Reader Research

Barrel Motion Compensation

column By: Norman E. Johnson | September, 17

All barrels are subject to some degree of gravitational downward flex from breech to muzzle, however slight this may be. All barrels are lithe to some degree. Under high internal bore pressure, the barrel tends to straighten. The straightening effect is primarily vertical due to gravity and varies with bullet passage time, as well as the axial alignment of the barrel. Varying names and/or terms are often tagged to these phenomena, which may include “barrel whip,” “cycling,” “vibration,” “flexing,” “oscillation,” “dynamic motion,” etc. All result in vertical flexing or motion of the barrel with varying degrees of frequency. In any case, barrel motion can set the stage for unpredictable kinesis.

Method and precision of barrel attachment to the receiver also affects barrel movement, as does barrel and action bedding and general fit of parts that make up a rifle. The barrel joint also plays a critical part in top-grade accuracy. I have learned through extensive experimentation that the degree of barrel joint precision and barrel/receiver torque can have a favorable or untoward effect on barrel motion. Axial torque (axial preload) must fall within a “normal” range for best performance. This is affected by thread surface finish, receiver ring finish, thread pitch, barrel size, number of threads (tpi) and barrel thread/receiver ring lubricity. Bore condition can also be a factor. So, while proceeding with experiments in barrel motion compensation, I would minimize these aspects of the process.

Many different methods have been tried to lessen or control the effects of undesirable barrel movement or vibration. Relatively few methods have been totally successful. Most involve the use of some form of adjustable weight screwed on, or otherwise attached, to the barrel. In three cases, I monitored the result of barrel impact differences and accuracy following sleeving standard-weight barrels to target- and varmint-weights. The outcome was most interesting and clearly resulted in a measurable difference or improvement in accuracy and bullet impact.

Over the years, I learned of a few accounts where barrel-tuning devices were quite successful, then were negatively challenged as ineffective. I had experimented with different methods of barrel control, with varying effects on accuracy, as well as some experience with the Winchester/Browning Ballistic Optimizing Shooting System (BOSS) with mixed conclusions. The BOSS involves various “sweet-spot” settings of the muzzle-mounted device to optimize barrel vibration relative to caliber and bullet weight. I also noted an advertised unit made of a vibration controlling material that slips over the barrel. It was claimed to provide sub-minute of angle (MOA) groups for factory ammunition. I’ve not heard or read of further test results on this product or others.

When probing more deeply into barrel tuning, experimentation led to a different concept that would set it apart. I call it a barrel motion compensator (BMC). I had the necessary components to make the device and machined and fitted the rudimentary parts.

The basic BMC concept involves attachment of a parallel rod to the underside of a barrel using a special collar that can be positioned at any point beneath the barrel, forward of the stock, running parallel to the barrel. Unlike some barrel-tuning methods, this unit requires no threading or changes in barrel configuration. The free end of the rod is directed toward the muzzle. The rod is free of barrel contact beyond the barrel attachment. Two hexagonal-shaped sliding weights are attached to the parallel rod via centrally drilled holes through the flat underside of each weight. These movable “tuning weights” are locked into position with two threaded setscrews at the bottom flat of the weights. The sliding weights, albeit close, have no direct barrel contact at any point. I determined the required total weight of these two sliding weights to be 4 ounces (2.5 ounces and 1.5 ounces). Total weight of the attached BMC is 8 ounces, including the two adjustable weights, 55⁄8-inch rod and barrel attachment collar that was made from a modified medium height Redfield Jr. scope ring milled, drilled and tapped to solidly interface the main rod. Appropriate spacers machined of brass or nylon for precise, individual barrel fit are necessary. The BMC can be attached or removed in minutes.

The premise behind the attached sliding-weight bearing rod is to establish a means of secondary control or compensation of harmonic frequencies originating in the rifle barrel. I visualized this secondary shunting or diversion of cyclical harmonic waves as a positive barrel-dampening component – changing the balance point or moment of inertia.

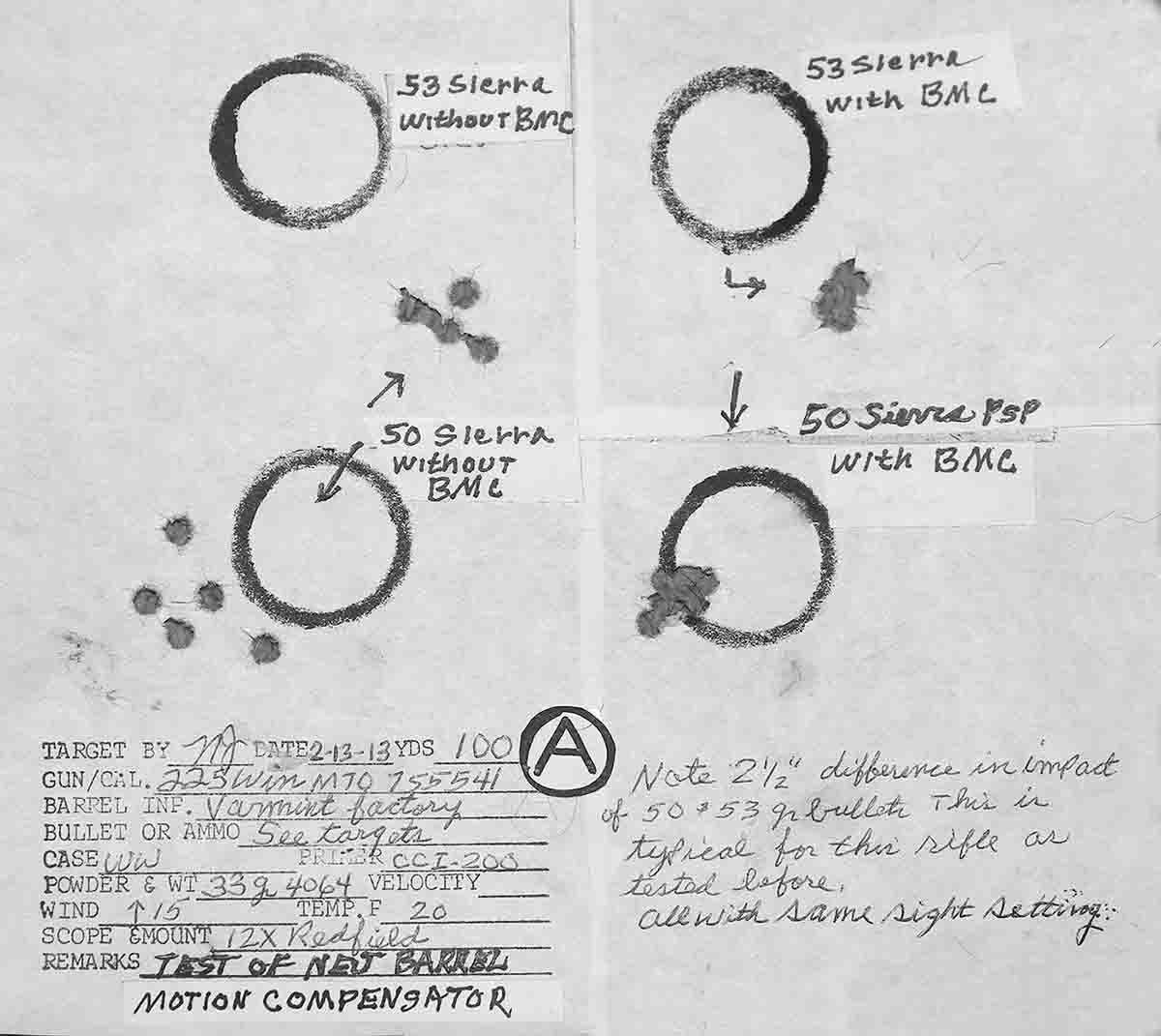

Rifle barrel vibration varies among rifles. Many rifles commonly shoot a wide range of bullets virtually into the same place on the target, while other similar rifles, with the same bullets and loads, may print tight groups that are widely separated, clearly demonstrating varying degrees of barrel movement on bullet exit. A typical example of this is my Model 70 Varmint .225 Winchester rifle that provides sub-half-minute accuracy. Two different loads containing Sierra 50- and 53-grain bullets ahead of 33 grains of IMR-4064 powder produced good groups at 100 yards, but the 53-grain group was diagonally higher by a full 2.5 inches. This variance was first discovered some 15 years ago and tested twice since that date with the same outcome. In later tests with the BMC in place, the improved accuracy attainable was encouraging. (See target “A”.)

The rifle was used for further tests both with and without the BMC. Sierra 50-grain BlitzKing bullets were used with 38 grains of Vihtavuori N540 powder and Federal 210 primers. This test included two groups at 100 yards. The targets show two groups averaging about an inch without the BMC and right around .5 inch with the BMC in position with both weights in the forward position. The remarkable thing here is how the groups with the BMC in place were 2.5 inches above those with it removed.

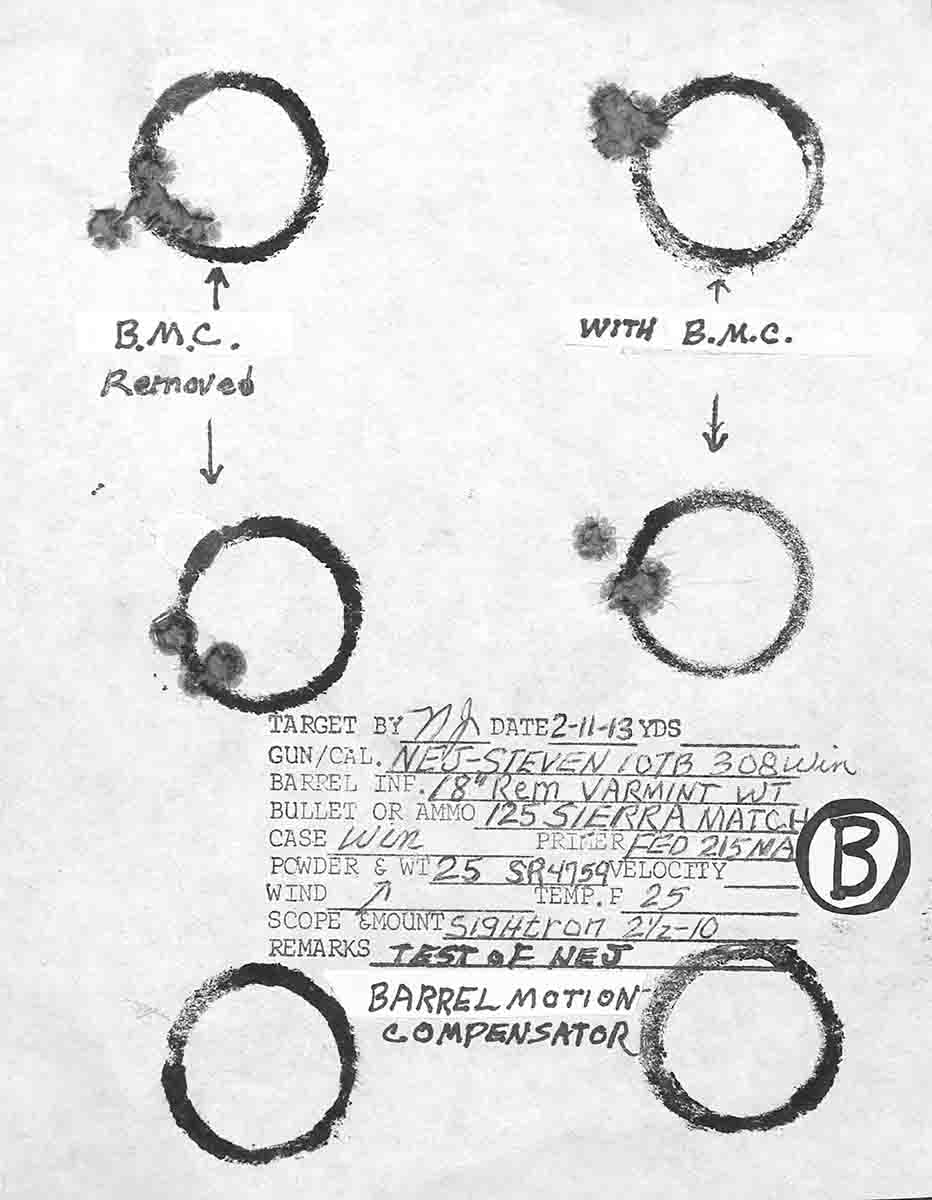

Extensive BMC tests were later conducted using a break-open, single-shot .308 Winchester. One reduced load in particular shot very well – a Sierra 125-grain Match bullet. Further tests were conducted with and without the BMC. The BMC worked well, as accuracy was markedly improved with the unit properly adjusted.

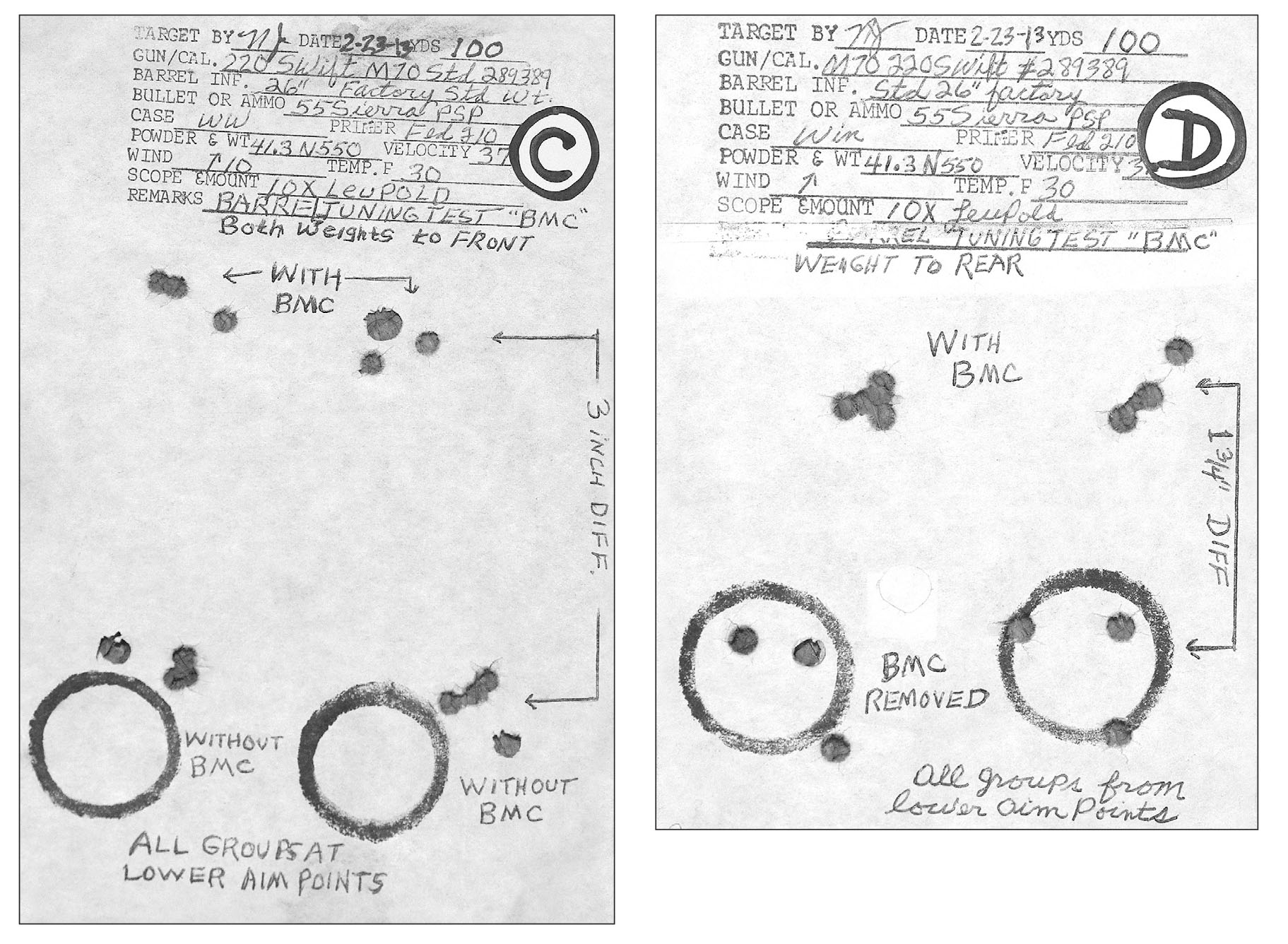

Another test involved a Model 70 Winchester .220 Swift with a standard 26-inch barrel. These cause-and-effect tests involved moving the sliding weights forward and back to locate the accuracy sweet spot. Two pairs of 100-yard aim points were used with the same rifle and load with both sliding weights to the front, and with the BMC removed. The test was then repeated with the sliding weight to the rear and with BMC removed. Bullet impact was 3 inches higher with the BMC installed and weights forward, as compared to 1.75 inches higher with the weights rearward. Groups with weights forward weresimilar, at around .6 MOA, whereas groups were markedly improved with the weights to the rear. Groups can be further tuned by changing the weight position on the suspended rod. All groups were shot using only the lower aim points on each of the two targets to allow for higher bullet impact resulting from the BMC. I have not experimented with how sliding weight variance or bar length may affect the BMC – which would likely introduce a measurable effect.

A separate, adjustable means of diverting or shunting barrel motion to a secondary moment appeared as having a very workable application. It is easy to construct and use, with a wide range of adjustment requiring only a basic knowledge of the principle used. I’ll not claim this to be the panacea for taming all rifle barrels, but as long as shooters remain interested and continue to learn, it makes it all worthwhile.