One Good Shot

Mauser's Model 1871

feature By: Art Merrill | January, 25

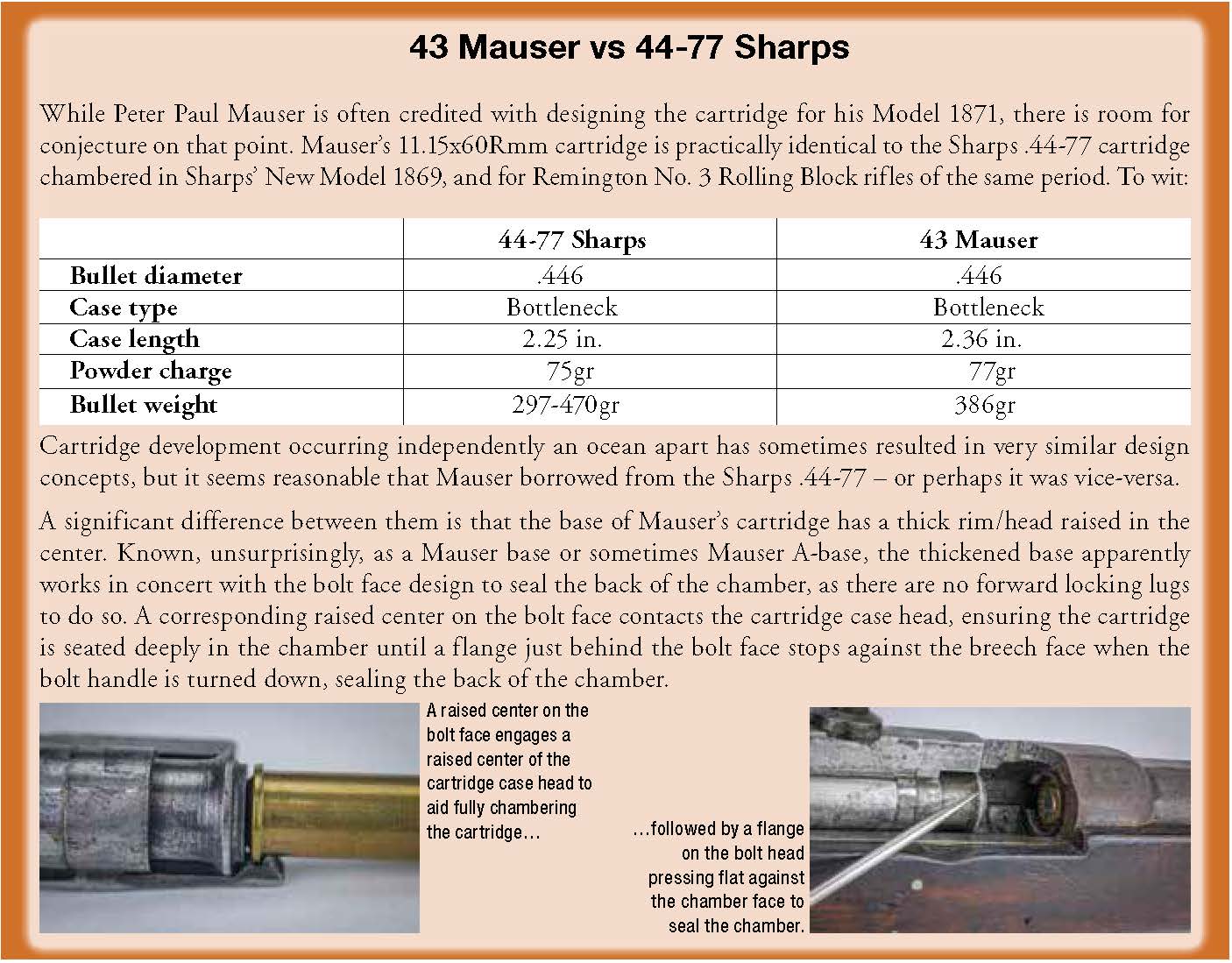

That success began rather inauspiciously, as it turned out. About 1866, the Mausers failed to garner any interest in their first rifle, a needle gun based on the design of American Eduard Lindner. In a world still dabbling with the final incarnation of the self-contained metallic cartridge, their next design, chambering a new black powder 11.15x60Rmm metallic cartridge, caught the attention of Prussia. Though the Prussian Rifle Testing Commission adopted the Mauser design after trials in 1871, Prussia built the rifles in their own arsenals and paid Peter Paul and Wilhelm Mauser 8,000 Thalers – about $6,000 – for the rights. For the time being, the Mausers had to make do with manufacturing only sights for the rifles. Their luck changed when the German state of Wuerttemberg contracted Mauser to manufacture 100,000 Model 71s, which it did from 1874 to 1878. The company also made 26,000 export rifles for China. Though the fortune of Mauser Brothers and Co. continued to rise and fall, the bolt-action, cartridge rifle was here to stay.

What avid rifleman wouldn’t want a specimen of the world’s first successful bolt-action rifle? Model 71s were made in such numbers (approximately 3,000,000) by Mauser and the government arsenals at Amberg, Danzig, Erfurt, Spandau and by Steyr in Austria (Austrian Arms Co.) that many survive. According to Ludwig Olson (Mauser Bolt Rifles, F. Brownell & Son, 1976), other manufacturers include cooperatives Spangenberg & Sauer, Schilling, and Haenel in Germany, and English companies Greenwood & Batley, Ltd and National Arms & Ammunition Company. Model 71 buyers included China, Honduras, Japan, Transvaal and Uruguay. Model 71s served in combat, reserve and paramilitary capacities around the world at least as late as 1918, and milsurps converted into 12 guage and 16 guage shotguns were still being sold in the 1930s.

The M71 is not a strong action, though strong enough for its black powder loadings. Made of “wrought steel,” the metal lacks nickel to strengthen it; nickel steel didn’t appear in small arms until about 1895. The back of the M71’s bolt guide rib serves as the only locking lug as it braces against the right receiver wall on closing the bolt; it bears virtually all the force of the backward thrust of the cartridge on a single surface area half the size of your thumbnail. The bolt head and bolt body are separate pieces. There is no provision to vent gasses in case of a ruptured primer or case failure. A slot cut in the left receiver wall accommodates the extractor as it moves with the bolt, and gasses escaping along this slot might be partially deflected away from the shooter’s face by a small shield on the left side of the back of the bolt – a forerunner of the shield found on the Model 1898 Mauser. The “wing” safety also carried over onto the Model 98. There is no ejector, ejection being accomplished by tipping the rifle to the right and allowing the case to fall out from under the extractor.

![“Bavarian 11th Ersatz [Replacement or Reserve] Infantry Battalion, Company 3, rifle number 38” appears on the butt plate, which is missing a screw.](https://www.riflemagazine.com/Media/Articles/2025 Issues/1 Jan-Feb/AM-07.jpg)

The trigger guard is brass; the barrel and receiver have such patina as to appear to have been browned, making reading the ciphers and acceptance marks a challenge. The one-piece wooden stock has enough dings to account for at least one war but happily exhibits no cracks, splits, or deep gouges. The receiver serial number is stamped into the barrel channel, and “No. 2” cartouches appear on the stock in two places.

Related or coincidental to the stock cartouches, a large numeral “2” surmounts two asterisks on the receiver.

Ciphers in Fraktur – old German font – identify who manufactured or inspected any particular M71 in Imperial Germany, but I have yet to find an English language resource that matches Fraktur ciphers to specific manufacturing facilities or inspectors. I had better luck deciphering the “B11RE338” stamped into the butt plate, which apparently translates as, “Bavarian 11th Ersatz [Replacement or Reserve] Infantry Battalion, Company 3, rifle number 38.”

Manufacture date on the receiver is 1877. Serial numbers match on stock, receiver, bolt, barrel, barrel bands, butt plate and screw heads, showing the rifle is original insofar as not being cobbled together from several “parts guns,” and offering some additional confidence in being a safe shooter.

The “10,95” stamped on the barrel indicates the measured width across the bore lands at the time of the stamping, so the bore is apparently considerably eroded. Still, it’s worth the experiment to see if the old war horse can still shoot. Now, what about some ammunition for this great-great-grandpa?

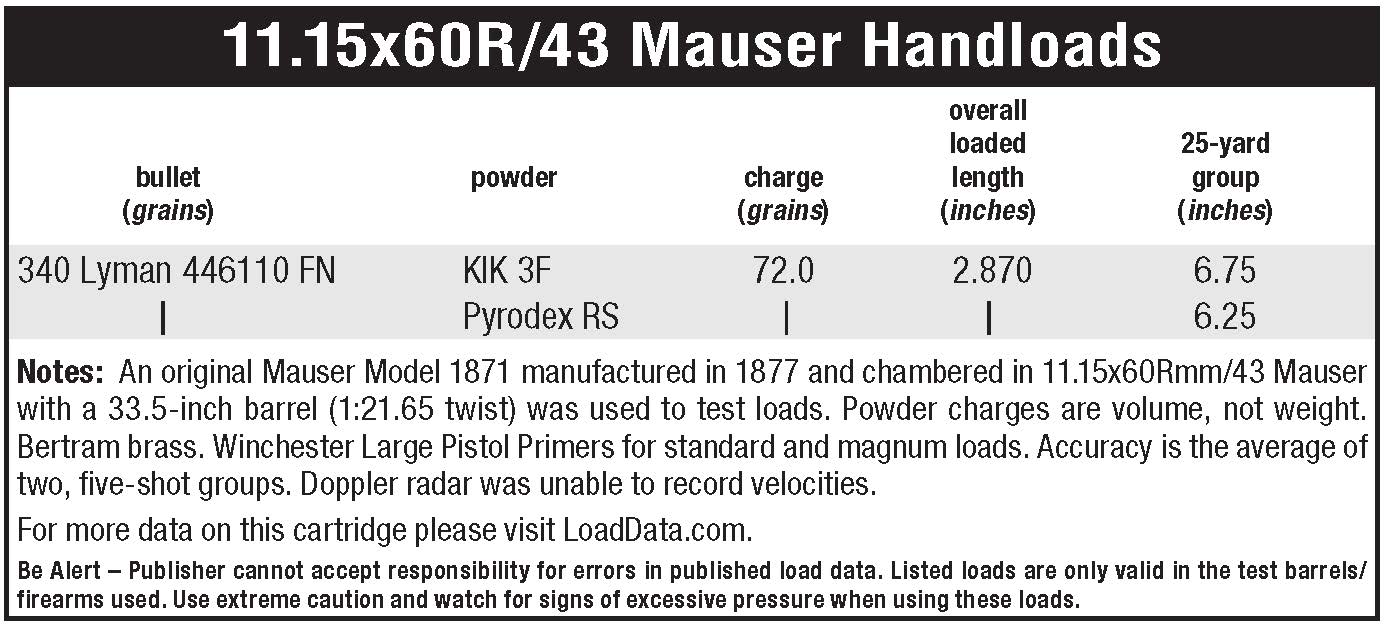

I acquired a box of 20 43 Mauser handloads built on properly headstamped Bertram brass and broke them down to use the brass for my own loads. For load data, Olson and several other sources list a black powder charge of 77 grains with bullets weighing 370 to 386 grains.

The first problem with this particular M71 evidenced itself when test firing a primed, empty case: it didn’t happen, the firing pin only leaving a very slight dent in the primer. One well-known fault with Peter Paul’s M71 design was its weak ignition, which Mauser resolved by loading softer primers in the ammunition. The problem here is perhaps exacerbated by a 150-year-old firing pin spring further weakened with age.

My modern solution was to substitute Large Pistol primers for the Large Rifle primers. I must emphasize here for the neophyte that in general practice, handloaders should not use pistol primers in cartridges intended to be fired in rifles, as pistol primer cups are thinner than rifle primers. Rifle firing pins typically strike with more force than do handgun strikers and hammers, and they could pierce a pistol primer. In the case of this specific M71, however, we already know of its weak ignition proclivity, and my solution worked.

The lack of accuracy may be due to a mismatch between rifling and bullet. Recall that the original Model 71 cartridge utilized a roundnose, paper patched bullet, and so it had comparatively shallow rifling to accommodate. The .466-inch FN bullet here is intended instead for the rifling in the later Model 71/84 repeating rifle shooting “naked” lubricated bullets. For more on this subject, see The Paper Jacket by Paul Matthews, available from Wolfe Publishing (WolfeOutdoorSports.com).

More load development and custom bullets for paper patching would likely shrink groups, but further pursuit of the matter is a subject more appropriate for Handloader magazine. Here, we conclude with this example of the world’s first truly successful bolt action rifle that can at least produce a single accurate cold-bore shot.