Light Gunsmithing

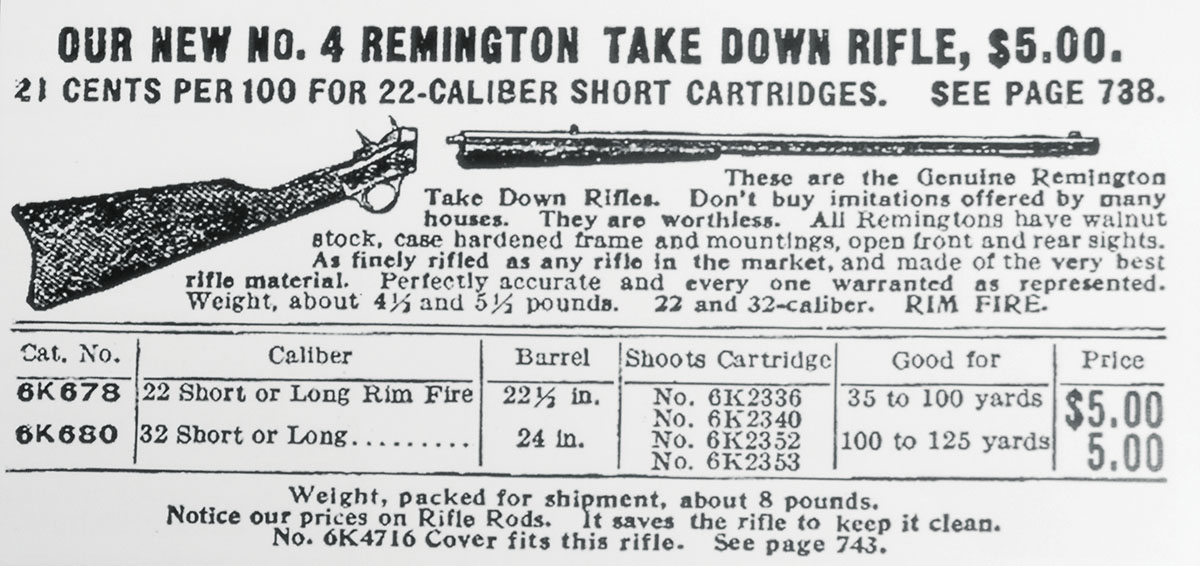

Remington No. 4 Boys' Rifle and the Ammunition

column By: Gil Sengel | January, 25

A low selling price was always the main feature of these little rifles. Thus, costs were minimized to the extreme by ingeniously simple designs. However, this desire for ever simpler and cheaper manufacturing led to safety concerns that today would cause a company lawyer to abandon his practice and take up dog grooming.

Early 22 rimfire ammunition had cases drawn from copper. Copper is soft. Case rims often blew out at the point of impact with the firing pin tip. Some of the old single shots (that were not bolt actions) had chambers without rim recesses; the entire rim was exposed between the rear of the barrel and the breech face. Cost was the reason. It is far faster and cheaper to make a straight-sided reamer than one with a step up at the rear to cut a rim recess. While rim blow-outs are rare today in brass cased ammunition, they still occur. When shooting the old rifles eye protection is mandatory.

It is also sometimes written that boys’ rifles are dangerous to fire with modern high-velocity cartridges. The inference is that these rounds are loaded to a higher pressure than others.

However, my latest data shows all long rifle cartridges (standard velocity, match, high velocity and hyper velocity) have the same Maximum Average Pressure (MAP) of 24,000 psi. This figure is not inconsequential as the MAP for the 38 Special is 17,000 psi and 45 ACP is 21,000 psi. Ammunition companies don’t have to load up to the limit. Standard velocity and some match ammo are probably lower since it doesn’t function in many autoloaders. Standard velocity rounds will often be the most accurate, anyway.

Unfortunately, the No. 4 is not without its faults. The first is most important when buying one of the rifles. Pull the hammer back to full cock with the breechblock closed. There should be a gap of about .035-inch between the rear of the breechblock and the front of the hammer. This gives enough

The fix is a new trigger since the trigger and sear are one piece. Given that the last No. 4 was made over ninety years ago, good luck with that. Such guns are best left for someone else to own.

When a joint won’t tighten up it’s best to turn a new tapered pin on the lathe and cut a few threads to protrude from the receiver on the small end. Cut no takedown flat on the pin. Make a round nut with a screwdriver slot to fit the threads, tap in the pin, and pull the nut tight. Never touch it again!

The only reason to use a takedown feature today is because a cleaning rod contacts the hammer nose when cleaning from the breech. This will not happen if the gap between the hammer and breechblock mentioned a few paragraphs back exists. If not quite enough, pull the hammer back past full cock and insert a shim (See photo above), fit, and the breechblock to hold it there. It’s not very elegant, but it prevents disturbing the takedown joint or cleaning from the muzzle.

Mainsprings are simple flat springs that should not break. A broken spring would probably indicate excessive dry firing so look carefully for abuse. A damaged firing pin is also easily replaced.

Receivers are forged steel so the tang can usually be bent back into place without breaking -- once! Then the metal cracks at the bend. Repairs have been seen in the form of gobs of brazing or silver solder alloy on the tang and even attempts with a common arc welder that melted much of the tang.

Proper repair is really quite simple, using a TIG welder or even a small wire welder with inert gas shielding.

Almost no gunshops have such equipment, but custom ‘smiths do. If repairing a broken tang, I would definitely have a lower tang welded on since a new stock will be required anyway. This makes the stock/receiver joint feel more solid. Finding someone to do the welding should not be difficult.

The gun in the photos was purchased as a well-worn rifle with a tang repaired by brazing, a broken stock and loose takedown joint. The top tang was replaced, a bottom tang was welded on, and a loose takedown joint was repaired using a solid pin. The rifle was then restocked and engraved. One does not mind spending a bit on an action like the Rem. No. 4. The same is true of the other No. 4 shown, which is an excellent example of 1960s custom work. It also had a takedown joint that required repair.