Marlin's New 336

Good as the Old? Better?

feature By: Wayne van Zwoll | November, 24

A pair of powerful inboards kept a 7-knot pace from Wrangell, past peaks vaulting from tidal beaches. The forested slopes above shed 18 feet of rainfall annually. At dusk, we dropped anchor near an abandoned fishing village on Prince of Wales Island. The next evening, Mark nosed his skiff up a creek. We moored with a long line, mindful of huge tidal swings.

On game trails, we treaded waist-high grass along the forest’s edge. “Bears!” hissed Mark, pointing. We crawled to close the distance, me up front. Then the breeze swung. Both animals dashed for cover. On my knees, I caught the boar in the 2½X Leupold and fired when he paused. The 170-grain flatnose struck audibly. He vanished in the timber. Big splashes of blood led us to the heart-shot bear.

“I guess I didn’t need this,” Mark said, leaning his 375 against a tree.

The next September, I carried the Marlin into the hills of Utah and at dawn one morning I slipped into a herd of elk. A young bull, quartering on, stopped to test the wind. A slot in the foliage exposed his neck. A 30-30 bullet centered it, felling it instantly.

There was no reason to use a different rifle for deer and pronghorn. A check of the scope’s zero, prone on Wyoming prairie, showed it unchanged. Laying the Marlin on my mat, I walked off to pull the targets. A friend drove up. He saw me but not the 336. His Suburban ground its receiver, lever, wrist and scope into the earth, splitting the buttstock into three pieces. I squeaked out something like: “That’s okay. It’s honest wear.” We taped the wrist and tugged on the lever until it yielded. Bent parts plagued cycling, but the carrier reluctantly fed cartridges. The extractor and ejector functioned. Astonishingly, my first shot at 100 yards hit center. The rifle went hunting and took a mule deer and a pronghorn, at 155 and 160 yards.

His first rifles, in 1875, were based on C.H. Ballard’s single-shot action of 1861. Twenty versions chambered cartridges from 22 rimfire to 45-100. Hunting models fetched $22, Schuetzens $90. A lever-driven under-hammer repeater flopped. A superior design in 1882 became the Model 1881 six years later. In 45-70 and 40-60, this 10-shot lever rifle scaled from 9 to 11 pounds. At $32, it was costly for its day. A small-frame version in 32-40 and 38-55 ensued. The 1881 began military trials brilliantly, firing 10 shots in 7 seconds. Alas, the 48th cartridge exploded in the magazine. The Army demurred.

Doc Carver, Bill Cody and other celebrated riflemen liked Marlin’s ’81, though top ejection sent empties through line of aim and the dust cover didn’t keep dust from the action. Also, cartridges moving from magazine to carrier often jammed. Subsequent Marlins would eject to the side. A split carrier for the 1881, with a wedge to expand it in cycling, eliminated jams.

John Marlin found his own brilliant engineer in Lewis L. Hepburn. In 1871, at age 39, Hepburn had gone to work for Remington, where he developed the Remington-Hepburn No. 3 single-shot rifle. Hired by Marlin in 1886, Hepburn would design its Models 1888, ‘89, ‘91, ‘92, ‘93, ‘94, ‘95 and ’97 rifles. He was badly hurt by a fall on ice in 1910 and never fully recovered, passing in 1914.

Hepburn’s Model 1893 was a hit with deer hunters. Introduced in 32-40 and 38-55 at $13.35, it had the 1889’s side ejection, fine-handling qualities and reliable function, plus a two-piece firing pin and stouter lock-up. Its receiver was stronger than the Winchester 1894 and fully enclosed the action. After a five-year wartime production hiatus, the Model 1893 reappeared in 1922, chambered also in 30-30, 32 Special and 25-36 Marlin. (The 25-35 Winchester could be fired in Marlin 25-36 chambers.)

The Model 336 endured the market onslaughts of bolt rifles during the 1960s and 1970s. It remained Marlin’s flagship, though some versions faded. The 32 Special chambering was dropped in 1968 – three years after the 444 Marlin, developed with Hornady, joined as a big-bore option. Marlin reintroduced the short-action Model 1894, in 44 Magnum, in 1969. The Model 1895 in 45-70 reappeared in 1972.

By this time, production costs of lever-action and bolt-action rifles were on crossing trajectories. In 1963, on the eve of the Model 70 overhaul that brought anguished howls from the faithful, Winchester priced that elegant bolt-action – even in magnum chamberings through 375 H&H – at $154.50. Marlin’s 336 retailed at $86.95. Thirty years later, the Winchester Model 70s started at $423 and Marlin’s 336 cost $319. Savage’s lever-action 99 rifle fetched $620. Within a decade, the 99 would be discontinued. Shortly thereafter, Marlin’s 336 became more expensive than a basic Model 70. The reason – manufacture and assembly of lever rifles begged handwork that couldn’t readily be farmed out to CNC machines. The supply of skilled labor was diminishing and its cost was increasing. Hiking prices to keep lever rifles profitable was bound to put a lid on demand.

In July 2020, Remington filed for its second Chapter 11 bankruptcy in two years. That fall, Judge Clifton R. Jessup Jr., of the Northern District of Alabama, approved the sale of Remington’s non-Marlin firearms business to the Roundhill Group for $13 million. Ruger paid $28.3 million for Marlin.

To reverse the slide in the quality of Marlin rifles during their tenure at Remington, Ruger CEO, Chris Killoy and his staff bent to the task of building Marlin lever-action rifles to original or higher standards of fit, finish and function. One key to profitably: the lean manufacturing methods Ruger had employed in producing fine, but affordable, revolvers and centerfire rifles. Marlin tooling would be moved from Ilion to Ruger’s Mayodan, North Carolina, plant, which was the source of AR-556 and most Ruger American rifles.

Bruce Rozum, whom I knew when he had headed the research and development department at Marlin, had moved to Ruger’s Newport, New Hampshire, facility as chief engineer. He tapped early CAD drawings to develop a hybrid production model for the Mayodan project, holding CNC tolerances of .002 on a rifle 125 years old.

The first Marlin on the schedule was the 1895 SBL (stainless, big loop). Product Manager Eric Lundgren, who had worked for Remington, told me that, though the Marlin 336 in 30-30 accounted for most sales under that label, the 45-70 was getting lots of press and shooter interest and Ruger’s would be the only stainless lever rifle so chambered.

Refining the infrastructure, processes and design took many hands over months. Thousands of shots in test tunnels followed. “We’d planned to have Marlins in gun shops by the end of 2021,” Ruger’s Mark Gurney told me. The first serialized SBL was boxed on September 30. A sample soon reached me.

Clearly of Marlin heritage, the SBL is hardly a clone of the original 1895. It’s all stainless, with an oversized lever loop, a 19-inch barrel rifled 1-in-20 and threaded 11⁄16x24 at the muzzle. The stock, of gray laminate, has a forend cap with an integral swivel stud. A Picatinny rail extends 7 inches ahead of the receiver, an adjustable HiViz ghost ring sight paired with a green, tritium-ringed HiViz front bead.

Details not on previous Marlins included an “RM” serial number prefix, a fluted, nickeled bolt and a laser-engraved Marlin horse-and-rider logo instead of a grip cap. (John Marlin had asked Frederick Remington for the use of this image from his 1890 painting, “Danger Ahead.” It first appeared on Marlin’s 1900 catalog.)

Across a range of loads, the SBL’s accuracy beat my expectations. At 100 yards, with help from a Meopta 2-10X 42mm scope, 300-grain semi-jacketed hollowpoints averaged just under 1¼ inches. Hornady 325-grain FTXs punched a ¾-inch cloverleaf, with Black Hills Ammunition 325 Honey Badgers grouping almost as tight.

The multitudes awaiting their SBLs were soon swelled by those queuing up for the 336 in 30-30. Waiting was my penalty for not lining up sooner. But at last, the box arrived.

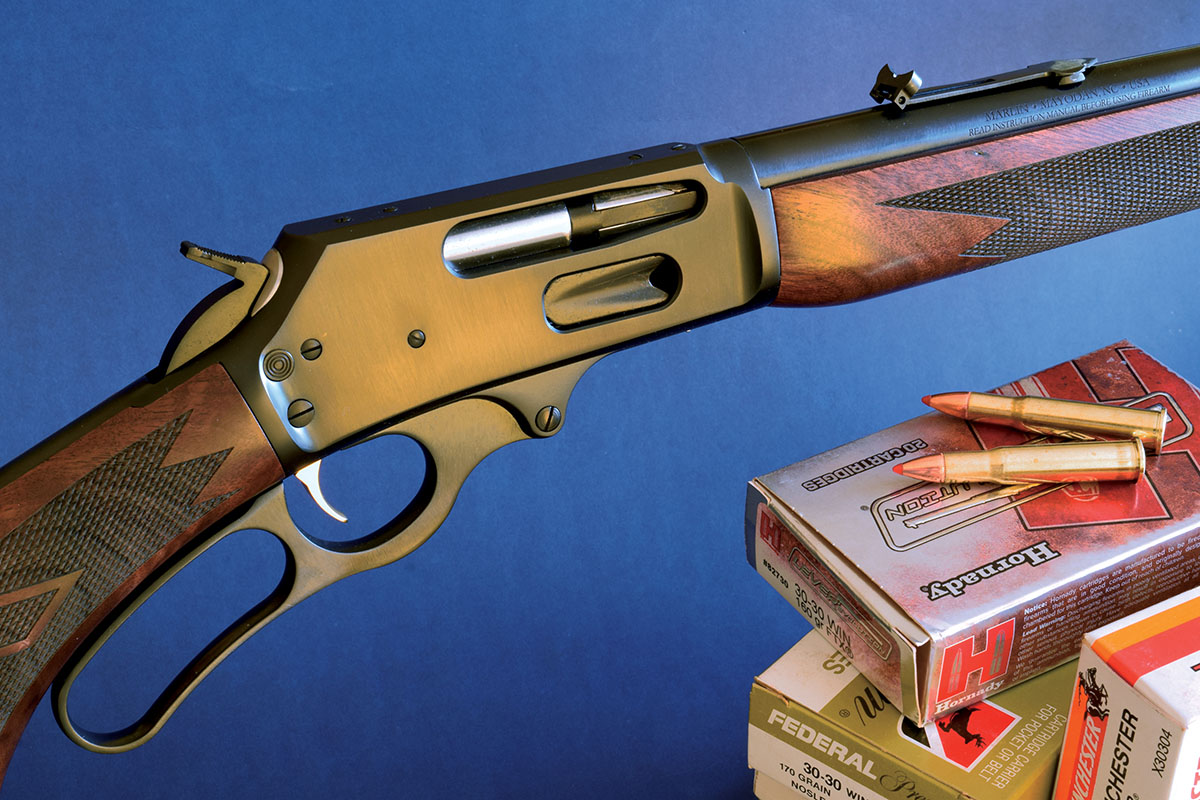

Modeled closely on the original Marlin 336C, the Ruger rendition is faithful in profile. A 20-inch barrel rifled 1-in-12, shadows a full-length six-shot magazine with forestock and muzzle bands. The sights were a folding “U” rear sight and a flat-faced gold bead. The chrome-moly steel’s bluing brings to mind that on late pre-Remington 336s; ditto the gold-plated trigger. Like its predecessors, the new carbine has a pistol-grip stock and slightly flared forend, both well fitted.

Around 1980, I bought a new 336C in 30-30. Last week, I pulled it from the rack for comparisons with the new version. Herewith are some of the differences between Marlins 45 years apart and my take on them.

The receiver on the 1980 Marlin has a higher polish, but the quality of polishing (clean edges and flat flats, especially around the port and screw holes) is a tad better on the new carbine.

The serial number has moved from the tang to the low left side of the receiver. The numbers now are smaller and neatly rendered. A cosmetic plus.

The new carbine’s barrel stamping/engraving, in a crisp but delicate script, is more attractive than the traditional stamping that craters numbers and letters, and there is less of it.

While the folding rear sights and hooded front sights are identical in profile, the new Marlin has a gold bead, lacking on the 1980 sight.

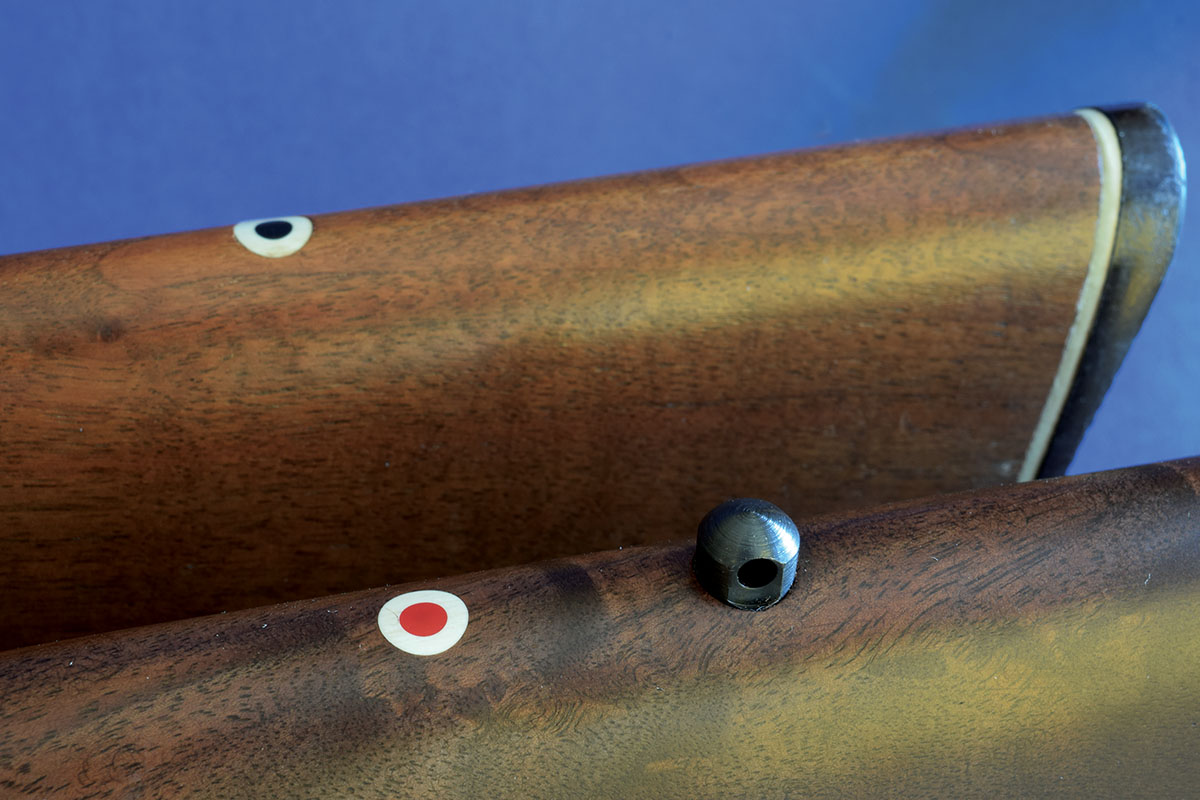

Both carbines are drilled on top for scope mounts. The earlier 336 has two additional holes in the receiver’s upper left corner for traditional aperture sights. Some shooters will mourn their loss.

The grooved hammers of both carbines have the same profile, but at 5⁄16 inch, the new Marlin’s hammer is 1⁄16 wider than the earlier versions. More grip. Bravo!

Like the SBL, the bottom of the pistol grip on the new carbine is laser engraved with the “Danger Ahead” Marlin logo. A welcome change from the black plastic grip cap with white spacer on the old 336.

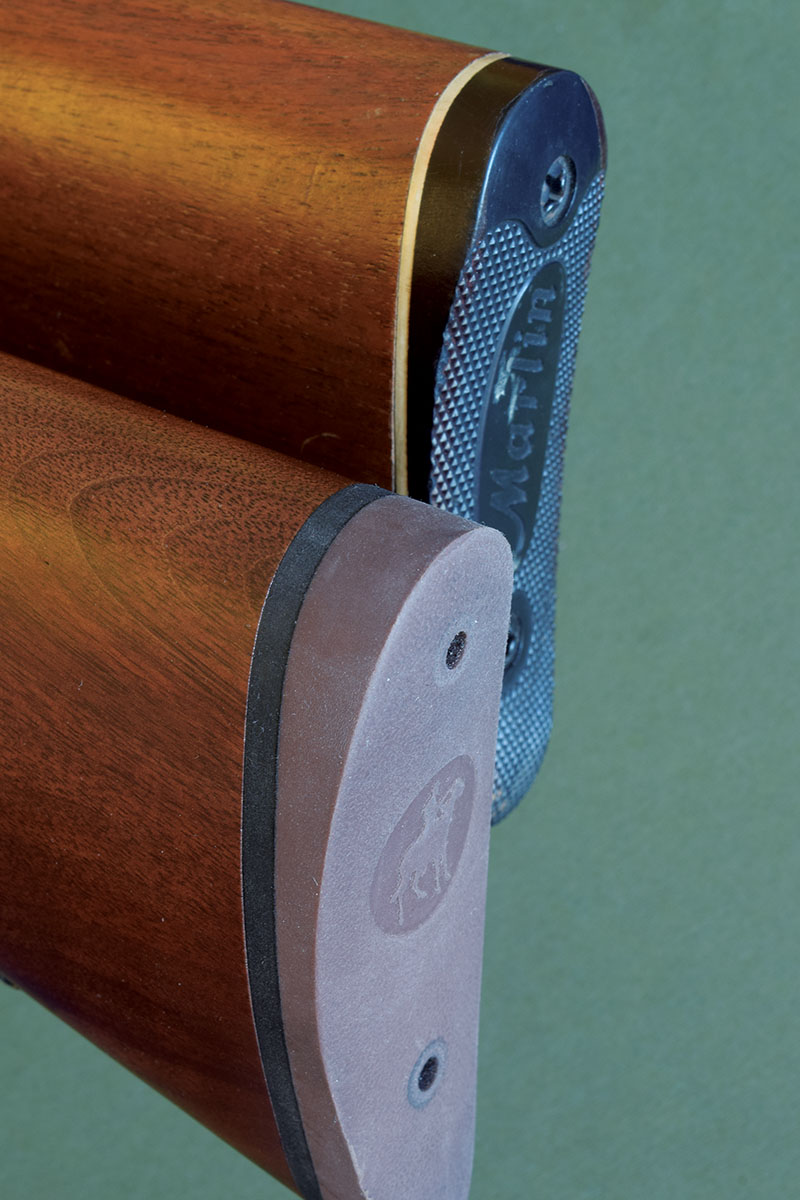

The 1980 carbine’s checkered black plastic buttplate with a white spacer has given way to a thin brown recoil pad with the Marlin logo. I like that change.

Ruger added sling swivel studs at the stock’s toe and forend band. Hooray! My 1980 Marlin has no swivels or studs.

Point-pattern checkering, absent on the earlier 336C, is generous and neatly executed on the new Marlin. It wraps the forend. Diamond-shaped ribbons enhance it. By any standard, it is an upgrade.

The black center of the “Marlin dot” near the stock’s toe is now red, per the red griffin on Ruger’s first 22 handgun, before Bill Ruger changed it to black at the untimely death of Alex Sturm.

While leaving the crossbolt safety off and instead using the half-cock hammer notch is an option on the new 336, my vote goes to the original design, with no safety to get bumped on or off.

Some differences between these 336s are individual, not linked to vintage. The walnut on my new Marlin isn’t fancy, but it has some figure and is darker and richer in color than the wood on the 1980 carbine.

The earlier Marlin’s trigger breaks at 5 pounds, about a pound less than the new 336, which also has a touch of creep. Chalk one up for the original.

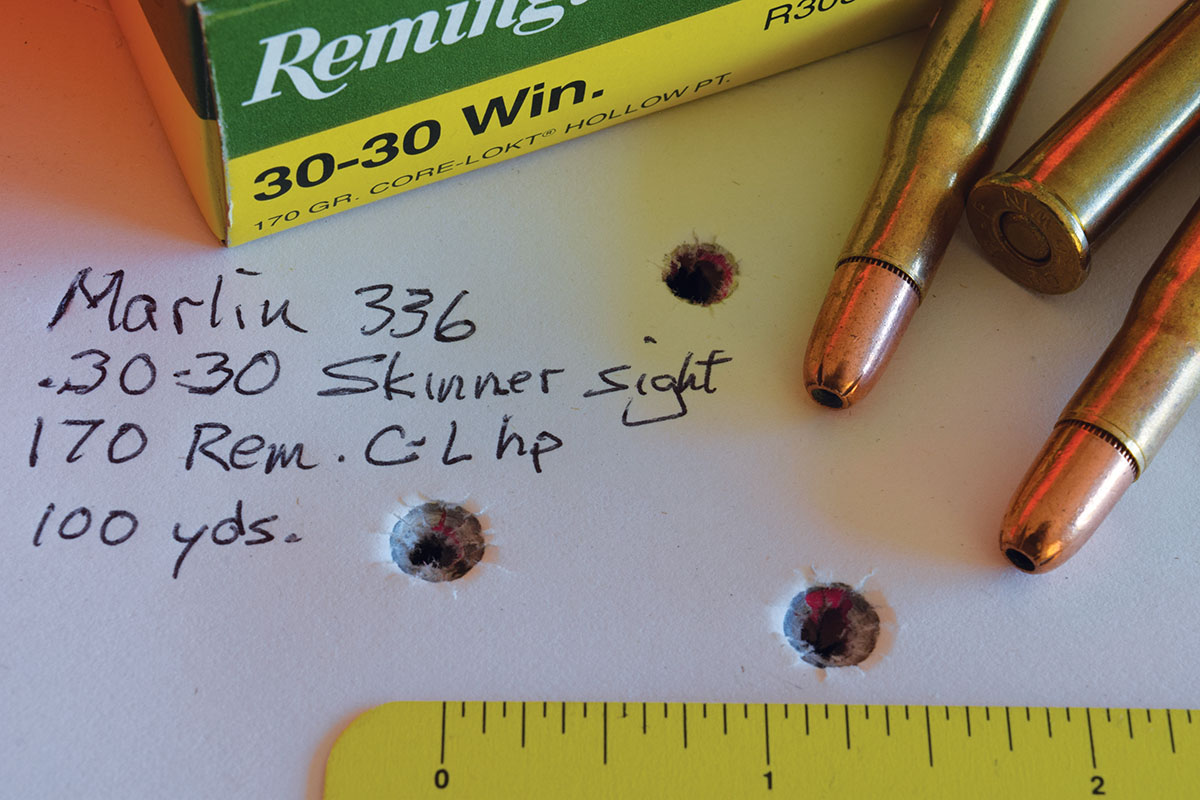

Before range trials, I attached a Skinner aperture to the new 336. With the midsize aperture Andy Larson lists for it, the Skinner is my first pick among current metallic sights. It’s more accurate than open sights and, arguably, faster. It uses factory-drilled scope base holes. The carbine’s comb naturally aligns my eye with it and the big gold bead. A caveat is that you may wish, with the Skinner sight, to install a slightly higher bead up front, to nudge point of impact down.

Sure, a scope brings sharper sight pictures than any metallic sight. But to those of us mired in the past, optics and lever rifles seem an odd pairing. A scope on a saddle gun smacks of roof-rack luggage on a Porsche 911.

Out of the box, the new 336 cycled with only a hint of the stiffness that can plague newly-minted lever-action rifles. But soon, it ran as smooth as a race engine. No rattles, no hitches. Cartridges fed and cases flew out the window reliably. Shooting was fun! Death on deer, the 30-30 is a caress in recoil, compared to the sharp-shouldered rockets serving shooters who consult smartphones to chart bullet paths.

In my view, the 30-30 is a 150-yard cartridge. Hornady’s FTX bullets trace flatter arcs than do traditional softpoints, and often print the tightest groups. But a ton of energy is all you’ll get from even those missiles at the muzzle – about what a stiff 308 hunting load brings to 200 yards. That far out, a 170-grain bluff-nose 30-30 bullet can’t muster 1,000 foot-pounds, less than a 165-grain 308 spitzer has at 500 yards! As important as knockout punch is the ability to land it accurately. My limited talents with lever-action carbines, even scoped, warn me off shots at game much beyond 150.

The new 336 has proven as accurate as many bolt rifles that have come my way. Remington 170-grain Core-Lokt hollowpoints punched groups as tight as 1.4 inches at 100 yards, edging the flatter-flying 160-grain FTXs. Almost certainly, a scope would have snugged those knots. Most dispersion from Federal and Winchester 150- and 170-grain loads was vertical. In fact, horizontal dispersion in three groups was .3, .7 and 1 inch, in groups with vertical spreads of more than 2 inches!

A long-time fan of the 336, I’m delighted with how Ruger brought it back. Just about every tweak is an improvement, noticeably the flat (and hard-to-achieve) receiver polish, crisp stock detailing, fit and finish. It cycles smoothly and reliably and it shoots accurately. It’s a rifle any lever-action enthusiast – heck, anyone who’s ever looked lustfully at a rifle – would be proud to slip in the scabbard or cradle for a walk in the woods. Evidently, the word is already out, as Mayodan’s Marlin cell is straining to keep up with orders. “We’re making as many as we can,” Mark Gurney assured me. “Without compromising quality.”

That caveat makes a new Marlin worth the wait!