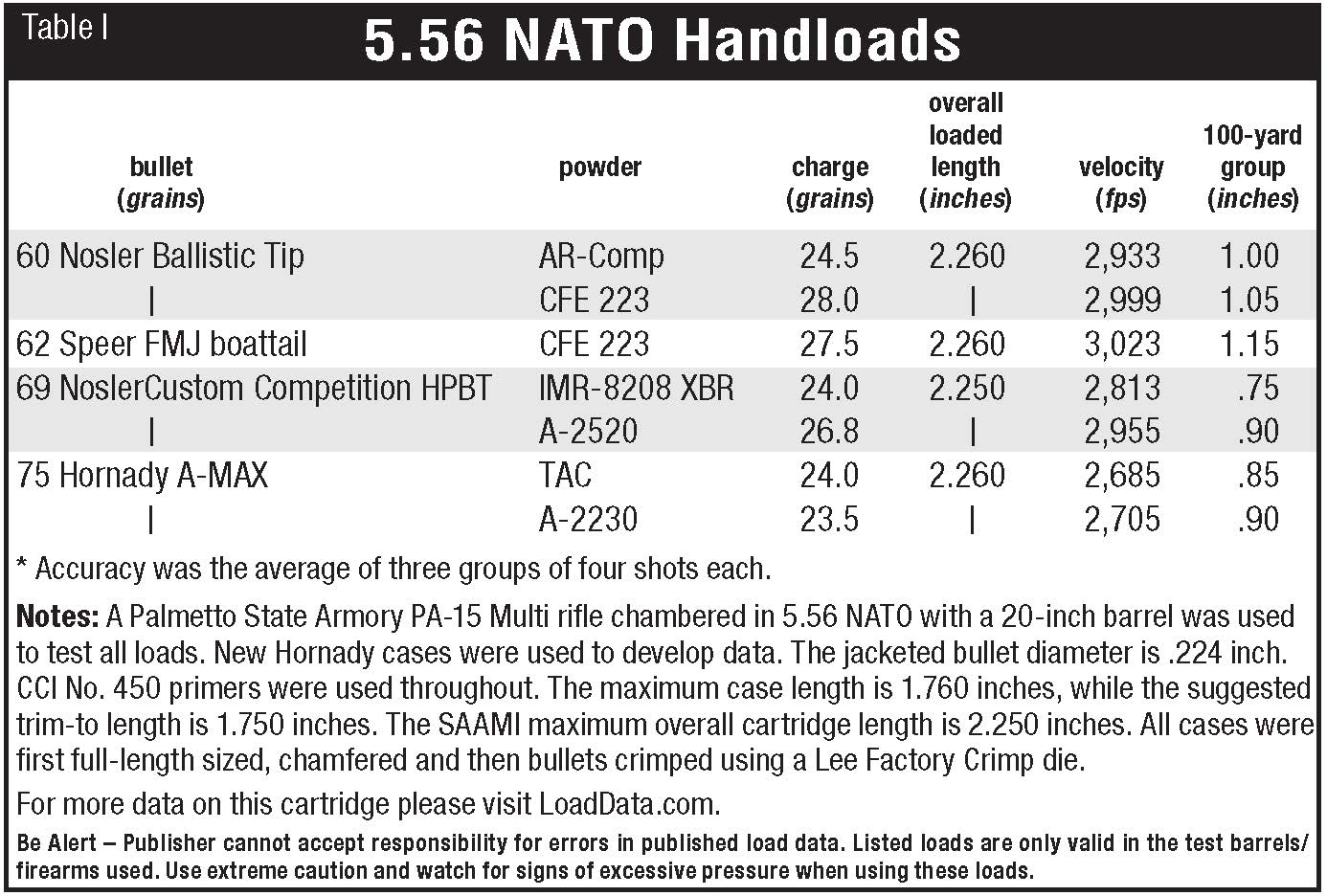

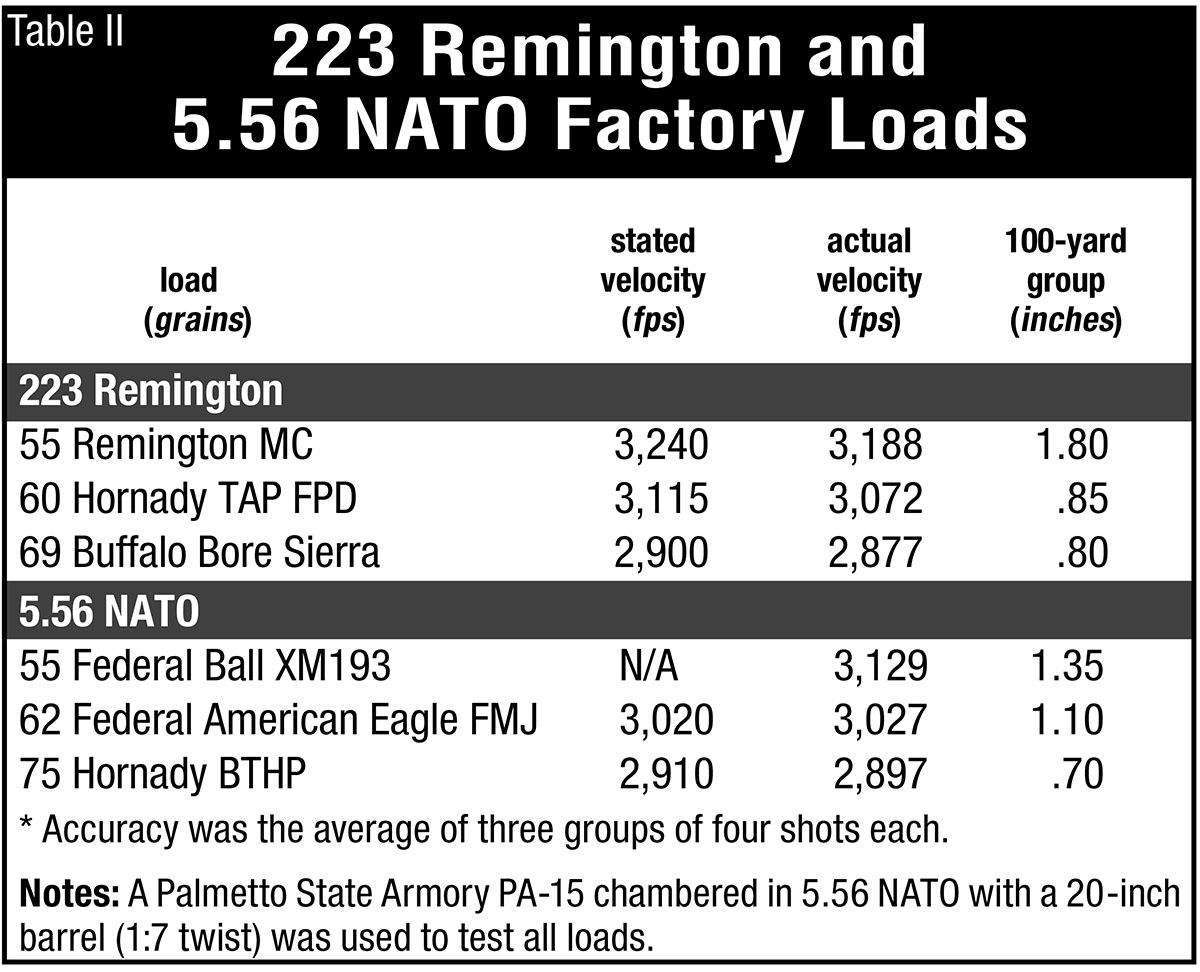

I elected to do all accuracy work with the factory aperture sights. If mated to a proper target, accuracy can be very good with an aperture sight. As can be seen in the accompanying tables, sub-MOA groups were common.

The PSA PA-15 gave excellent accuracy with Brian’s handloaded ammunition containing the Nosler 60-grain Nosler Ballistic Tip bullet.

Six factory loads were tried, including both 223 Remington and 5.56 NATO loads. Loads containing bullets of 60 grains or heavier gave the best accuracy. Using loads from Hornady, Federal and Buffalo Bore with bullets weighing 60-, 62-, 69- and 75-grain weights and firing three groups with each load (four shots each) the average group size was just .8625 inch. The Hornady 75-grain BTHP 5.56 NATO load grouped into just .70 inch.

The Palmetto State Armory PA-15 features a notably high quality 1:7-inch barrel twist rate.

Moving on to handloads, all data was assembled in new Hornady cases and capped with a CCI No. 450 primer. Powders that are known for offering good performance were selected, including Hodgdon CFE 223, Ramshot Tac, IMR-8208 XBR and Alliant AR-Comp. Bullets included the Nosler 60-grain Ballistic Tip, Speer 62-grain FMJ-Boat Tail, Nosler Custom Competition 69-grain HPBT and the Hornady 75-grain A-MAX. Each load produced sub-MOA or very close to MOA accuracy. All loads combined produced an average group of just .9428 inch. The most accurate handload consisted of the Nosler 69-grain NoslerCustom Competition HPBT pushed to 2,813 fps using 24 grains of IMR-8208 XBR powder that grouped into .75 inch.

The 5.56 NATO and 223 Remington can each be fired in the Palmetto State Armory PA-15. However, they are not fully-interchangeable cartridges.

Palmetto State Armory is currently manufacturing a variety of rifles and pistols including its latest offering, the 9mm Dagger pistol, which is based on the Glock 19 3rd generation series. Their prices are modest, especially considering the quality that they offer. I’m impressed with the PA-15, which ran flawlessly throughout several shooting sessions and has shot nearly 1,000 rounds to date.