New Marlin Lever Actions

Production is Underway in Ilion, New York.

feature By: Brian Pearce | January, 17

Although new production rifles share the same design as previous models, they are built using the latest CNC tooling, with much of the handwork associated with previous production methods having been largely eliminated. Marlin has been steadily improving quality and function while offering variants that are in high demand. For the purposes of this article, two Model 1895s and one Model 1894 were obtained for testing and evaluation, which produced some interesting results.

The Marlin lever pivots from a single screw, which minimizes travel. This allows speed when cycling the action with the gun held at the shoulder and is one of several reasons Marlin rifles are so popular among cowboy action competitors. With a screwdriver, the lever screw can be quickly removed – with the action halfway open – and the lever pulled downward, followed by removing the bolt assembly out the rear of the receiver. This feature not only allows easy access to the action for cleaning but also permits the barrel to be cleaned from its breech, with both features being an advantage when compared to most other lever-action

The Model 1893 evolved into the Model 93, 36 and 336 that we know today. A modified 336 receiver became the basis for the Model 1895 introduced in 1972 to include the .44 Magnum, .444 Marlin, .375 Winchester, .450 Marlin, .356 and .307 Winchesters, .308 and .338 Marlin Expresses and other cartridges, and is the same rifle in production today. The list of cartridges this receiver has been chambered for is rather long; however, the .30-30 Winchester has been the most popular.

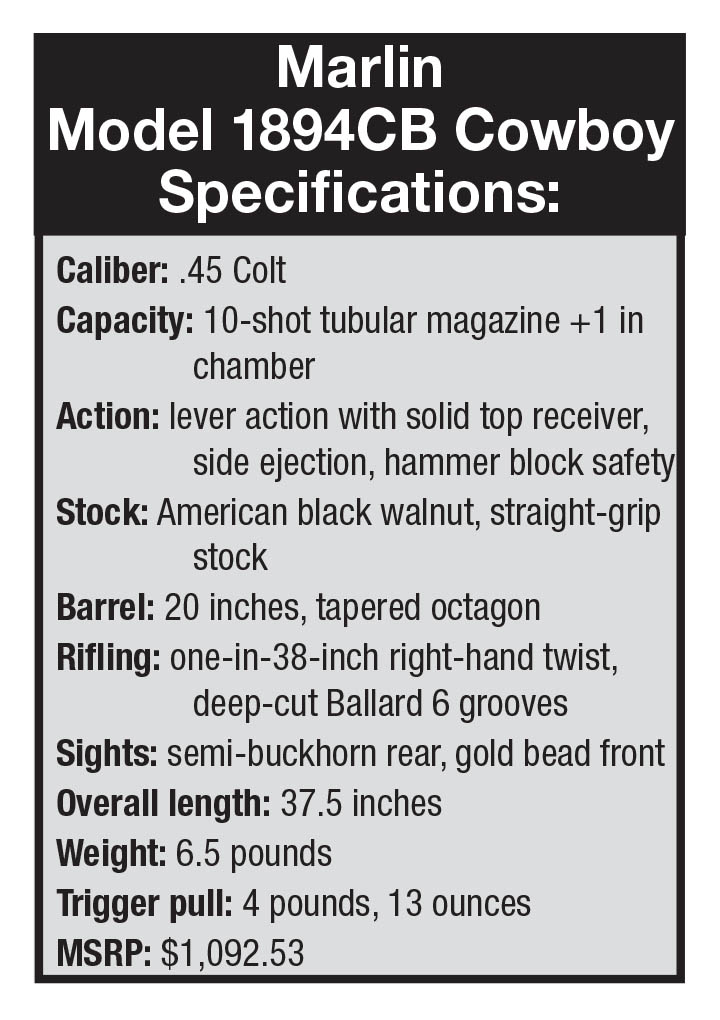

The original Model 1894 was discontinued in 1934 due to limited interest in the aging cartridges for which it was chambered, such as the .25-20, .32-20, .38-40, .44-40 Marlins, aka WCFs, but it was also a financial move due to dismal sales experienced during the Great Depression. After development of the popular .357 and .44 Magnum sixgun cartridges, many gunsmiths began converting rifles to these cartridges, so Marlin responded by introducing the Model 1894 in .44 Magnum in 1969 and .357 Magnum in 1979. Sales were extremely strong.

The decision was made to rewrite blueprints and corresponding computer programs and to purchase new CNC tooling, which took considerable time. The first fully manufactured rifles in New York were Model 336s. I have tested two, which shot well and functioned reliably, but there were some areas that needed improvement.

For the purposes of this article, three Marlin leverguns were obtained – a Model

The receiver, trigger plate, hammer, locking bolt and lever are all still manufactured from forgings, features that helped Marlin build a reputation of strength, longevity and reliability. The carriers are machined from solid bar stock steel, which has helped eliminate some of the variables associated with forgings; the tolerances of this critical part can now be held at much tighter specifications. (Incidentally, prior to 1978 Marlin leverguns featured a machined carrier.)

There are a couple of areas that could be improved. The trigger pull of all three rifles was rather heavy at just less than 5 pounds and would be easy to correct with CNC tooling. The forearm fit was tight on all three guns with no detectable movement and is an improvement. Unfortunately, the forearms of the 1895CB and 1894CB were rather blunt on each end, rather than being beveled down to meet the receiver and forend cap, respectively, while the 1895LTD forearm was beveled correctly.

The sides of the finger levers on both Model 1895s featured rather sharp edges, while the 1894CB (produced a few months later) was much improved. The hammers on all three rifles had comparatively sharp edges, and I would encourage Marlin to round and shape them closer to the originals, which will make them considerably more comfortable during long shooting sessions. While all three rifles fed and ejected cases reliably, I would like to see the timing changed to eject fired cases slightly farther from the action. In spite of the above comments, I am impressed with the overall quality and machining of the new Marlin rifles.

For accuracy testing, the Model 1895LTD and 1894CB were fitted with Skinner aperture rear sights, while the 1895CB was fitted with an XS aperture rear. Both are excellent sights that are fully adjustable for windage and elevation. They aid accurate shooting under a variety of lighting conditions and are durable and well machined. The brass Skinner Express sight installed on the 1895LTD complimented the gold highlights of that rifle.

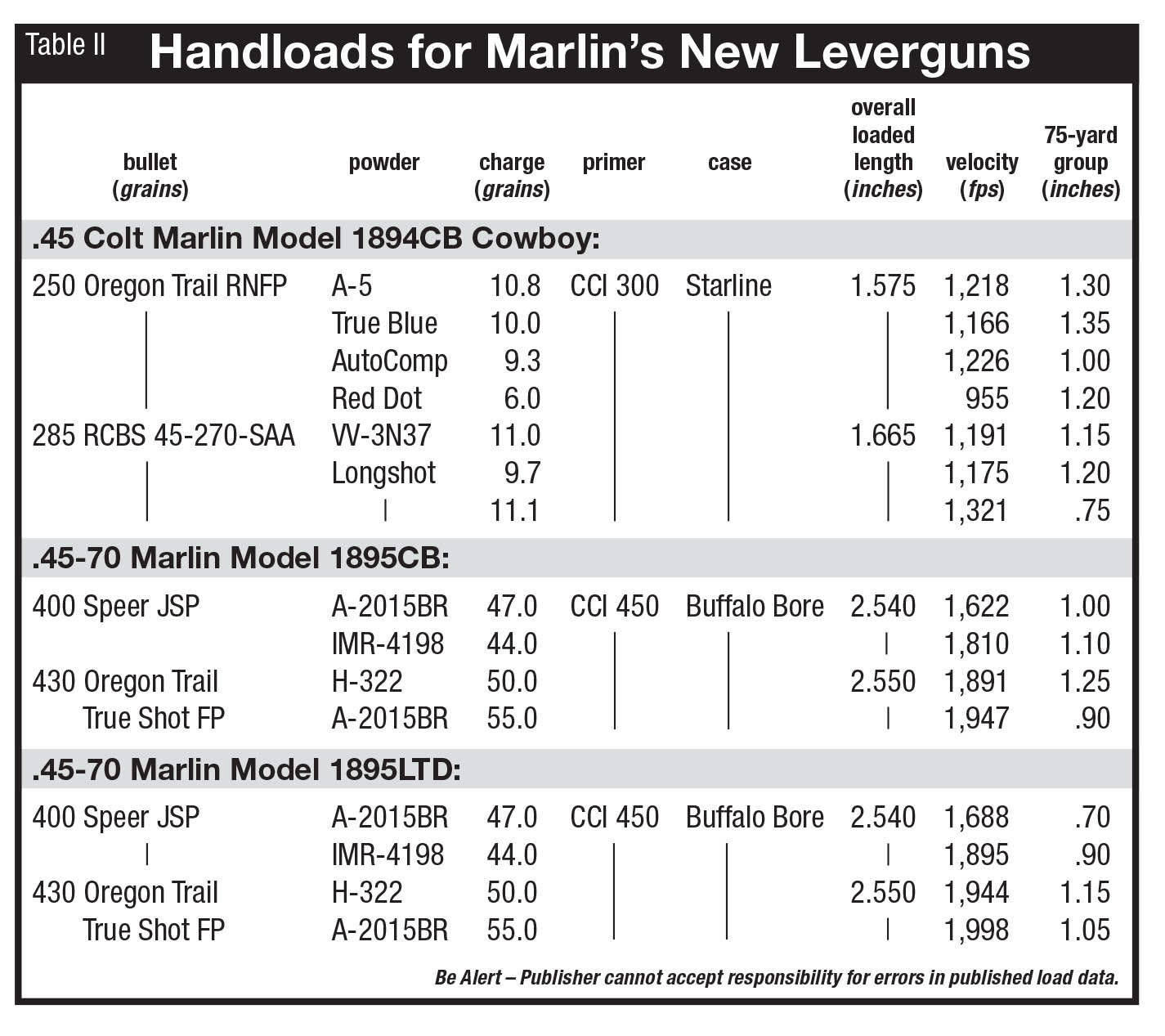

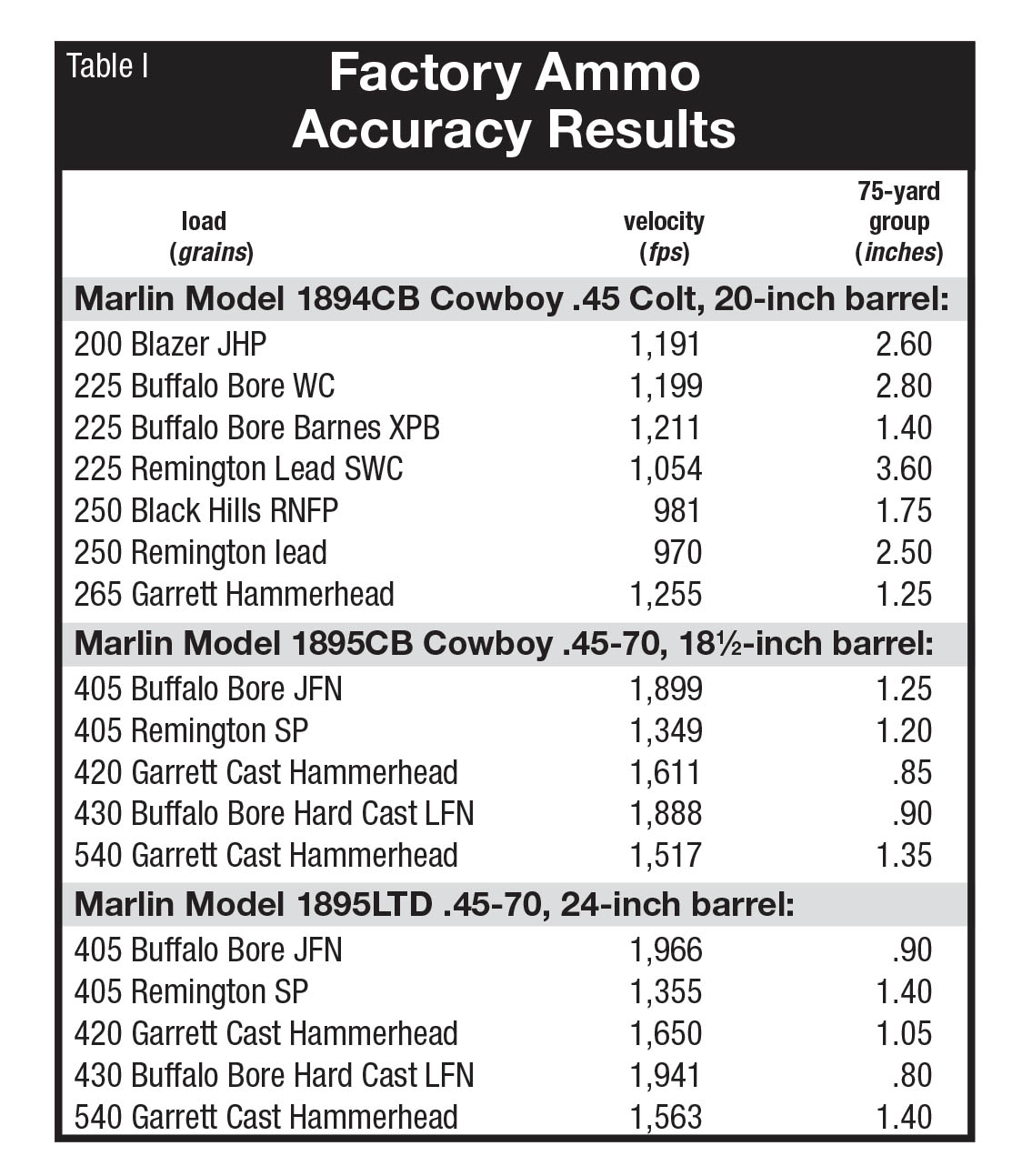

More than 1,000 rounds were fired in the Model 1894CB .45 Colt, and feeding and function were reliable with a variety of loads; however, when using Blazer 200-grain JHP loads, cases had a tendency to fail to eject, due to their extremely light weight. When the lever was worked enthusiastically, cases would then clear the action without issue. A variety of bullet profiles were tried for function, and the rifle easily fed cartridges with an overall cartridge length up to 1.665 inches (and will probably accept longer cartridges), including SWC or Keith profile bullets.

With the aid of a sandbag rest and with my left hand positioned solidly between the forearm and the sandbags, four-shot

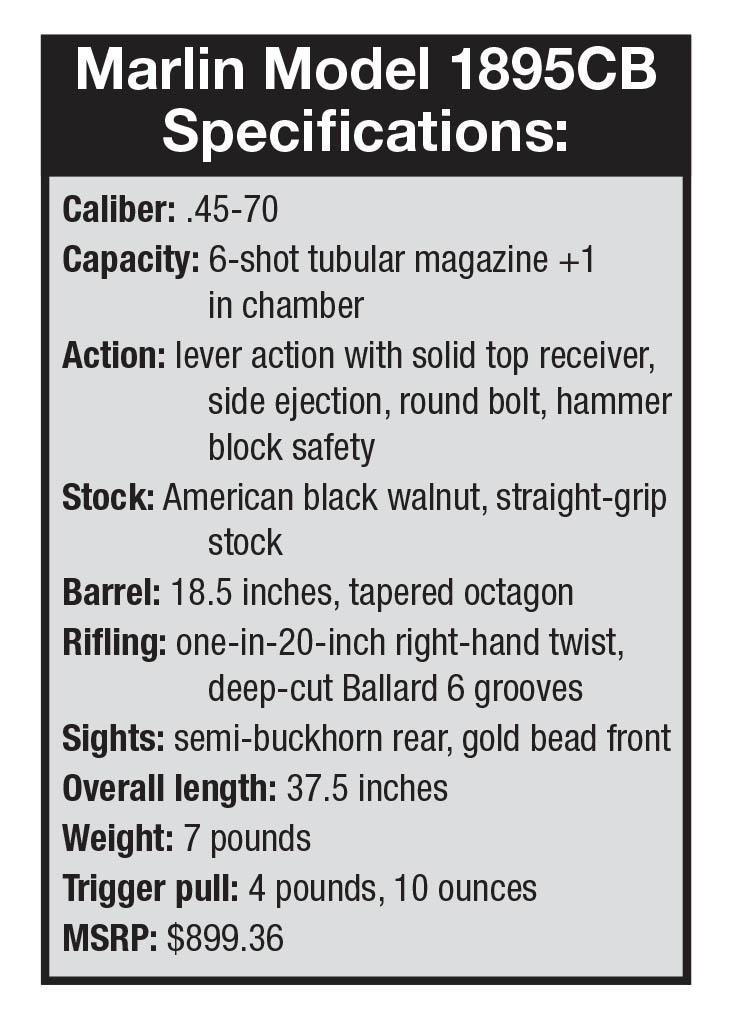

The Model 1895CB .45-70 shares the same overall length as the popular Marlin Guide Gun. With its 18.5-inch octagonal barrel and full-length tubular magazine it holds six (+1) cartridges. At 7 pounds, it will find favor with horsemen, guides or those who want a compact, lightweight and powerful package. From the bench it regularly clustered four shots inside one inch at 75 yards using a variety of factory and handloads containing both cast and jacketed bullets. Although it was not tested at 100 yards, all indicators are that it is capable of sub-MOA accuracy.

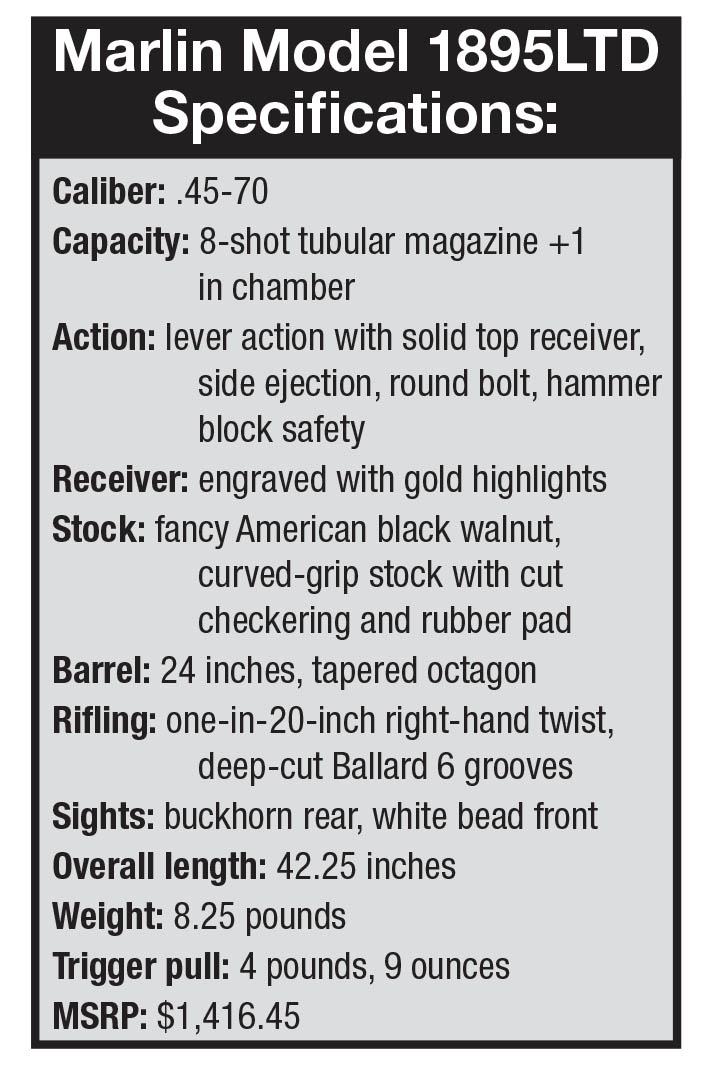

The Model 1895LTD .45-70 features an upgraded, figured American black walnut stock with gloss finish and checkering, curved pistol grip and 24-inch, tapered, octagonal barrel with full-length magazine tube. The receiver is machine engraved in an attractive, vintage scroll pattern and features 24-karat gold highlights of an elk (left side) and Marlin horse and rider (right side). The rear sight is full

The 1895LTD likewise proved accurate with several groups clustering under one inch, but it was slightly more sensitive to the individual loads used than its short-barreled counterpart. Its single tightest group at 75 yards was a handload that consisted of a Speer 400-grain JSP bullet pushed with 47.0 grains of Accurate 2015BR powder for 1,688 fps, which measured .70 inch. Subsequent efforts to duplicate that group resulted in others that hovered around one inch, which is still impressive for an aperture-sighted levergun!

Since setting up manufacturing in New York, Marlin has addressed and corrected many problems. In spite of these latest rifles having a couple of areas that I would like to see improved, the fact is they are quality rifles that shoot very well and are still manufactured 100 percent in the U.S.A.