.28 Nosler Mountain Carbon Rifle

Shooting a Big 7mm

feature By: John Haviland | January, 20

The Mountain Carbon was the brainchild of Jeff Sipe, Nosler’s rifle division manager. Sipe said four essentials contribute to an accurate rifle and enable shooters to take advantage of that accuracy.

One is a good barrel. Sipe knew a carbon fiber-wrapped barrel was needed in order for the rifle to weigh 6 pounds, though he was hesitant. He previously headed up operations at Montana Rifle Company before going to work for Nosler a couple years ago.

“I bucked the trend in carbon- wrapped barrels for years because of technical issues and because the barrels just had not been tested enough,” he said. “Plus, we could make steel barrels just as lightweight.”

PROOF starts the manufacturing process with a 416R stainless steel barrel made by its firearms division. Barrel blanks for the Mountain Carbon are machined down to reduce the profile and weight, leaving a full-diameter section at the rear for a threaded barrel shank and at the muzzle with 5⁄8x34 threads to screw on a muzzle brake or suppressor. The barrel is wrapped with carbon fiber saturated with PROOF’s proprietary matrix resin. The Mountain Carbon’s 24-inch barrel has a “Sendero Light” contour that measures 1.113 inches in diameter ahead of the barrel shank and tapers to .80 inch at the threaded front.

PROOF’s carbon-fiber barrels feature a couple of benefits. For one, the barrels are stronger and up to 64 percent lighter than an all-steel barrel of the same contour and length. Carbon fibers are also said to rapidly dissipate heat along the length and through the walls of the barrel, so a barrel cools rapidly to maintain accuracy when firing a long string of shots. The rapid cooling also prolongs bore life.

After firing 50 .28 Nosler cartridges over several shooting sessions, a peek into the Mountain Carbon’s bore with a Lyman Borecam showed a few streaks of copper-fouling here and there on the top of the rifling lands. Smears of powder fouling coated the bore, which is expected when burning about 80-some grains of powder with each pull of the trigger. After cleaning the bore, the Borecam revealed only a couple of slight rough spots below the surface at the junction of the lands and grooves. The remainder of the bore was smooth as glass.

Sipe said mating that good barrel to a properly-prepared receiver is the second step in building an accurate rifle. The Mountain Carbon is based on Nosler’s Model 48 receiver. “The action has tight tolerances and the bolt is hand-fitted to the receiver,” Sipe said.

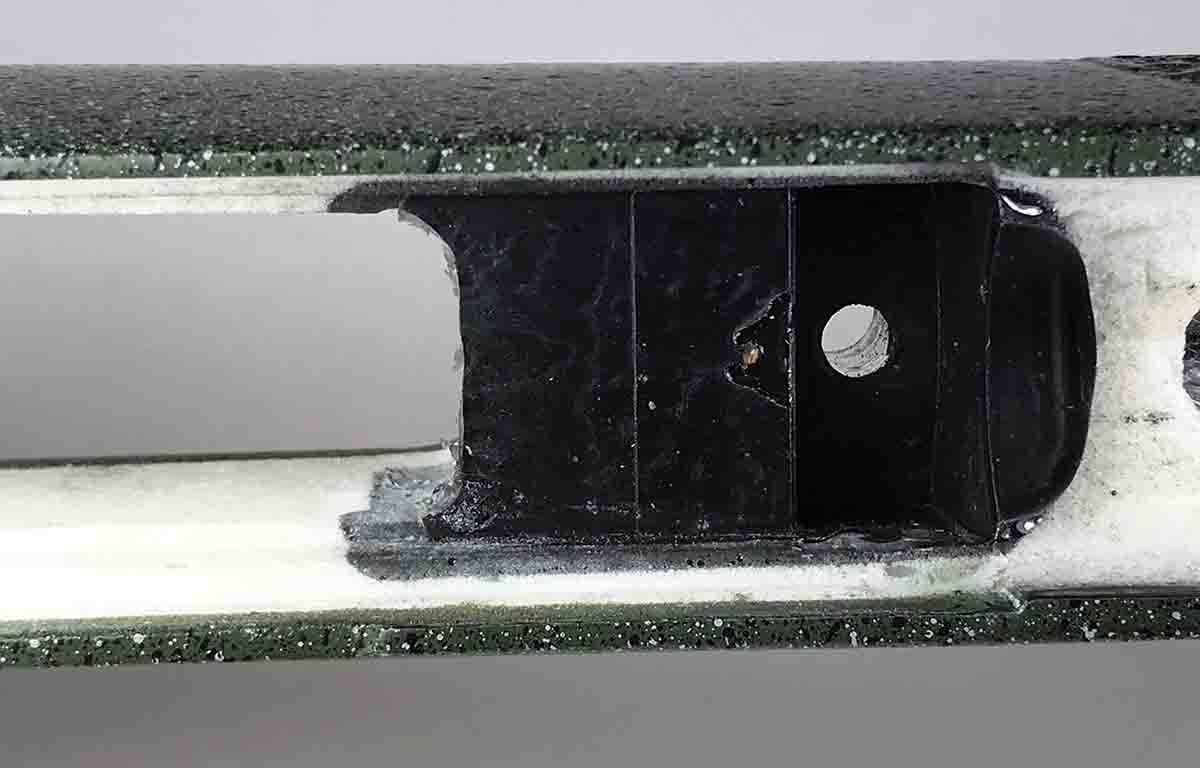

The stock is the third part of the accuracy equation. The barreled receiver is joined to a Manners Elite Hunter 6 stock that Nosler had slightly altered for the Carbon Hunter. It weighs 22 ounces. The stock has a foam-filled core with harder material between the recoil lug mortise and magazine opening and the cross brace in front of the hollow for the trigger assembly. The recoil lug and the tang area are glass bedded. The rear and front action screws pass through aluminum pillars cemented into the stock. The carbon fiber shell is painted green.

Stock fit is the final piece that links an accurate rifle to the shooter. A stock with as much surface area as possible distributes kick widely over the body to lessen felt recoil. The forearm looks slim compared to the large-diameter barrel. However, it fills the hand, and textured panels on both sides of the forearm and grip provide a sure grasp. The stock’s full comb cushions the cheek and a slight forward slant pulls it away from the face during recoil. The wide butt with a .75-inch thick Decelerator recoil pad shields the shoulder. A swell on the grip fills the palm and a hollow behind the grip supports the base of the thumb.

The Mountain Carbon is chambered in a short-action Model 48 in the 6mm and 6.5 Creedmoor. A standard-length action is used for the .26, .28, .30, .33 Nosler and .300 Winchester Magnum. Sipe said the .28 Nosler is by far the most popular. The 6.5 Creedmoor is a close second, followed by the .26 Nosler.

Over the last few months I’ve been shooting a Mountain Carbon .28 Nosler to see if the rifle lived up to its sub-minute of angle accuracy guarantee and how well it shot from field positions. The rifle weighed 6 pounds, 2 ounces. The addition of a Leupold VX-3i 4.5-14x 50mm scope clamped in Talley Lightweight alloy scope mounts brought the weight up to 7 pounds, 6 ounces.

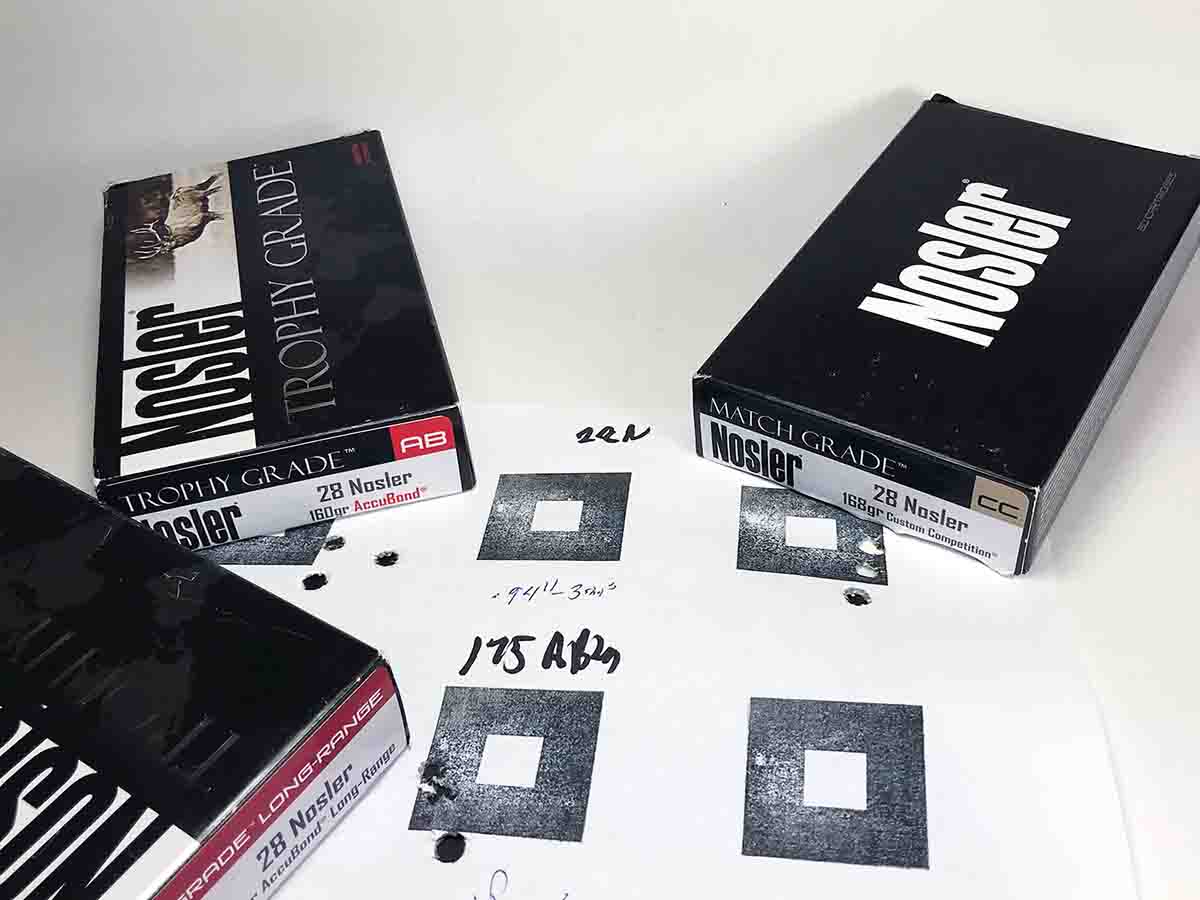

Nosler does not stipulate what ammunition or how many shots are required to meet that accuracy promise. Shooting factory loads with the rifle supported on a bench, the rifle provided three-shot groups as tight as .63 inch with Nosler Match Grade 168-grain Custom Competition loads, .86 inch with Nosler Trophy Grade 175-grain AccuBond Long Range cartridges and .72 inch with Nosler Trophy Grade 160-grain AccuBond loads. An inch was about the average size of three, three-shot groups with the three factory loads.

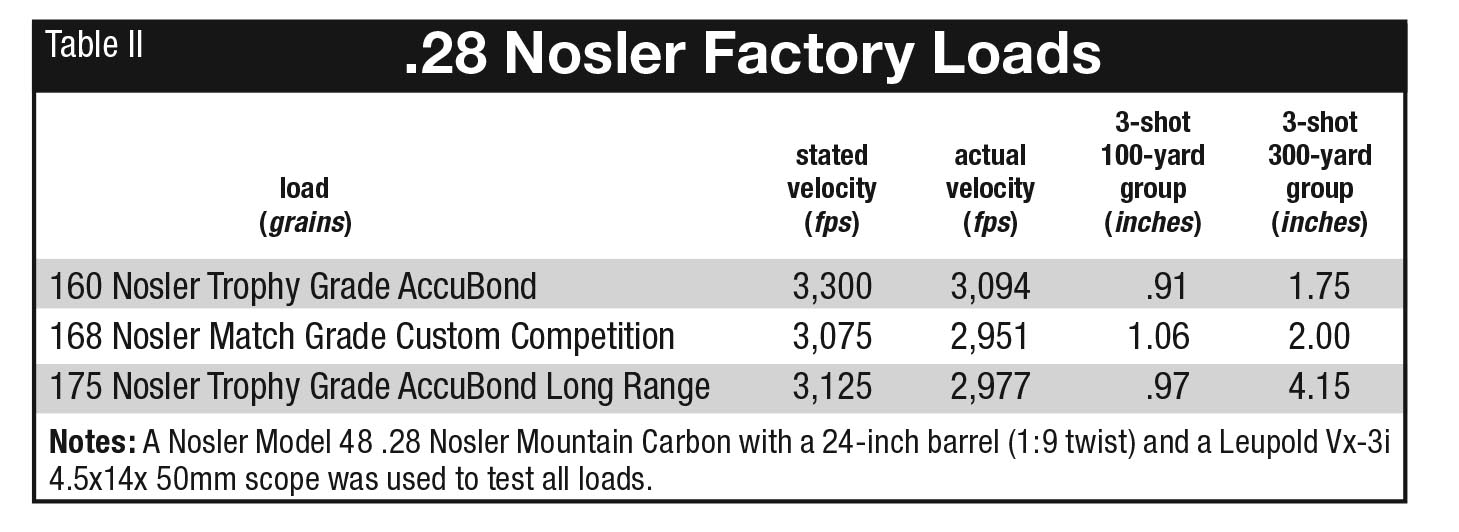

Nosler lists impressive velocities for its .28 Nosler ammunition from a 26-inch barrel. Velocity of the Nosler loads chronographed 10 feet in front of the Mountain Carbon’s 24-inch barrel came up about 100 to 200 fps short of those stated velocities.

Several handloads produced fairly high velocities. IMR-7977 and Reloder 33 pushed 160-grain AccuBonds at 3,200 fps. Reloder 33 also fired 168-grain AccuBond Long Range bullets at nearly 3,100 fps. Extreme spread of velocity was also low with several hand-loads. Nosler 160-grain Accu-Bonds had a 25-fps extreme spread with Magnum and 30 fps with IMR-7977. Nosler 168-grain AccuBond Long Range bullets recorded a 15-fps extreme spread with Retumbo and IMR-7977, and Hornady 162-grain Spire Point bullets had an extreme spread of 12 fps with IMR-7977.

The .28 Nosler’s maximum cartridge length is 3.340 inches. I seated Berger 168-grain VLD Hunting bullets for that cartridge length, which resulted in the start of the ogive of the bullet set well inside the case neck. The rifle’s magazine accepts cartridges no longer than that, so the bullets could not be seated out any farther. I went ahead and shot the three cartridges, and the Bergers formed a tight .60-inch group.

I shot the three Nosler factory loads at 100-yard targets with the rifle supported on a bench then checked to see if that level of precision transferred to the prone hunting position when shooting at targets at 300 yards. The Mountain Carbon put three 160-grain AccuBond bullets in .72 inch at 100 yards. The rifle was nearly as steady shooting prone with it braced on a Harris bipod clamped on its front sling stud and a daypack under the toe of the stock. A somewhat higher comb would have helped provide more of an anchor for my head. Still, three AccuBonds grouped in 1.75 inches at 300 yards.

Next were 168-grain Custom Competition loads that printed a .91-inch group at 100 yards. Three of the bullets formed a 2-inch group at 300 yards. Three 175-grain AccuBond Long Range bullets landed in .94 inch at 100 yards. Recoil was starting to add up, though, with a noticeable rearward jolt and the rifle twisting to the right. Shooting prone, there was some shake to my trigger finger in anticipation of recoil. Three bullets landed in 4.15 inches at 300 yards.

Nosler’s Mountain Carbon was worth the wait. I was more than happy with all the shooting that showed the lightweight rifle had lived up to its sub-MOA accuracy guarantee and enabled me to take advantage of it.