Rife Accuracy

The Key is Better Ammunition

feature By: Brian Pearce | July, 20

Beginning in 1977, Federal Cartridge introduced its Premium line of factory ammunition that included both big-game hunting bullets and match loads, which raised the ante for competing companies. The popularity of this product line soared and has been expanded over the years, as shooters and hunters endorsed the concept of improving terminal performance and accuracy when compared to conventional loads. It was only a matter of time until all other major ammunition companies began offering their own top drawer loads to compete. A few of today’s examples include Hornady Custom and Superformance, Nosler Custom Trophy Grade and Handloaded, Black Hills Ammunition, Winchester Ballistic Silvertip and Remington Premier. Generally speaking, these loads contain custom bullets, carefully selected powders, and in some instances, weight sorted cases with primer pockets uniformed, etc., along with match primers. Special tooling and loading procedures are often used to assure bullets are seated without runout, all of which explains and justifies their greater cost.

Back in the late 1970s I obtained a Browning FN High Power Safari Grade rifle chambered in .300 Winchester Magnum. I was already a regular at the gun shop and friends with the owner, so he threw in one box of Winchester 180-grain Power-Point ammunition, a box of Remington 180-grain Core-Lokt and a box of the relatively new Federal Premium load containing 200-grain Sierra BTSP bullets. I hurried home and mounted a new Leupold Vari-X III scope and retired to my shooting bench. I started with handloads that had been assembled specifically for a Winchester pre-’64 Model 70 of the same caliber, which grouped around one inch using 180-grain and 200-grain Nosler Partition bullets. Next, the Winchester factory loads were tried, but groups opened up to around 2 to 2.5 inches, and the Remington load more or less duplicated those group sizes.

This story is related for a couple of reasons. First, it confirmed that Federal Premium ammunition was indeed more accurate and justified its higher cost – at least in my mind. Second, through careful handload development, the accuracy of this great rifle was further improved.

I frequently have the opportunity to test factory loads, and the difference between entry level and top-notch loads from the same company can be significant. One recent example comes to mind wherein entry level .223 Remington loads would only produce 3- to 5-inch groups, while top-notch loads from the same company consistently yielded groups that hovered between .75 and 1.25 inches from the same rifle. In dismantling sample cartridges for evaluation, there were no perceptible differences in the case. However, the powder type, charge weight and bulk density were significantly different, as were the primers. Furthermore, the top loads featured notably higher quality bullets and showed very little runout in loaded cartridges, while the entry level loads showed notable runout variances. Many top factory loads are engineered for accuracy, which explains why rifle manufacturers that offer an accuracy guarantee always require the use of high quality ammunition. In thumbing through my notes compiled over the past couple of years, wherein I have tested a variety of rifles in many different calibers, top-notch factory loads are often capable of MOA accuracy while, occasionally, some rifle and load combinations have cut that figure in half.

SAAMI regulates pressures for almost all common rifle cartridges; however, factories usually keep pressures at least six to 10 percent below industry maximum average pressures. There are several reasons for this, but it’s primarily due to variances in rifles and the changes in actual pressure from one gun to the next and environmental changes that can raise pressure.

Before settling on a particular factory load, it is noteworthy that factories often change powder charge and type, which can potentially impact accuracy. With every lot number change, even if velocities do not change, accuracy, point of impact, barrel harmonics and other variables can change performance.

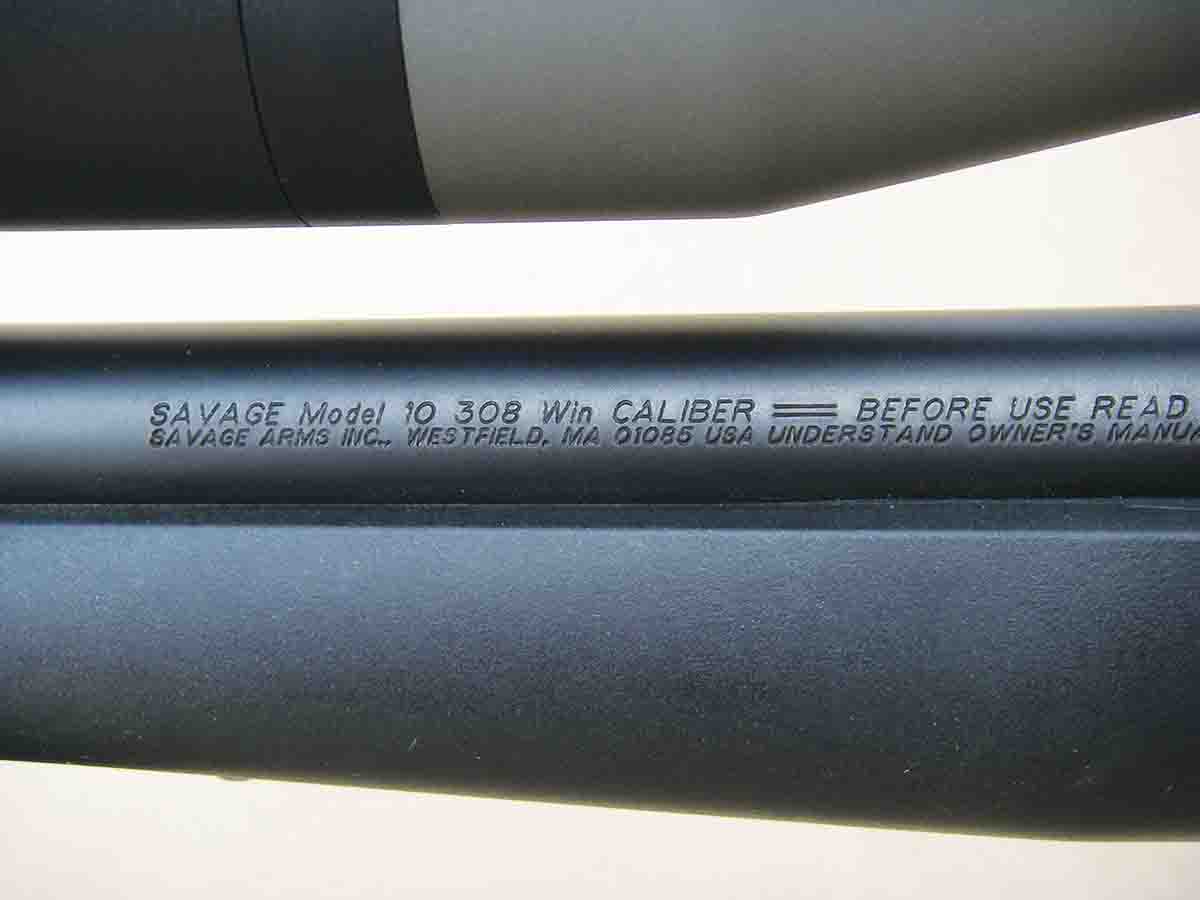

First up was a Savage Model 10T Tactical chambered in .308 Winchester with a 24-inch heavy barrel featuring 5R rifling, one of the more accurate production rifles I have worked with. A variety of factory loads were tried, but four top-notch factory loads from Black Hills Ammunition, Nosler, Federal Premium and Hornady displayed accuracy advantages. Each load was tested with a fouled barrel from that particular load. And three groups were fired with each load (four shots per group), with the averages presented in Table I.

As indicated, the most accurate factory load was Nosler Trophy Grade featuring the 165-grain Ballistic Tip, which produced an average group size of .65 inch, while the combined average for all three factory loads from Black Hills, Nosler, Federal and Hornady was still an impressive .8125 inch.

Handloads for the .308 were developed using multiple powders; however, the primary focus was on Hodgdon Varget combined with the proven Nosler 165-grain Ballistic Tip bullet and CCI BR-2 primers. Bullets were seated to the same maximum overall length as listed by SAAMI (2.810 inches). NoslerCustom cases were full-length sized to the same specifications as factory loads.

The accuracy sweet spot was found with 44.3 grains, which yielded 2,744 fps and had a three-shot group average of .447 inch (rounded to .45 inch). It should be pointed out that this particular load was not simply thrown together. Rather, components were carefully selected and great attention was taken to assure bullets were seated without runout. Furthermore, loads were assembled using lighter and heavier powder charges in an effort to find the accuracy sweet spot for this rifle. The best accuracy was between 2,725 and 2,750 fps. It just doesn’t get any better than Varget powder for accuracy in the .308.

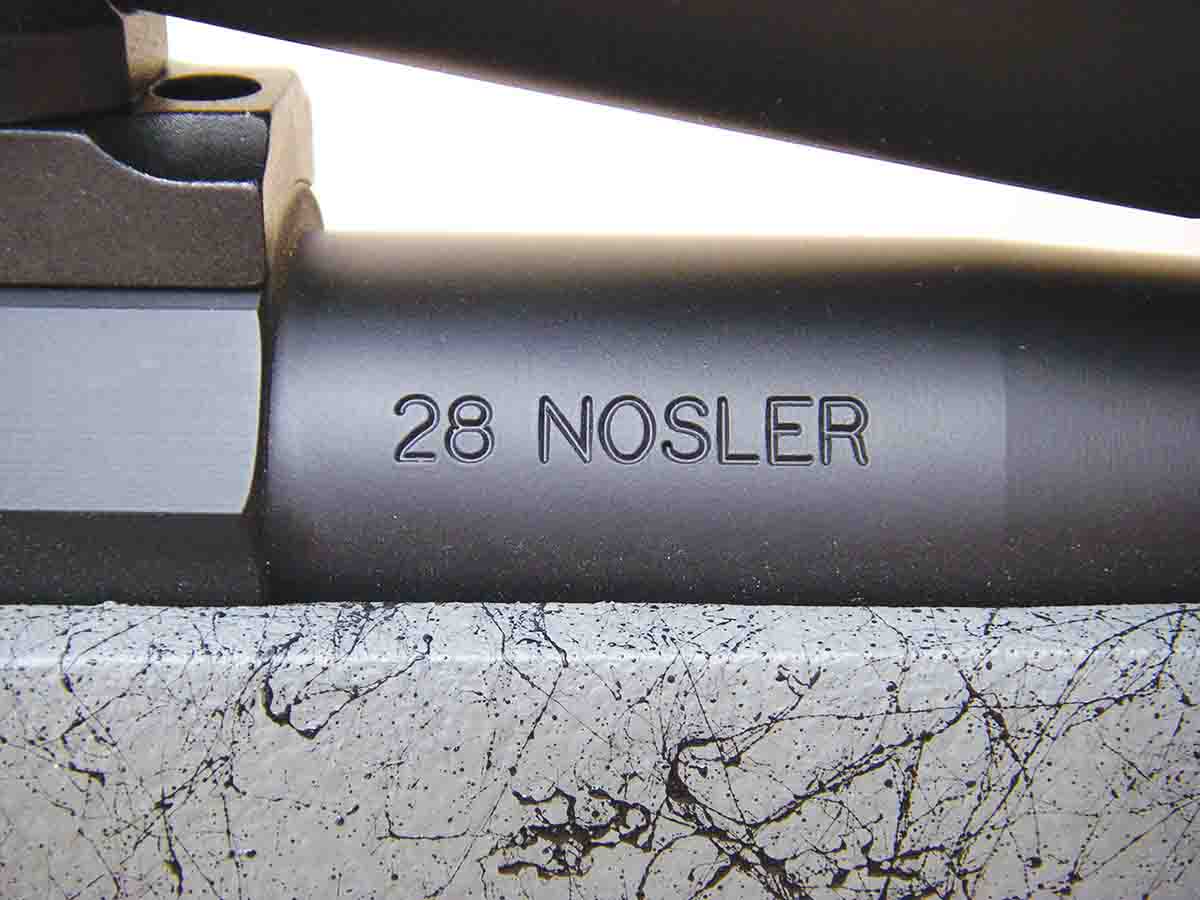

Next was a Nosler Model 48 Patriot rifle chambered for the excellent .28 Nosler cartridge (Table II). This was a much simpler comparison, as only two factory loads were tested that included the 160-grain AccuBond bullet advertised at 3,300 fps and a 175-grain bullet listed at 3,125 fps. The rifle displayed an accuracy preference for the 160-grain load that has an actual velocity of 3,322 fps. The three-group average was .743 inch (rounded to .75 inch), which might be tough to improve upon, particularly with Nosler’s high standards for case preparation, high-quality components and precision loading methods.

In developing handloads with the 160-grain Nosler AccuBond bullet, Hodgdon Retumbo and Alliant Reloder 25 powders were tried. Both proved capable of reaching velocities up to 3,375 fps, but again, I was trying to find the accuracy sweet spot rather than “outrun” factory load performance. All powder charges were weighed and cases primed with Federal 215GM primers.

After a series of testing with load velocities ranging from 3,175 to 3,375 fps, the best accuracy was observed between 3,275 and 3,325 fps. I could only detect a small difference in accuracy between Reloder 25 and Retumbo, at least when velocities were within that scope. Bullets were seated to an overall cartridge length of 3.344 inches, all powder charges were weighed and special care was taken to assure bullets were seated with minimal runout using Redding dies. The best groups using Retumbo averaged .55 inch, while groups with Reloder 25 averaged .65 inch. This was not a huge accuracy advantage over high quality Nosler factory loads. However, it was still an improvement, and there is always a certain satisfaction in using your own handloads.

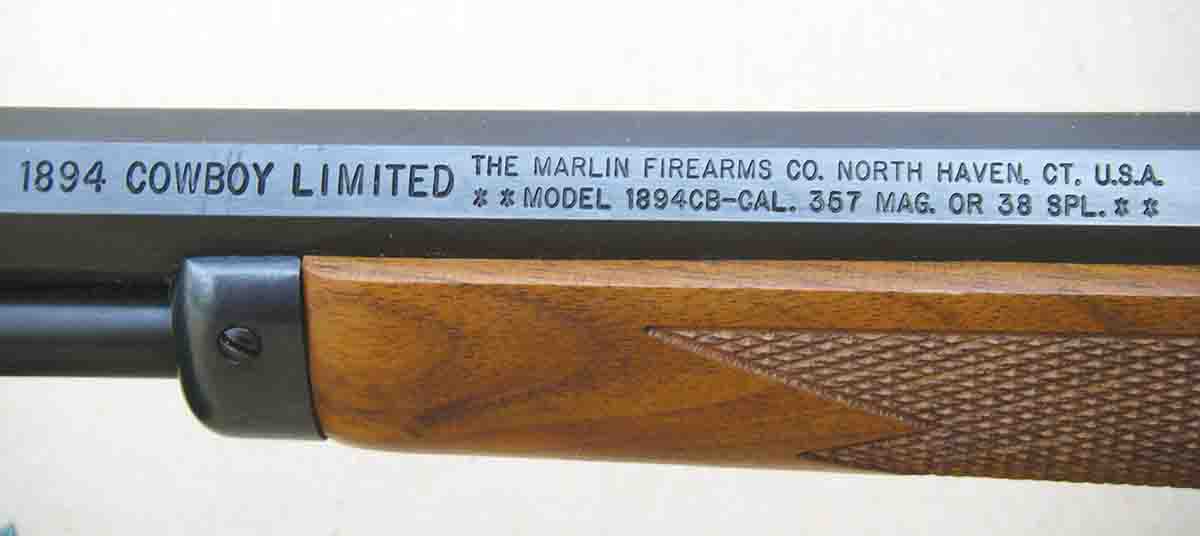

I wanted to include a straight wall cartridge in this discussion, as they are notably different than a bottleneck cartridge. For this purpose, a Marlin Model 1894CB Cowboy .357 Magnum was selected for several reasons. First, it is one of the most useful and practical small-frame lever-action calibers offered and its popularity has been growing for decades. It can serve admirably for home or property protection, cleanly take a variety of game up to deer-sized animals, produces modest recoil, offers high efficiency and in a good rifle is accurate. While it is often touted as a good choice as a “companion rifle” to a sixgun of the same caliber, I must emphasize that it is good enough as a rifle (or carbine) cartridge to stand on its own merits.

The rifle features a 24-inch barrel with Ballard style rifling and has served me in several roles since the 1990s. It is equipped with an XS aperture rear sight and white stripe post front. It has proven accurate with both cast and jacketed bullets and has been used in the field for ground squirrels and to hunt black bear. I have used it to evaluate a variety of factory loads and handloads, and even pre-production loads from two ammunition factories.

Most .357 Magnum factory loads usually push 158-grain jacketed softpoint or hollowpoint bullets to around 1,600 to 1,800 fps from the 24-inch barrel. Four-shot groups fired at 75 yards typically range from 1.5 to 4 inches. Two factory loads that have consistently given top accuracy include Hornady’s Custom 158-grain XTP-HP and Black Hills Ammunition’s 158-grain JHP. Velocities are 1,804 fps and 1,721 fps, respectively. While 75-yard groups for each load can occasionally drop just below 1.5 inches, they both typically group into 1.5 to 1.75 inches, respectively.

I have been able to duplicate the above velocities and accuracy by using Hornady 158-grain XTP-HP bullets loaded with either 14.5 to 15.0 grains of Alliant 2400 or Accurate No. 9 powders capped with a CCI 500 primer. However, tests indicated groups tended to improve as velocity was increased. The problem is that both of these powders reach maximum average pressure (35,000 psi) when velocity hits around 1,800 fps. I was curious if accuracy could be further improved if velocity was increased to 2,000 fps or more with the same Hornady XTP bullet used in the above factory loads and my handloads. While there are some relatively new powders available to handloaders that may reach this velocity, including Accurate No. 11FS, Alliant Power Pro 300MP and others, I settled on Hodgdon Lil’Gun for this application.

While Lil’Gun powder can produce significant muzzle and barrel/cylinder gap flash in sixguns, it performs marvelously in .357 Magnum rifles. For example, handloads were assembled in Starline cases, with 19.0 grains reaching 2,066 fps while 20.0 grains reached 2,117 fps, both of which were ignited with a CCI 550 primer to assure proper powder combustion. In spite of their impressive velocities, both loads are within industry maximum pressure guidelines.

From a sandbag with my left hand preventing the forearm from touching the sandbags, both loads were checked for accuracy. The 19.0-grain load produced three groups that averaged just over 1.75 inches. The 20.0-grain load yielded one group that was under .75 inch, but the three group average was still under one-inch! Again, the goal was not to reach the highest velocity possible, but to increase accuracy. The notably higher velocity of my handloads when compared to factory loads was just an added bonus. As these words are written, Idaho ground squirrels are thick, and this load and cartridge combination offer amazing terminal performance with superior accuracy.

In spite of today’s top-notch factory loads featuring highly precision components and utilizing powders that offer amazing shot-to-shot consistency, excellent accuracy and other benefits, knowledgeable handloaders can still improve accuracy and often performance.

.jpg)