Lithgow Crossover Rimfire Rifle

Testing a New Australian Import

feature By: Stan Trzoniec | September, 17

In 40 years of testing guns, this is the first I’ve had in my hands that was made in Australia. Not that I shied away from any, but with the strictest gun-control laws in the world, frankly, there are comparatively few guns made down under. This one is a fine-tuned rifle from Lithgow Arms, a company manufacturing military-type arms since 1945. After World War II, it seemed the perfect time to design and build sporting rifles, so Lithgow embarked on the production of a set of rimfire rifles to include both a single shot and a repeater. Both were discontinued in the early 1970s.

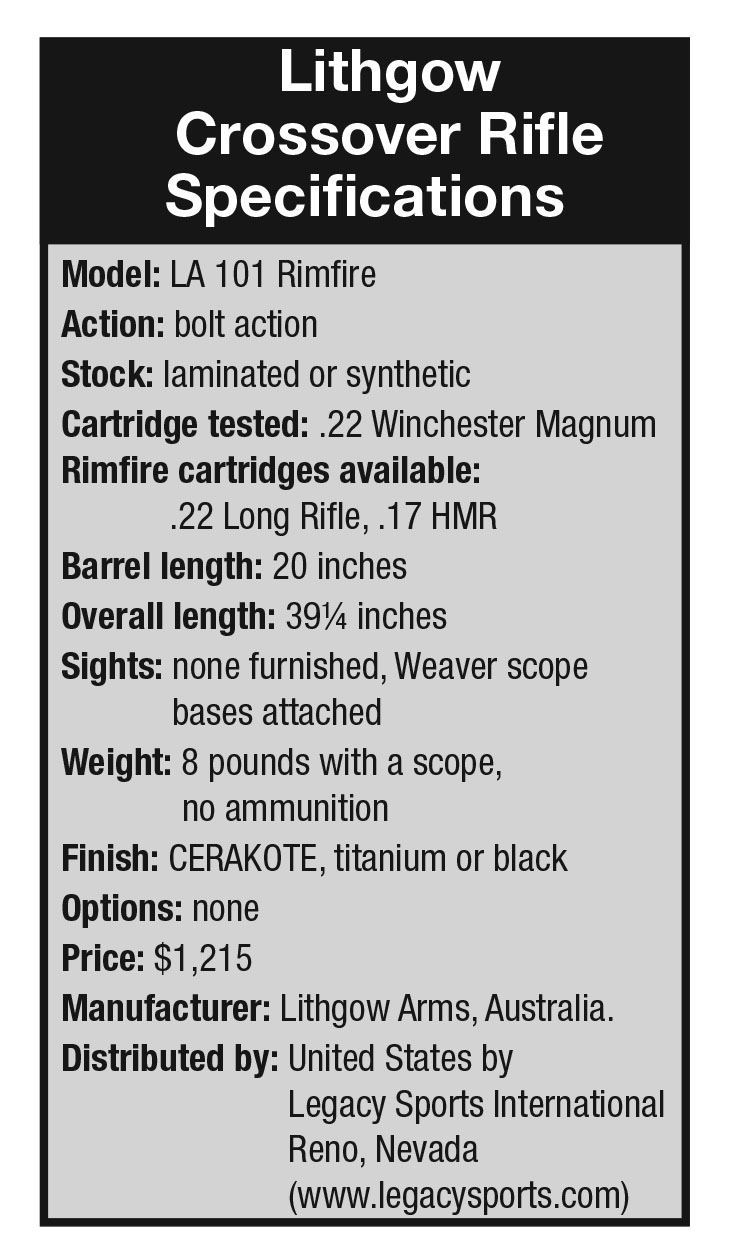

Apparently, a few were left for sportsmen to purchase, namely the Fieldman and Sportco models, but for the most part, they were discontinued in the 1980s, leaving the sportsmen of that country without a viable hunting rifle. This year, both a Lithgow rimfire and centerfire rifle were introduced at the SHOT Show, with the U.S. distributer being Legacy Sports International of Reno, Nevada. Rimfire cartridge options include the .22 LR, .22 Winchester Magnum Rimfire or .17 Hornady Magnum Rimfire. Choices for centerfire cartridges include .223 Remington, .243 Winchester or .308 Winchester with numerous options to include availability of both laminated and synthetic stock versions.

I was impressed enough with the lines, features and finish on the Crossover that I requested a .22 WMR. Looking at the overall appearance of the rifle, Lithgow combined many of the features that will please American sportsmen.

While this Crossover Model LA 101 is stocked in two different materials, the laminated stock was chosen for its looks, overall durability and comfort. The first thing I do with a new rifle is pick it up and mount it to my shoulder, to see how it fits to my stature. Since this rifle is made for the varmint shooter (more on that later), my left hand fit perfectly around the forearm and my right hand blended nicely to the finely shaped pistol grip.

Starting from the forend of the stock, it is carefully rounded so as not to catch on anything in the field. From this point rearward, the width of the forearm measures 2 inches; perfect for field use when you might have to employ an impromptu rest. The pistol grip was just right for prone shooting. The buttstock had a rather high comb, but after mounting a scope, my eye lined up with the reticle of the scope without any problems. Lithgow added a butt hook, but I’m withholding judgment until I have more time with the rifle in the field. While some hunters may think the stock is a radical new development, one look at Mossberg’s MVP Varmint series reveals a stock configuration similar to the one on the Crossover, sans a sizable butt hook. There is a substantial recoil pad on the gun – too much for a rimfire rifle – but obviously the stock is made to accommodate both rimfire and centerfire calibers. It is installed with very close tolerances and has a black spacer. The stock is finished off with sling swivel studs front and rear.

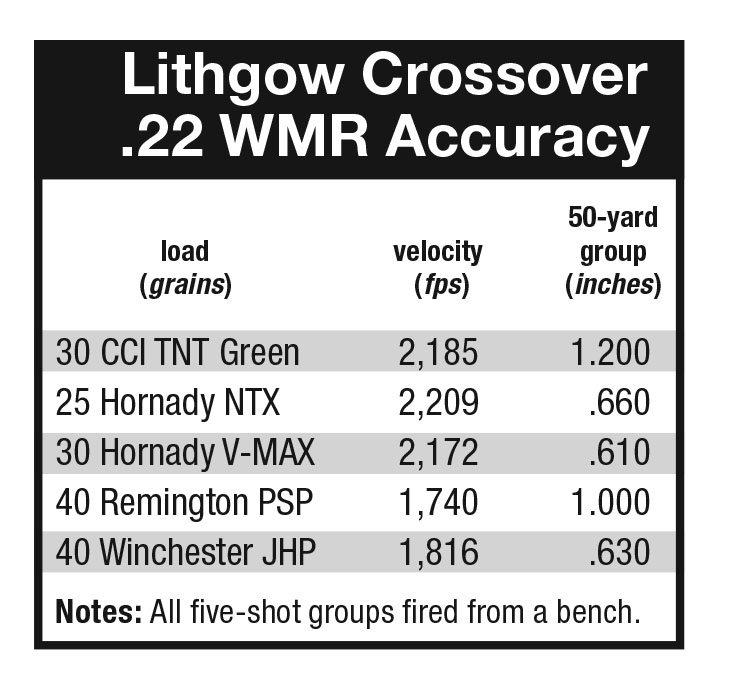

The action needs some detailed description: Since the rifle is made to be a semi-target or varmint rig, the action, barrel and related parts are satin-finished with a CERAKOTE H-series titanium coloring. The barrel is rather interesting, because it is only 20 inches long, a length I find ideal for both the .22 LR and .22 WMR cartridges. It is cold hammer forged, button broached and threaded into the receiver. It included an 11-degree target crown with a match chamber that, according to Lithgow, has been machined to tighter tolerances than required by conventional SAAMI specifications, and it comes with a 1:16 twist. There is a machined cap on the muzzle that, when removed, can accommodate barrel accessories and tapers from .985 inch at the receiver to .690 inch at the muzzle – a medium-weight sporter barrel. No fixed sights are furnished, but the rifle comes with Weaver-type mounts on the receiver, and for the best in accuracy, the barrel is free floated and bedded at four points within the barrel channel.

The receiver is modern in all respects and rather compact. It is fully machined from high-tensile steel and is 5.75 inches long with an outside diameter of 1.180 inches (30mm). For design purposes, or perhaps to save a little weight, the left side of the receiver has been scalloped out and shows the Lithgow proof mark; the distributor and the company logo are etched into the side. The right side also has one scalloped panel proclaiming that it is “Australian Made.” The ejection port is nicely machined into a modified oval to allow both easy loading and ejection of cartridges.

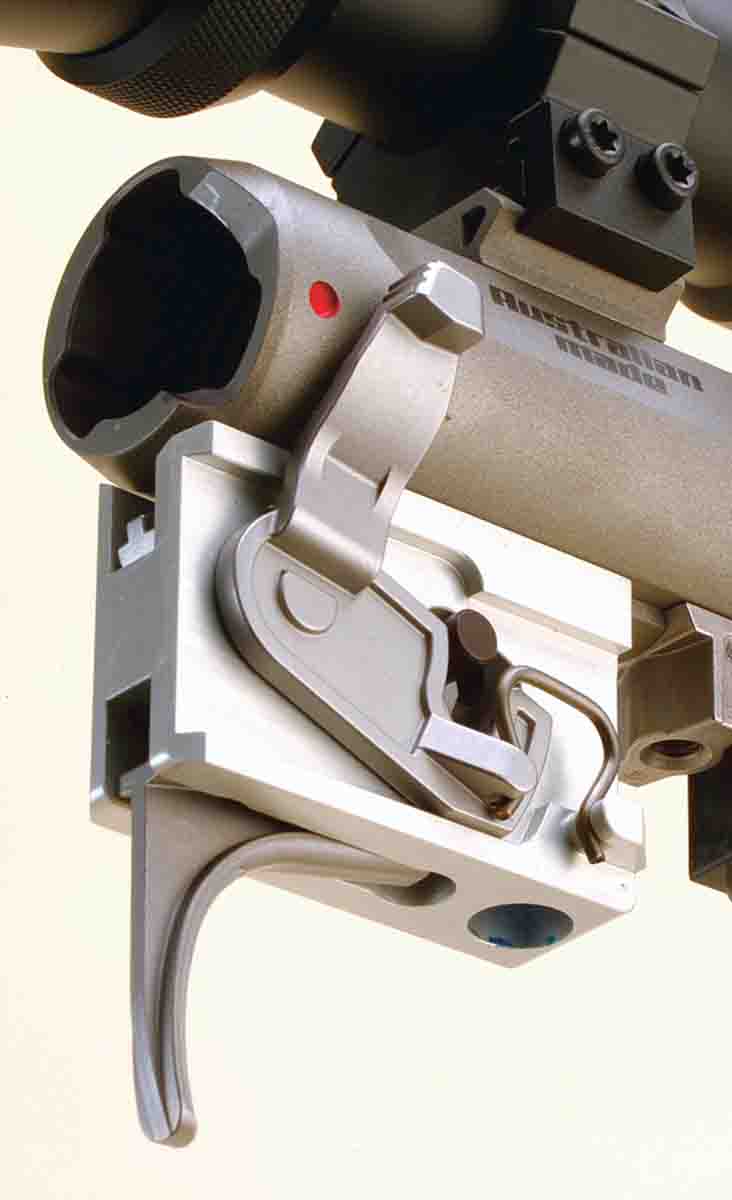

Gunmaking is becoming more innovative each year, and looking at the bottom of the receiver shows why. It is machined flat and has an integral lug running full length from the barrel/receiver junction to where the bolt shroud would start. Lithgow has made this unique 5-inch lug to “hang” various components on, like the magazine well, internal recoil lug and the trigger assembly, for a precise, wobble-free fit.

From the barrel rearward, there is the front stock screw, then the polymer magazine held securely via twin Torx screws. Behind that is a recoil lug that fits snugly into the stock and holds the rear stock screw. Following that, a stainless trigger mechanism is set in an alloy housing and is complete with a two-position safety lever that locks firmly in each position, courtesy of a large U-shaped spring on the outside of the assembly. A red dot on the side of the receiver shows the safety is “off” and is matched by a red dot on the bolt body showing the action is cocked. The trigger is nonadjustable and on the test rifle broke at 2¾ pounds without a hint of take-up. The trigger, magazine well and floorplate are housed in a polymer assembly that fits snugly into the stock. There is a polymer box magazine, or clip, that holds five rounds of single-stacked .22 WMR ammunition.

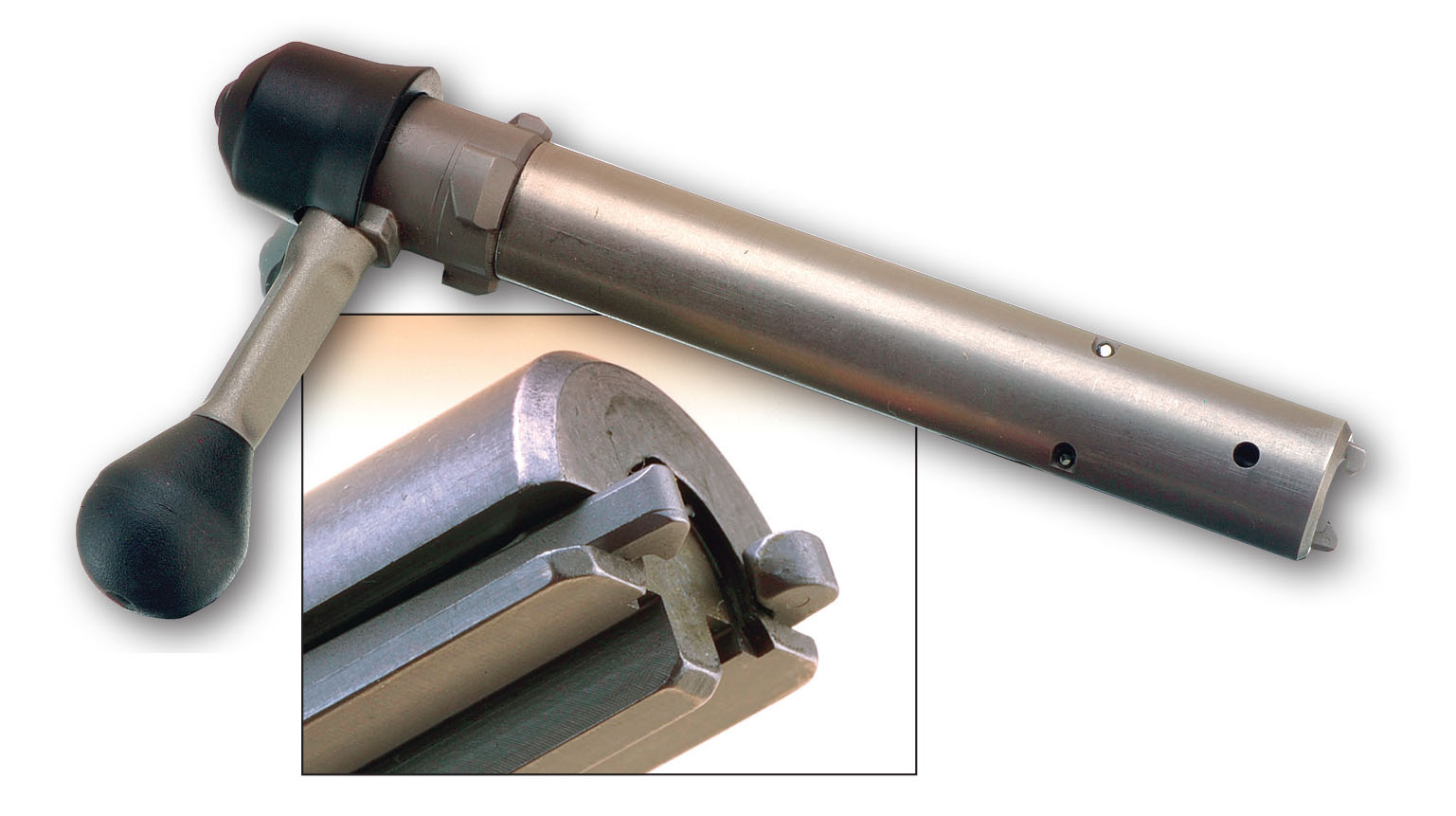

To release the bolt from the unloaded receiver, push the safety lever into the “fire” position, then pull back on the trigger while backing out the bolt. When removing the bolt, I found that some extra rearward pressure was needed on the trigger for the sear, which also acts as a bolt stop, to clear a horizontal slot in the bottom of the bolt. Like the rest of the rifle, the bolt and its components are finely machined.

The bolt includes three locking lugs at the rear. The lugs are tapered inward, allowing for smoother operation while still giving a shorter 60-degree lift. This three-lug assembly gives more support and strength over the more common rimfire method of locking the bolt via the bolt handle going into a recess in the stock. The bolt body is smooth, enhancing operation. Up front is a recessed bolt face with heavy extractors pinned to each side of the bolt. At twelve o’clock is the firing pin; opposite that is a bottom ridge to push a new cartridge into the breech. The bolt body is very substantial and, measuring 1.80 inches, is sure to add stability that leads to better accuracy. The bolt handle has a triangular form to it. There is a small dimple at the end, denoting the bolt is made only for the .17 HMR and .22 WMR rifles. Finally, a plastic shroud compliments the end of the bolt.

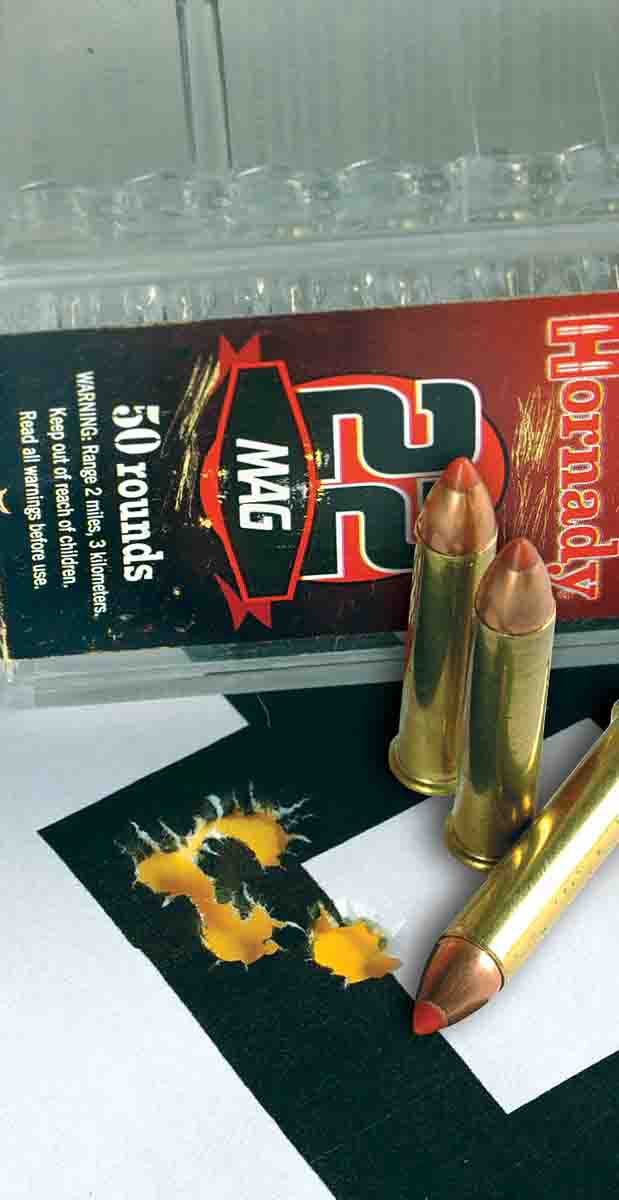

Taking the rifle apart reveals interesting design features within the confines of the stock. The bottom recoil lug mates with a slot within the stock, and up front, the receiver is held tightly against the stock via the front stock screw. There are long and short recesses within the forearm. Stock inletting is sharp.The .22 Winchester Magnum Rimfire cartridge was introduced in 1959. I first shot the cartridge from a Ruger single-action revolver. Later, the purchase of a Winchester Model 9422 proved the WMR was even better in a rifle.

Okay, some criticism is coming: First, the hook in the stock kept getting in the way when using sandbags. Pushing the rear bag back to drop the muzzle and get on target turned out to be a nuisance; just when I was almost at the horizontal line on the target, that bump really moved the reticle down on the paper. This rifle otherwise has the makings of a fine firearm. The lines of the action are nice, the overall finish and fit is very good, and the trigger is great without any need for adjustment. However, if the stock was profiled in a more classic pattern with possibly a cheekpiece, Lithgow would have a hard time keeping up with production.

Operation was fine, and the more I shot it, the more the rifle settled down. For example, when I got to the range and started sighting in, upon loading the magazine, the second round would pop up at the feed ramp with the case rim sticking up. With a small stick that was lying next to the bench, I pushed up and down on the follower over a dozen times. After that, everything settled down, and feeding and ejection went smoothly.

Overall, the Lithgow Crossover has some innovative features that set it apart from other rifles. The test sample was accurate, the action was smooth and it was just nice to have it in my hands for testing and photography.