Ross Rifles

Exploring Rumors and Realities

feature By: John Barsness | January, 20

Ross ended up in the U.S., where his first factory rifles were built in Connecticut; afterward some were also made in England. In 1897 Ross emigrated to Canada, and around the time of the Boer War of 1899-1902 (where he served as a lieutenant) the Dominion of Canada and Great Britain had a diplomatic spat. As a result, Britain refused to license the manufacture of Lee-Enfield .303s in Canada. In 1903 Ross persuaded Canada to accept his rifle, partly by offering to build a factory in Quebec City.

The Canadian Expeditionary Force used Ross rifles during World War I, and Britain also acquired some due to a shortage of Lee-Enfields. However, the Ross rifles proved unreliable in trench warfare, frequently jamming – and even when they did not jam, the bolt occasionally blew out of the rear of the action, maiming or killing soldiers.

For rifles that appeared relatively briefly and died notoriously, interest in Ross rifles still abounds, as does misinformation. Many shooters who have never read anything on the subject “know” a Ross should never be fired, since the bolts will randomly blow out of the action.

This primarily occurred with the very last model of Ross rifle, which was used extensively in World War I. It was indeed possible to take the bolt apart – say for cleaning during muddy trench warfare – then reassemble it wrong so it never locked yet could still fire. Eventually the problem was diagnosed, and many of the bolts were modified to prevent incorrect reassembly, but no, it was not an inherent and random flaw in all Ross rifles.

Many shooters also believe all Ross rifles were chambered for the .280 Ross, a rimless “magnum” that appeared in 1907 using bullets .287-inch in diameter. The .280 was the first commercial centerfire round to push bullets over 3,000 fps, but early jacketed softpoints did not hold up well to such velocities on big game.

The most famous instance firmly implanted the .280 Ross in hunters’ minds: In 1911 George Grey was chasing lions on horseback in Kenya with several companions. Standard procedure was to ride after a lion until it turned and charged, whereupon the hunter would dismount and shoot the lion, quite sportingly.

Unfortunately, despite Grey using the straight-pull bolt to quickly shoot an oncoming lion twice, first at 20 yards and again at five, the bullets failed to penetrate and the lion mauled Grey so severely he died a few days later. Ross rifles and the .280 Ross cartridge thus became inseparable in the public mind.

I knew some of this history before running across a Ross .303 in 2018 at Capital Sports & Western Wear in Helena, Montana. It was not a pristine “collector” rifle, but what turned out to be a somewhat mysterious mixture, modified after leaving the factory, perhaps more than once.

When discussing Ross rifles, which model designation is used often depends on whether the rifle is a military or sporting version – or the whims of the person doing the discussing. The Canadian military designation of the last version of Ross rifles, known commercially as the Model 1910, was the Mk. III. As a result, Ross enthusiasts often refer to sporting rifles as 1910s and military rifles as Mk. IIIs.

The rifle in Capital Sports appeared to be a “sporterized” military rifle, but the receiver ring is stamped “ROSS RIFLE COMPANY CANADA M-10 PATENTED.”

I had long been interested in the Ross story and a light through the bore showed it to be pretty shiny, so I handed over my credit card.

Upon arriving home, however, some tiny pits showed up in my Gradient Lens borescope. They did not look large enough to affect accuracy, but it took a while to find out, because before firing the rifle I did considerable research on the bolt problem.

Early Ross rifles used a two-lug bolt head but later on featured an interrupted screw bolt head, the kind in my M-10 .303. My rifle was also one of many that had a rivet installed in the bolt body, preventing incorrect reassembly, which occurs when the firing-pin assembly was screwed in too deeply. In a correctly assembled bolt, the bolt head should be about an inch in front of the bolt body. If it ends up right in front of the bolt body, the locking lugs end up behind the locking recesses, and the rifle can still be fired, at least sometimes.

You can confirm whether the bolt head is locking by looking inside the receiver ring as the bolt handle is shoved forward. With a correctly assembled bolt, you can actually see the bolt head turn into the locking lug recesses.

A flashlight helped considerably, but a flashlight-free demonstration appears in one of a series of YouTube videos called “Forgotten Weapons,” hosted by Canadian Ian McCollum, which I eventually ran across while doing Ross research on the Internet.

Surprisingly, the bolt did not leave the action, instead blowing backward until the bolt head encountered the substantial bolt stop, a steel cylinder notched on one side with a lever on the opposite, much like the 1903 Springfield’s. McCollum decided to repeat the experiment but a new cartridge refused to fire – twice. The first time the firing pin never marked the primer and a second attempt only left a very light indent.

Despite knowing my 1910’s riveted bolt was assembled correctly, I initially fired the rifle with its stock firmly wedged in a weighted cardboard box, pulling the trigger with 25 yards of nylon rope. The handload fired safely and ejected easily, so I started shooting at targets.

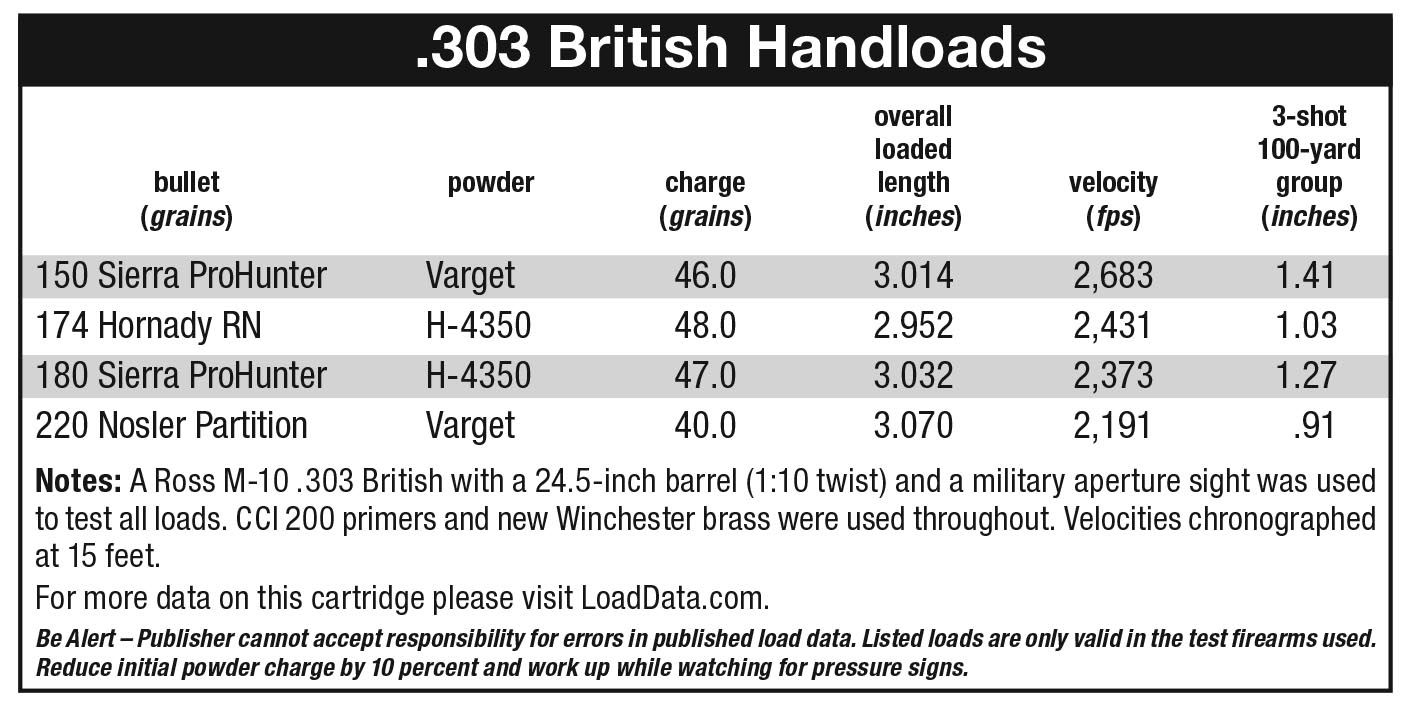

The initial handload was based on a load that had proven accurate in other .303s, including a sporterized WWII-era Lee-Enfield inherited from my Uncle Larry, and one of the Ruger No. 1As offered in .303 several years ago. (“The .303 British: Handloading a Cordite Cartridge with Modern Powders” appeared in Handloader No. 273, August 2011.)

It also shot about 6 inches high when using the fixed, open rear portion of the flip-up rear sight, even with the front sight buried deeply in the “notch” (actually a round aperture with an open top). Such a high point of impact is common among older iron-sighted military rifles, which were often regulated so a middle hold on a standing enemy soldier would result in a hit out to fairly long range.

In fact, one Internet reference, originally published in a print magazine in 1942, states the open sight was regulated for 600 yards, which matches closely with the 25-yard trajectory as calculated on Sierra’s Infinity computer program with the company’s 180-grain ProHunter spitzer. Beyond 600 yards, a soldier was expected to flip the sight up and use the real aperture portion, which could be easily adjusted to very long range.

However, my usual plan for new-to-me rifles is to take them hunting, where such trajectories would not do. Some measuring and calculating indicated the front sight needed to be about .2 inch higher in order for my handload to land near point of aim at 25 yards. I rummaged around in my tackle box full of various “iron” sights, eventually finding a flat-topped post of unknown origin of just about the right height, with a slanted face painted white inside a black border.

The sight’s dovetail was a little larger than the slot on the Ross’s front-sight base, but 10 minutes of work with a triangular file allowed my Williams sight-pusher tool (purchased from Brownells many years ago) to press the new sight firmly into the Ross base. I then loaded some more 174-grain ammunition, one round with 47 grains of H-4350 and the rest with 48 grains. According to the velocity rule for single-based powders (increasing the charge increases muzzle velocity the same percentage), the 48-grain load would get just about 2,440 fps – and did.

The 47-grain load fired normally, so I fired three shots with the 48-grain load at a 25-yard target. They not only landed very close to point of aim but grouped into .38 inch, which extrapolates to 1.52 inch at 100 yards.

After letting the barrel cool, I fired three rounds at 100 yards, forming a 1.38-inch triangle. Not bad for a century-old rifle and a “mature” shooter with open sights! I then placed the rifle firmly on the bags with the front sight at the 100-yard target, then gently adjusted the flip-up “ladder” aperture sight to approximately the same place.

After the initial experiments I slugged the four-groove bore, measuring the slug with a Starrett digital micrometer. The average diameter across the lands was .3036 inch, but the average diameter across the grooves was .3103, a little smaller than the .311 inch of .303 British bullets. This made me suspect the rifle might also shoot standard .308-inch .30-caliber bullets. Some .303s do, occasionally very well.

I tried 40 grains of Hodgdon Varget with the Nosler 220-grain Partition that grouped under 2 inches in the Ruger No. 1. Even though the Ruger had been scoped, the load shot considerably better in the iron-sighted Ross, in fact slightly under an inch.

During previous .303 experiments I had also found .30-caliber Partitions often shoot better than other .30-caliber bullets, probably because the exposed rear core “bumps up” the back of the bullet to fit slightly loose bores. The front core of Partitions is also a relatively soft lead alloy so expands well at modest impact velocities, as my friend Tom Brownlee demonstrated during a 1999 safari in Namibia. Tom took two rifles, one a Lee-Enfield he restocked himself, using 180-grain Partitions.

In the Ross, the two roundnose bullets grouped slightly tighter than the two Sierra spitzers, which had to be seated deeper to fit in the Ross magazine. This might be due to the roundnose ogives being closer to the lands.

The cases were new Winchesters originally purchased for the 2011 article, and they came out of the Ross chamber only slightly expanded over their unfired dimensions. Many Ross rifles used in World War I had their chambers reamed larger in an attempt to aid extraction, both due to dirt and British war-production ammunition often being somewhat variable in dimension. My rifle has Canadian and British proof-marks on both the barrel and receiver ring, indicating it went overseas, but evidently still has a normal chamber.

Another possible cause for battle jams might be the bolt itself. Obviously, the body does not rotate, and in the 1910 action the bottom of the bolt has longitudinal slots milled on each side, matching a pair of steel rails in the bottom of the action. The bolt runs very slickly and precisely when clean and oiled, but the system probably did not help in mud and snow.

Ross rifles always enjoyed an excellent reputation for accuracy, probably due to fine tolerances and such features as the bolt-alignment slots. They were very popular with target shooters, and even after they failed on the front lines many snipers used Rosses. A First Nations Canadian soldier named Francis Pegahmagabow was credited with 378 confirmed kills in World War I (more than any other sniper) using a Ross.

My rifle is obviously accurate, but like some sporterized military rifles is also something of a mystery. Was it originally a standard Mk. III with a 30.5-inch barrel or one of the few “home guard” models with shorter barrels used in both Canada and England? One Internet forum contained a post from an older Canadian who said that “a couple of gunsmiths” in Quebec specialized in turning former military Rosses into hunting rifles.

Unfortunately, many Ross rifles were not given serial numbers, and when they did it was often stamped on the stock. The stock on my M-10 has been sanded smooth, and a no-name ventilated, white-line recoil pad added. (Contrary to what some hunters believe, Roy Weatherby did not invent white-line spacers. Instead they were developed by custom gunsmith Frank Pachmayr before World War II.) Some Rosses had a serial number stamped on the barrel, common before many countries made serial numbers on the action mandatory, but mine does not. Two letters and one numeral are haphazardly stamped on the underside of the action just behind the recoil lug, but are they a serial number?

Ross rifles are also something of a mystery, so mine definitely fits right in. But it shoots!