Remington Model 30 Express

A Classic Rifle Bar None

feature By: Layne Simpson | July, 21

Meanwhile, the Lee-Enfield remained in production and because manufacturing capabilities could not handle the addition of the P14 rifle, huge contracts were awarded to Remington and Winchester. In addition to producing rifles at its Ilion, New York, plant, Remington leased more than 30 acres of factory floor space from Baldwin Locomotive Works in Eddystone, Pennsylvania, where as many as 6,000 P14 rifles were produced each day.

Due to sufficient inventory of Lee-Enfield and P14 rifles on hand, the British canceled the Remington and Winchester contracts in 1916. When American doughboys headed “over there” in 1917, there was no way production of the 1903 Springfield at Rock Island Arsenal and Springfield Armory could keep up with the projected demand. With three huge plants already geared up to produce the P14 Enfield, some bright soul (rumored to be a Remington official) convinced U.S. Army brass that the rifle could easily be modified to handle the .30-06 Springfield cartridge. Contracts were awarded in 1917 and a British-designed rifle became known as U.S. Rifle, Caliber .30, Model of 1917. The war officially ended in November 1918, and while some sources disagree on how many rifles were actually produced, in Bolt Action Rifles (1984) author Frank de Hass indicated approximately 545,511 at Winchester, 545,541 at Remington-Ilion and 1,181,908 at the Eddystone plant.

When transforming the P17 receiver into one more suitable for sporting use, huge steel wings protecting the rear aperture sight were machined away and a weight-reduction cavity in the bridge of some receivers was filled in. Those modifications resulted in an attractive contour of the same height as the receiver ring. Adding a serrated strip along the top of the receiver was a nice touch.

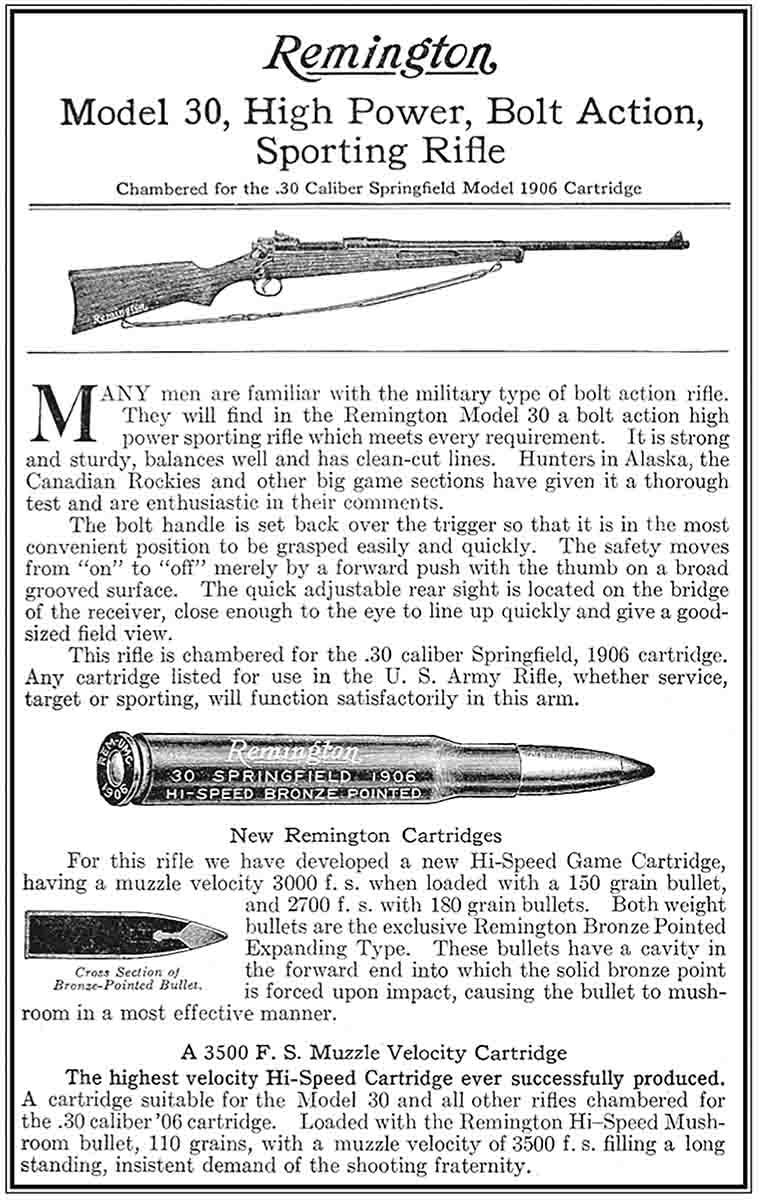

The Model 30 was introduced with a smaller version of the P17 aperture sight. Depressing a spring-loaded plunger allowed the aperture to be moved up a ramp graduated for distances out to 500 yards. The sight lacked windage adjustment, but it could be drifted laterally in its dovetail. Within a few years, it was replaced by an elevator-adjustable, open sight attached to the barrel with a steel band.

The original safety was retained, and that was a very good thing. Thumbing it to the rear deactivates the firing pin by camming the cocking piece rearward, and away from resting against the sear. Bolt rotation is also blocked. A huge, serrated lever makes the safety easy to operate when wearing gloves, and as should be on a big-game rifle, it can be operated quietly.

The P17 bolt was only slightly modified for the Model 30. Adding a third gas escape port allowed sufficient access for riveting a guide rib to the outside of the bolt body. In its original battle rifle form, the bolt cycled fairly smoothly and the guide made it even more so by reducing binding. The dogleg bolt handle also remained. While it never won a single beauty contest, it speeds up bolt cycling, and during wintertime hunts, it is easy to grasp with a cold, wet and possibly muddy hand. Hugging close to the stock makes it good for carrying in a leather scabbard when hunting from horseback. The bolt is removed from the receiver by using the rim of a cartridge to engage a V-notch at the front of the release and pulling outward.

Disassembly is easy. With the bolt retracted, pull the safety to its rearward position and then push the bolt all the way forward and rotate to its locked position. While holding the edge of a twenty-five-cent piece between the front of the cocking piece and the rear of the bolt shroud, lift the bolt handle and the coin will be trapped in place. Remove the bolt from the receiver and rotate the firing pin assembly counterclockwise for removal.

The original two-stage trigger of the P17 was converted to single- stage with a bit of creep followed by a fairly consistent, 5-pound break. Bolt lift during firing pin compression measures close to 7 pounds compared to less than 5 pounds for the Remington 700. Keeping the cocking cam surface of the bolt greased helps. The firing pin strike energy is about 20 percent greater than in the Model 700, so no worries about igniting primers with hard cups. Locktime is 5.2 milliseconds compared to 3.0 for the Model 700 long action, a difference my brain is not quick enough to detect.

Barrel length of the original Model 30 was 24 inches and advertised weight was 8 pounds. There was no checkering on the American black walnut stock, but the trim forearm had a finger groove on each side and a Schnabel-style tip. A canvas carrying strap had hook-style swivels shaped to engage steel eyes in the stock. Some of the early Model 30s are rather crude in appearance, but improvements were eventually made. In 1926, the action was converted to cock-on opening, the trigger was improved and the barrel was shortened to 22 inches. The stock was checkered and reinforced by a steel cross bolt between the recoil lug mortice and the cutout for the magazine. The name was changed to Model 30 Express.

My Model 30 Express in .30-06 was built in 1930. It weighs 7 pounds, 6 ounces and its bolt glides to and fro quite smoothly. Cartridge feeding with spitzer and roundnose bullets is totally reliable. The barrel measures 1.250 inches at the receiver, and from there it tapers to a muzzle diameter of .600 inch. Its serial number was roll-marked on the receiver ring, engraved on the bolt and stamped into the bottom of the barrel channel of the stock.

Telescopic sights were years away from really catching on among hunters, but holes drilled and tapped in the tops of the receiver bridge and ring indicate Remington’s crystal ball was working. Headless filler screws in the holes of my rifle appear to have never been removed. A Lyman 48R or Redfield 102R aperture sight attached to the receiver was an extra-cost option from the factory, and my rifle has the latter. I wanted to hunt with it, but with the rear sight adjusted as low it would go, shots on paper were too high. The front sight is dovetailed to an integral ramp on the barrel. Its bead was so small I could hardly see it in good light, and it vanished by the time deer started moving late in the day. A taller sight with a larger bead fixed both issues.

In those days, the factories had employees who checkered stocks by hand and many were women. A magnification glass reveals 20 lines-per-inch on my stock, with only the occasional minor border runover. Diamonds still sharply pointed indicate the rifle might have been carried only occasionally through the decades, but it was obviously shot. Somewhere along the way, a previous owner installed a recoil pad and in doing so, shortened the stock way too much for me. Attaching a lace-on leather pad increased length of pull to 13 inches, still a bit short but I can live with it when wearing heavy clothing.

Soon after buying the rifle, I slugged its bore and came up with a groove diameter of .3082 inch. More recently, I took a slow tour inside with a Lyman Borecam and while the lands are nice and sharp, there is light pitting. Chemist James E. Burns invented the first non-corrosive primer, and Remington introduced it in its Kleanbore ammunition in 1923. It probably took quite a few years before ammunition with corrosive primers was no longer lurking on the shelves of gun shops, hardware stores and other places that sold it. If my rifle could only talk, I might know if the pitting in its barrel was caused by that ammunition. Considering the condition of the rifle otherwise, I doubt if it was due to owner neglect.

I am not sure how long the Express name was used, but a rifle with the exact same stock styling as mine is identified in a 1932 A.F. Stoeger catalog as Model 30A. In addition to four Remington rimless chamberings, the catalog listed the .30-06 and 7x57mm Mauser. The rifle had an elevator-adjustable sight on its barrel and was priced at $52.75. The Model 30R carbine with a 20-inch barrel and no checkering on its stock and was $48.75. Priced at $66, the Model 30S Special Grade with a Lyman 48R sight had a stock styled more like we see on today’s rifles. Respective advertised weights were 7, 7.25 and 8 pounds.

Until the introduction of the Winchester Model 70 in 1937, the Remington Model 30 was the only sporting rifle of American make with an action long enough to handle the .300 H&H Magnum and .375 H&H magnum cartridges. Remington never offered them, but Griffin & Howe built custom rifles on the Model 30 action chambered for both. The Griffin & Howe rifle used by Ben Comfort to win the prestigious 1,000-yard Wimbledon Cup match at Camp Perry in 1935, was on a Model 30 action and it had a heavy Winchester barrel in .300 H&H Magnum. Why was the action so long? When designing the Pattern 13 Enfield, the British originally intended to replace the .303 with a cartridge similar to the .280 Ross. It was similar in length to the .300 H&H Magnum, so the length of the action was made accordingly.

While writing this, I spent a few minutes looking around to see if any famous people had used Model 30 rifles. According to early Remington literature, Norwegian explorer Roald Admundsen carried a Model 30 on expeditions, but which of his expeditions is unclear. He was first to reach the South Pole, but that was in 1912, eight years prior to Remington’s introduction of the rifle. Admundsen later led expeditions to the North Pole, where he and his crew partially depended on harvesting seal meat for survival. There was also the occasional hungry polar bear to deal with, so the North Pole is likely where he carried a Model 30.

The first big-game rifle Jack O’Connor gave to his wife, Eleanor, was a Model 30 in .25 Remington with a Lyman 48 sight. She used it to take her first mule deer in the Kaibab National Forest of Arizona. In 1935, Jack bought another Model 30 in .257 Roberts and had it restocked by Adolph Minar. It had a 2.5x scope built by Rudolph Noske of San Carlos, California, and Eleanor used it to take her first Arizona Coues’ deer.

With enough surplus parts remaining to make thousands more Model 30 rifles, Remington ceased production in 1940 while redirecting its manufacturing capability toward making weapons for World War II. During about 20 years of production, only 22,738 Model 30s were built, slightly less than the number of P14 rifles produced in four days at the Eddystone factory.