Light Gunsmithing

Set Trigger Basics Part II

column By: Gil Sengel | July, 21

Once popular on pre-1930 single-shot target rifles, all European cartridge rifles and most muzzleloaders, this trigger is rarely seen on new cartridge guns today. Why? Simply because today’s primers are more sensitive and uniform than ever. Extremely heavy mainsprings to guarantee ignition are no longer needed, so trigger pulls can be adjusted downward to the point where the added expense of a set trigger is no longer necessary.

Nevertheless, anyone who likes to shoot older guns, or their new reproductions, will eventually come across a rifle and pass it up because of fear of the set trigger. As noted in the previous column, there is nothing to go wrong except dirt or powder fouling buildup, which is easily remedied. If one is disassembled for entertainment, or someone starts filing on parts, then all bets are off!

The foregoing also applies to a slightly different set trigger. As one would expect, humans could not leave well enough alone. They also created two-, three-, four- and even five-piece triggers! Published drawings show these pieces to be tiny, oddly shaped things, no two of which are alike. Each pivots on a pin through the trigger box. This provides a simple way to determine the number of parts in any set trigger – just count the pins and subtract one for the setting trigger.

These set triggers do not have ground sear surfaces that slide apart in a normal sear/hammer relationship. Thus, there is nothing to wear, chip or break. When the setting trigger is pulled, tiny flat springs push each piece into proper alignment with the next to produce a state of equilibrium. A tiny movement of the firing trigger then disrupts this balance, causing the pieces to rotate out of the way, releasing an arm on the setting trigger to spring upward, firing the rifle. One early competitor remarked that his set trigger was so finely made that the rifle would fire if simply tipped up from horizontal to vertical!

Set triggers consisting of several parts are probably quite rare. I have seen very few. All worked perfectly except one that appeared to contain congealed oil. It took several weeks of soaking, but eventually all the little parts moved and the trigger functioned normally. Nevertheless, since one-piece set triggers can be set so light that most folks can’t feel contact with the trigger before it releases, what’s the point?

Another series of set triggers is that produced by Winchester. There were three in the group, with the Schüetzen Double-Set available on the Winchester single-shot rifle. It is the same as the one-piece triggers covered in the last issue. The two others in the series, the single set and close-coupled double set have small sear surfaces that slide apart, rather than being held in equilibrium. These wear and this is probably the reason many of them are found in non-working condition. If backing out the adjustment screw and cleaning doesn’t allow the trigger to set, it is worn, or worse, and will require parts to be made. This is far beyond the realm of the home gunsmith.

Now comes a modern set trigger. It was made by the M.H. Canjar Company in Denver, Colorado. This outfit produced many accessories for high-power and small-bore target shooters, but its main product was the Canjar Precision Trigger.

The Canjar trigger itself, however, was not a set trigger. It was a replacement for the military designs in the dozens of surplus bolt guns being imported in the 1960s through the 1980s. Canjar triggers were better than needed on sporting rifles, but at the time, many target guns were being built on surplus Mauser and Springfield actions. Virtually all custom varmint rifles were also built on these actions, and they needed triggers as well.

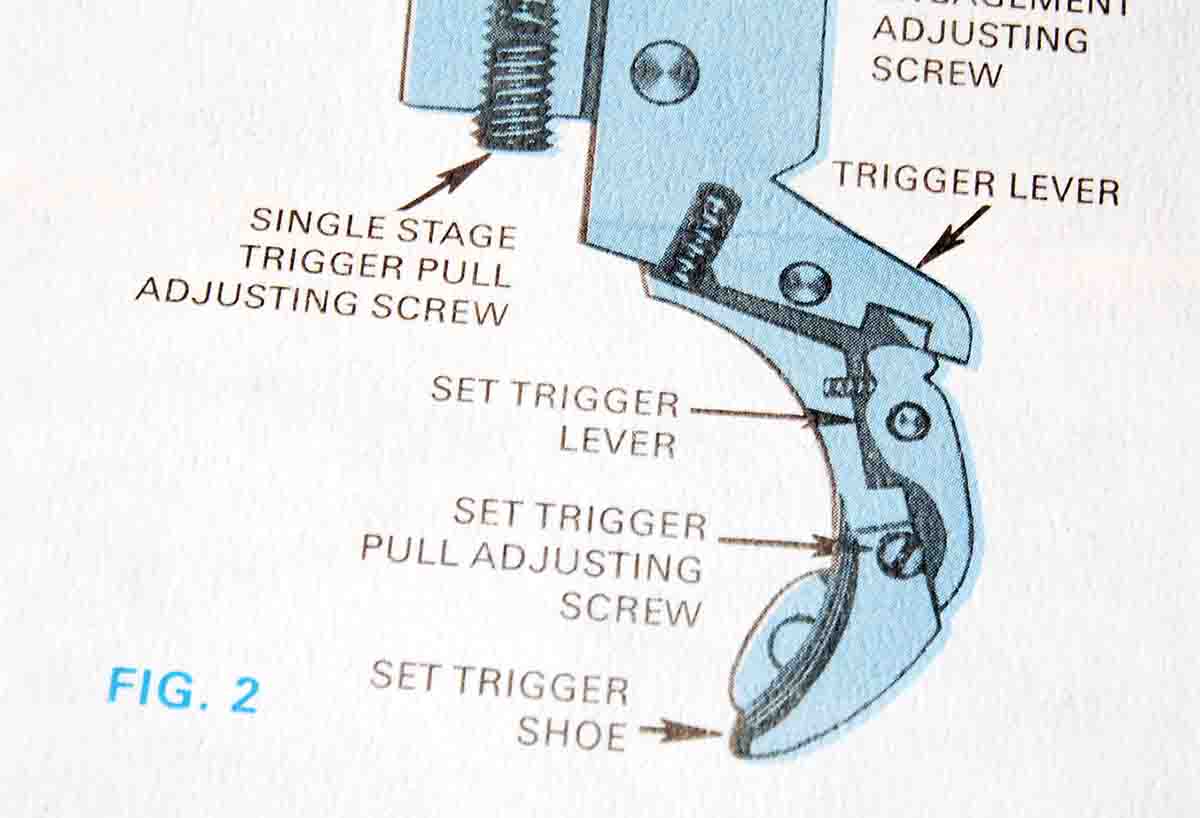

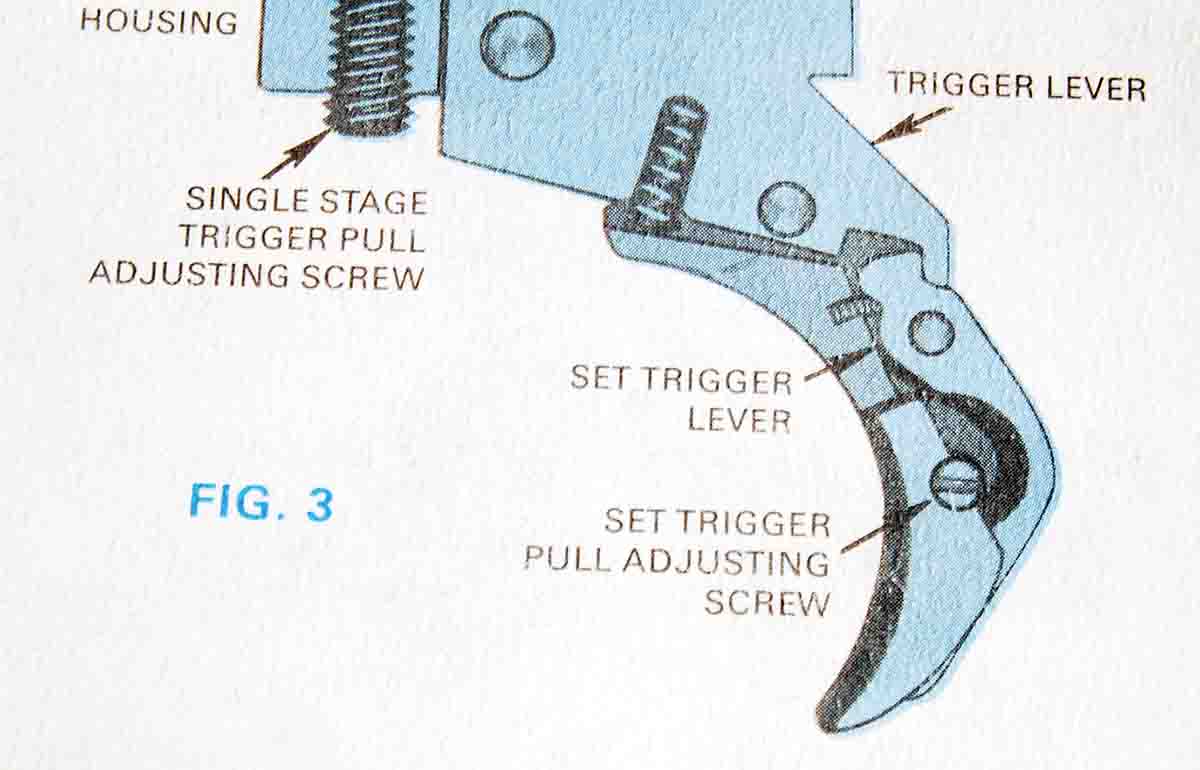

The reason for covering the Canjar non-set triggers is because their set trigger involves only the addition of a set trigger shoe in place of the normal curved finger piece. When unset, the trigger looks like one fitted with a clamp on, half-inch wide trigger shoe so popular at the time. A closer look shows that the curved finger piece has been removed and the shoe is attached by a single cross pin. In the front of the shoe a thin, vertical slot has been milled.

To set this trigger, a fingernail is hooked behind the shoe and pushed forward until the set trigger lever protrudes from the slot in the front of the shoe. There is no sound produced when the trigger sets. Touching the small, exposed piece releases the shoe, which snaps back with enough force to jar the sear out of engagement and fire the rifle.

The only problem I have seen with a Canjar set trigger is dirt or gun case lint getting into the mechanism because it is exposed outside the stock. Simple cleaning as described in the last column corrects this. Other complaints were just what you would expect – set trigger pull was too heavy. When newly installed, I always set the trigger to release at just under one pound. Nevertheless, more than one owner wanted the set trigger to release when the side of the stock was rapped with the knuckles!

Photos show a Canjar set trigger installed on a Ruger No. 1 built with a very heavy 30-inch barrel as a Schüetzen-style cast bullet rifle. From a benchrest, there is no real difference in group size between an unset 2.5-pound pull and set 10-ounce let off. Offhand is a different story! The light pull cuts scores in half.

Sadly, except for muzzleloaders or a very few reproductions of old long-range rifles, newly made set triggers are a thing of the past. Yet with proper practice, they provided a delightful solution to a very real problem for competition riflefolk at the time. They are from an era when target shooting was a more leisurely pastime. Do not fear the set trigger. Just don’t disturb it so long as it functions properly, but clean if necessary – and never file, bend or disassemble one.