Light Gunsmithing

For Want of One More Round

column By: Gil Sengel | July, 20

Despite this knowledge, some hunters use spandex gadgets stretched over the buttstock that hold an extra couple of rounds. Others have been known to carry spare cartridges between the fingers of their forward hand, or clinched in their teeth just in case. This seems a bit silly when in 99 percent of hunting situations involving non-dangerous game, there is only time to fire one or maybe two rounds.

Surprisingly, some people who hunt with bolt guns also feel the need for more ammunition readily at hand. This should be easy. Just buy a new rifle with detachable tin or plastic magazines. While these are available holding all the rounds we will likely fire in a lifetime of big-game hunting, they are not the solution. What is really wanted is just “one more round.”

This desire to add an extra round to the magazine capacity of common bolt guns seems to be caused by the last 50 years or so of cartridge development. Newer cartridges often use larger diameter bases (heads) than the common .30-06. However, most all bolt-action military and sporting receivers for the last 120 years have been proportioned for the old ’06 or 7.9x57mm. If these are then rebarreled to a Remington Short Action Ultra Magnum, Winchester Short Magnum, etc., the larger diameter case means one less cartridge will fit in the magazine. Custom riflesmiths, being a very astute bunch, picked up on this and had the problem solved even before rifle owners knew it was something that might need fixing. The solution was making a new, deeper magazine box which, when requiring a one-

Another solution seems to have been devised in either Germany or England prior to World War I. It consisted of a one-inch or so extension to the existing magazine box but made as a separate piece that was entirely exposed. Attachment to the bottom of the magazine was exactly like a military floorplate. Some were hinged at the front like modern floorplates and secured at the rear by the little lever so dear to the hearts of German riflemen. Unfortunately, when hanging down this far, totally exposed, there was a tendency toward damage and looseness if handled roughly.

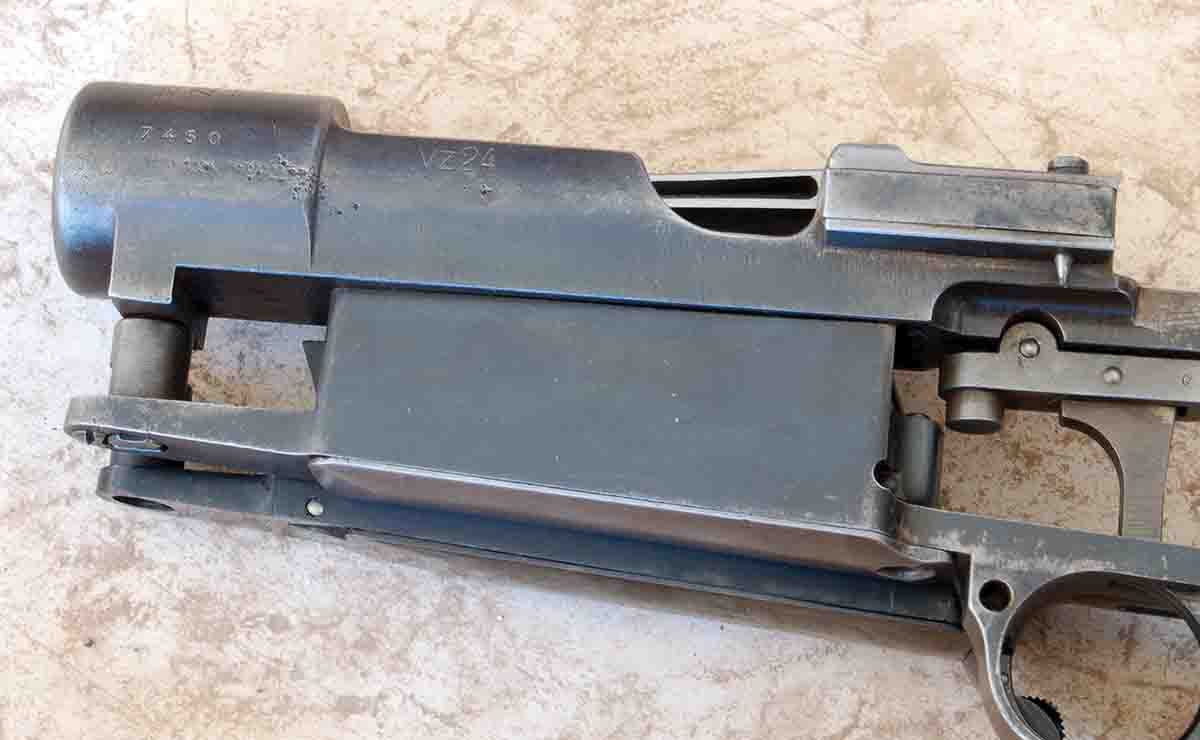

There is, however, an inexpensive way for riflefolk who do some of their own gun work to obtain this custom look – and one more round in the magazine. The basis can be any Mauser action with a military box magazine or 1903 Springfield. The thick floorplate is held to the bottom metal by two machine screws threading into blind holes, leaving a clean outer surface. Though not detachable, this is a small price to pay for deleting a complex latch mechanism. Material for the new floorplate is ½x1½ inch cold-rolled mild steel. Aluminum can also be used to reduce weight. Length depends upon action length. Cold-rolled steel is preferred because the wide dimension surface is flat and smooth. New metal comes in 20-foot lengths, which is a bit much. Scrap dealers have short lengths available for a few dollars.

For the ’03 Springfield shown in the photos, the huge hole of its ridiculous latch must be covered by a piece of steel slid into the rear floorplate notch. A drop of solder at the rear holds it in place. An 8x32-tpi clearance drill hole is then drilled down to the new floorplate, followed by a tap drill hole in the new metal. After tapping the hole in the floorplate a machine screw is fit, pulled tight and the hole for the front attaching screw drilled. It should be noted that the front tang generally has some metal milled away to reduce weight. A steel filler can be made and soldered in, but the tang is usually thick enough without doing this.

With front and back screws in place, the inside of the magazine box is deeply scribed into the floorplate. Now some milling is unavoidable but is very simply done on one of the import bench-top drill/mills so popular with hobbyists in the last 30 years. Any serious gunsmith will have one of these, or a milling attachment for his metal lathe.

It is now necessary to profile the 1½-inch wide floorplate. Put it back on the bottom metal and trace around the outside of the magazine box with a silver felt tip pen. Note the uniform mark in the photo. Hacksaw and file down to the outside edge of this line, which will leave a small overlap of the magazine box. If there are gaps in the inletting between box and stock wood, they will be covered by the new floorplate.

All that remains is to break the sharp edges along the bottom of the floorplate. Shown in a junk stock, the new metal still requires some of this file work, but the heavy lines are striking. Its new home, a .358 Norma Magnum on a Springfield 03-A3 action, promises to be a real eye-catcher with its thick floorplate – and it will hold one more round!