Remington scaled up the Model 581 bolt (top) to make its Model 788 centerfire bolt (bottom).

The chronicles tell us that in the late 1950s, the decision-makers at Remington decided it was time to replace its popular Model 510 through 521 series of 22 rimfire rifles. One of the reasons for this was that production costs had become too high. Another was that Remington wanted to produce a 22 rimfire magnum and the current action was not considered strong enough.

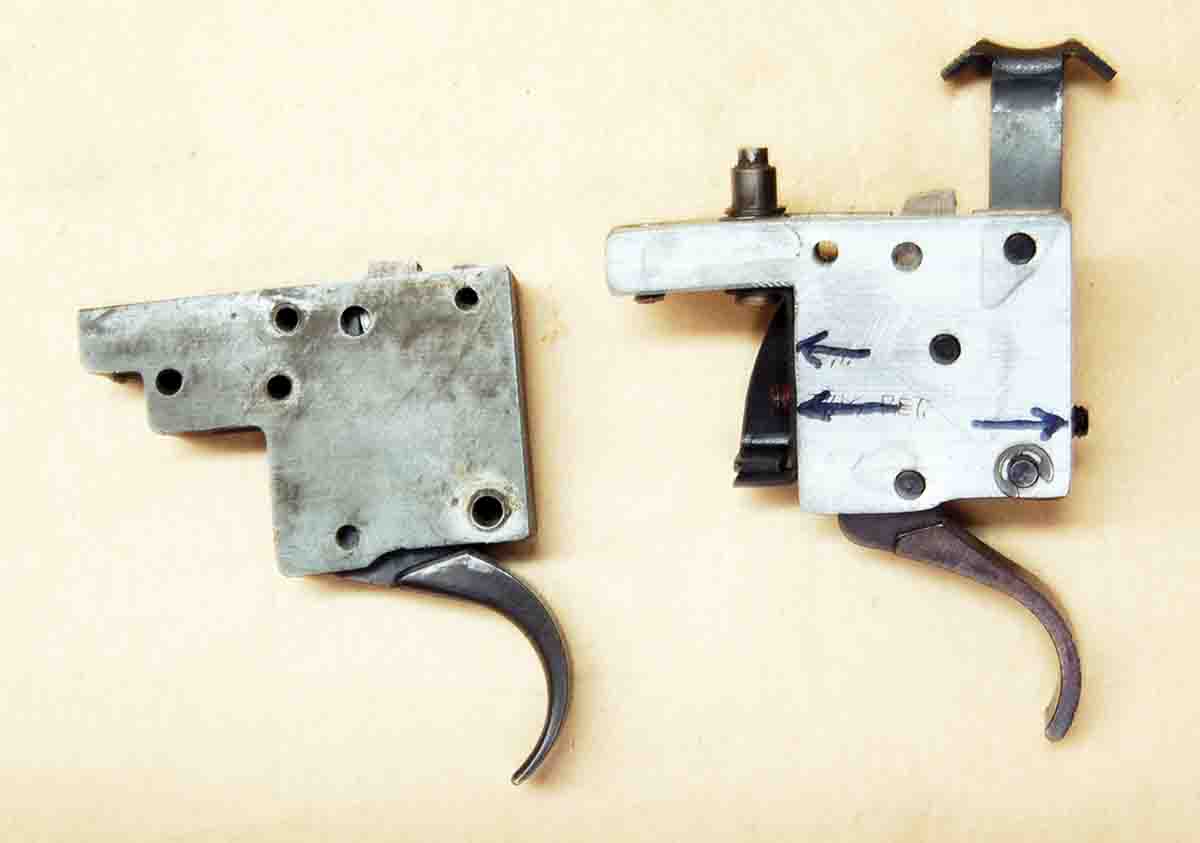

The arrow on the Model 541 target rifle (top) shows the firing-pin extension that engages the rear half of the bolt body, preventing misalignment when reinstalling the bolt in the receiver. Models 580, 581 and 582 don’t have this desirable feature for some reason.

In January 1967, Remington announced the introduction of the Model 580 single shot, Model 581 clip-fed and Model 582 with tubular magazine. At least five target models were also eventually available. A novel feature of the new actions was the method of lock-up. Three banks of shallow lugs, two per bank, were spaced 60 degrees apart on the rear half of a normal rimfire two-piece bolt body. The walls of the receiver were quite thick (.2 inch) to accommodate this feature. It was far stronger than needed for a 22 magnum rimfire.

The spring steel clip (see arrow) reinforces the feed rails of the Model 581 magazine. However, rounds still pop out and the magazine is plastic.

One would have thought Remington had a real winner here. However, the buying public thought otherwise. Before being dropped, sales of the Model 580, 581 and 582 barely reached 20 percent of the previous Model 510, 511 and 512 rifles. The total of all five of the new target guns was only 16 percent of the number of just Model 513-T rifles sold. There were reasons for this. Three of them we can deal with and two we can’t, so I will cover the first two.

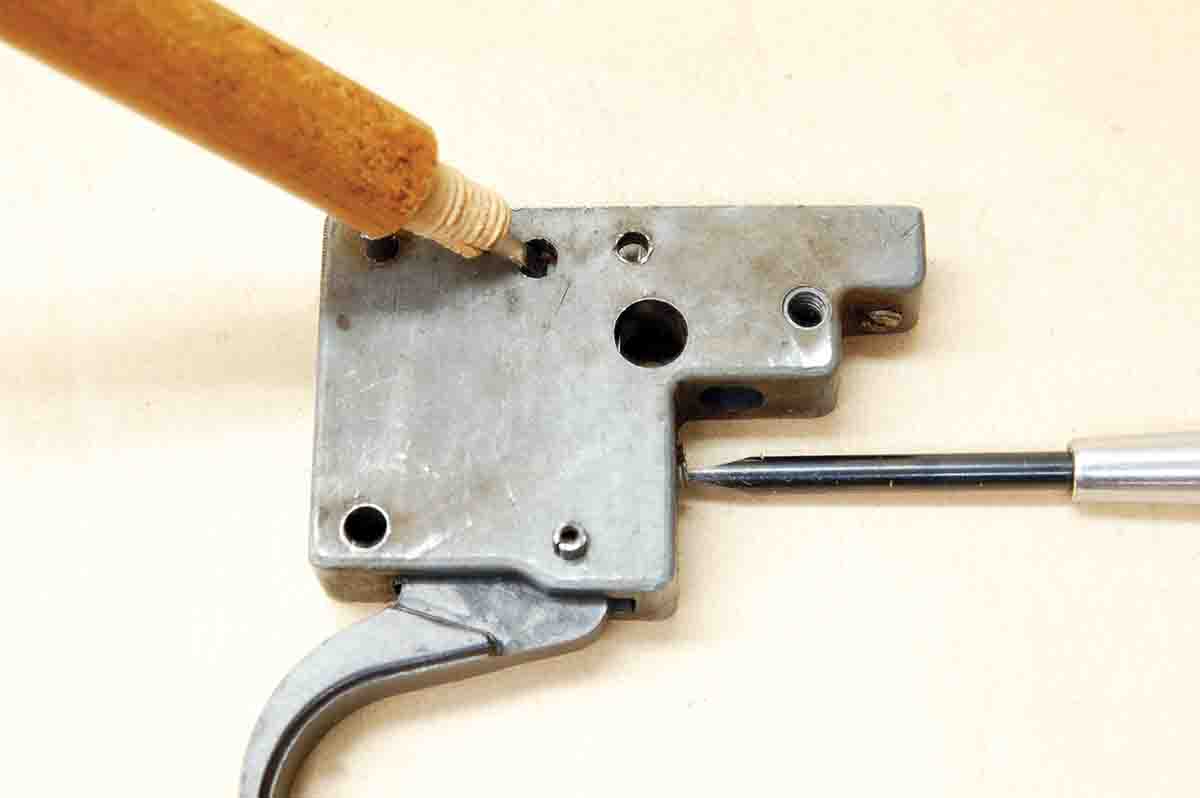

The firing pin should move freely. Pushing with a scribe point will tell if it doesn’t, disassemble and clean the slot.

Detachable box magazines (clips), if cheaply made, will all cause feeding problems if used very much. The magazine used in the Model 581 and the target rifles on that action were made of plastic, which is not a very good choice for rifles designed with kids in mind. Cracked magazine bodies happened and caused failures to feed. A tab protruding from the rear of the magazine to engage the magazine latch sometimes broke off. Also, rather common was pulling back on the bolt and having the rounds in the magazine squirt up into the receiver, causing a magnificent jam. A piece of spring steel encircles the top rear of the clip to reinforce the feed rails, apparently to prevent this. Apparently, it didn’t. Factory magazines are no longer available so the only option is an internet search.

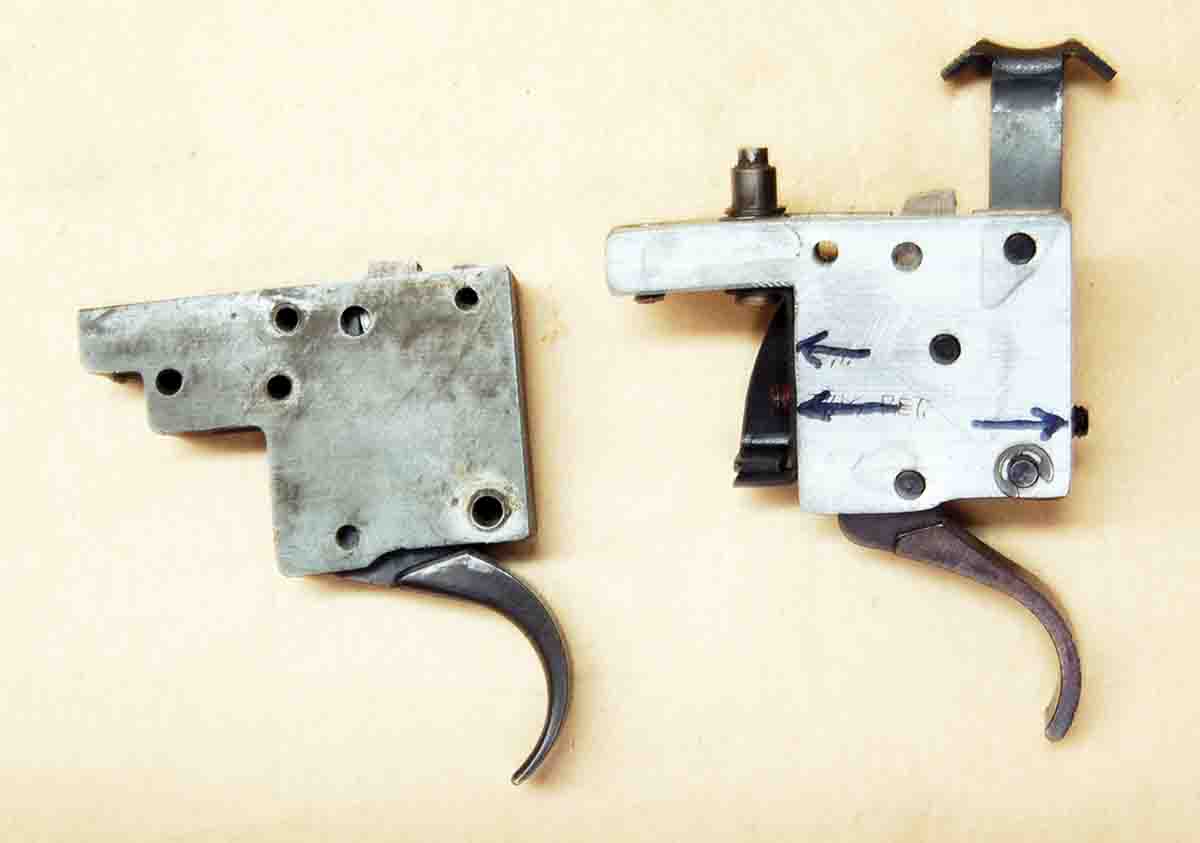

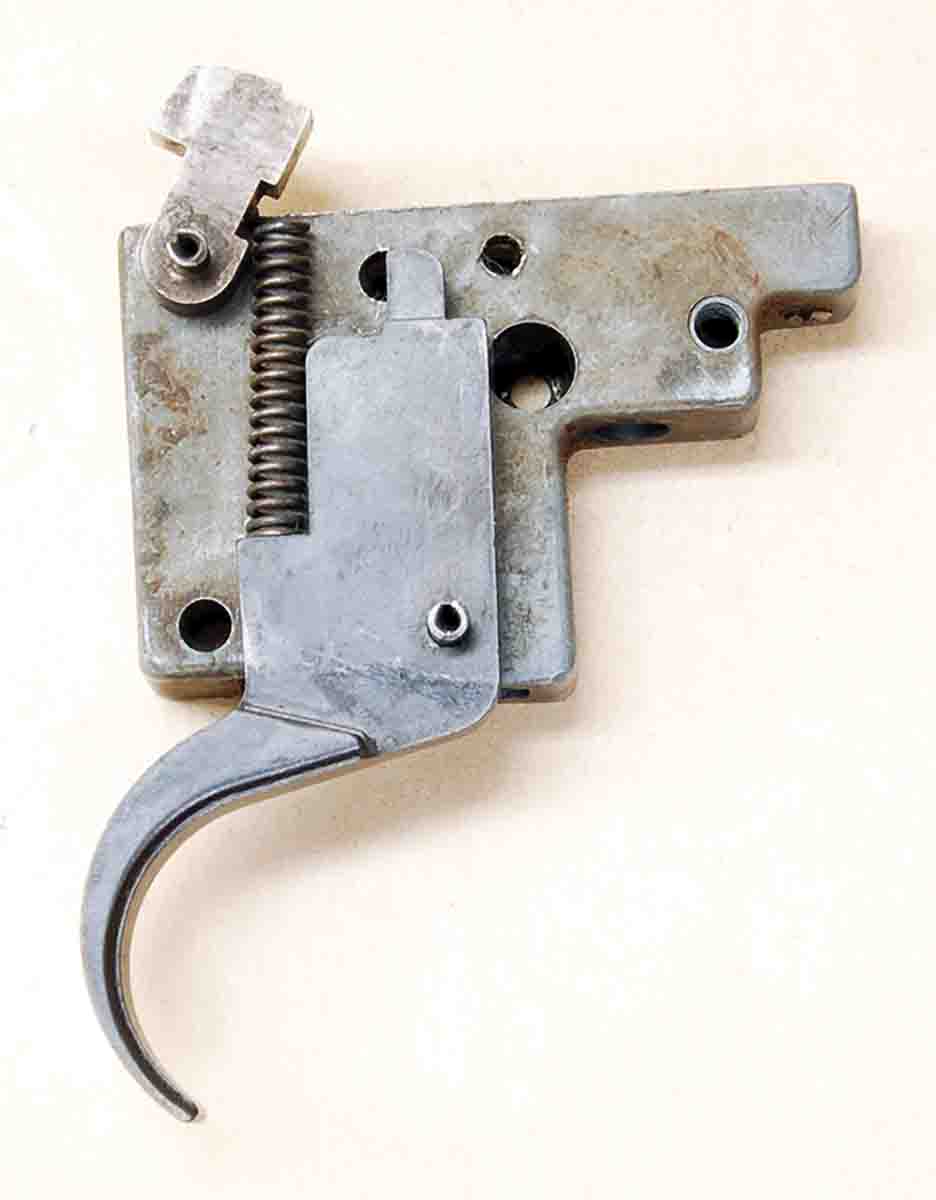

The Model 541-T trigger (right) has screw adjustments that are shown by the arrows. Models 580, 581 and 582 triggers (left) have none. I will correct this where needed.

The other design flaw is that there is nothing to prevent the front half of the bolt body from turning out of alignment with the rear half when the bolt is removed from the receiver of the Model 580, 581 and 582.

Replacing the bolt requires one hand to hold the gun, a second hand to hold the bolt, a third hand to hold the bolt stop down and a fourth hand to align the front half of the bolt. It is impossible for a youngster – and many adults – to do without assistance.

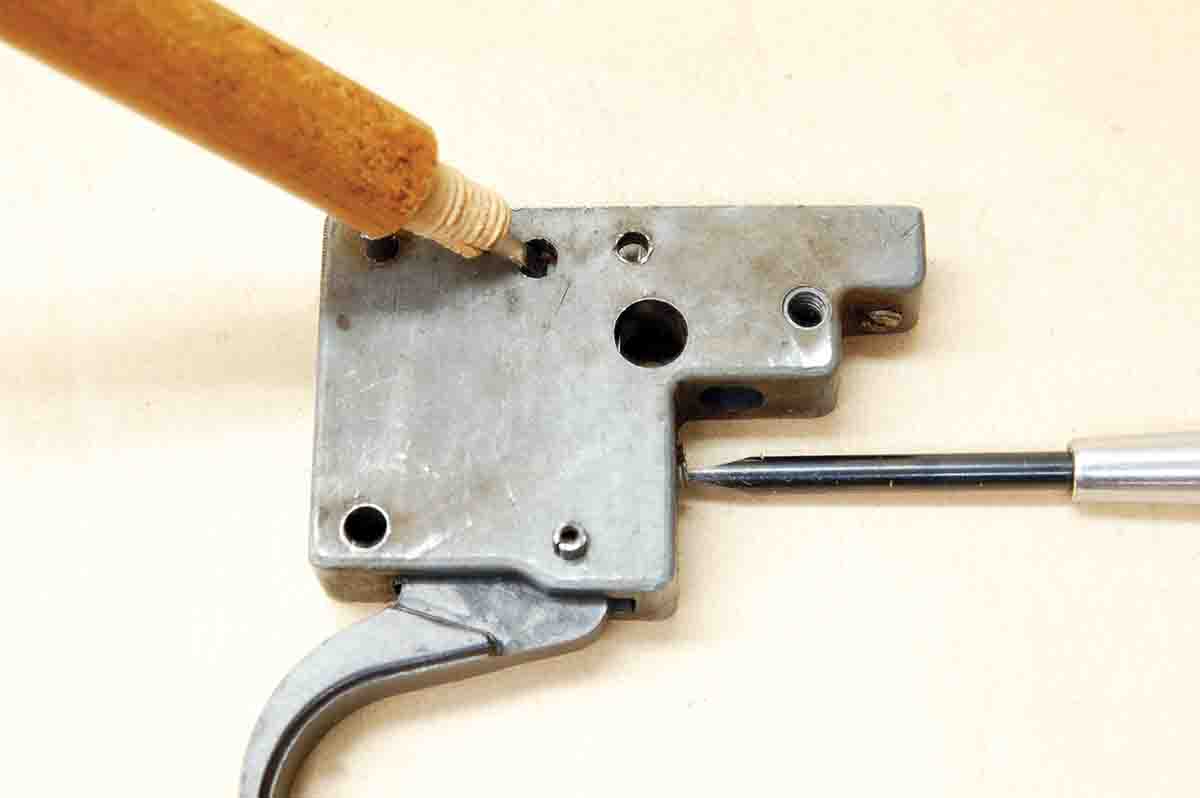

The bolt is disassembled by driving out one pin. Clean-firing the pin slot with a tool like the dental pick shown.

The target rifles on this action have a differently shaped firing pin, where a tiny spring pushes into a notch in the rear bolt half (see photo). Problem solved. It would have cost only a few cents to add this to the other models. We can’t do the same because the bolt halves are glass hard. Annealing and rehardening in a furnace would cost more than the rifle.

There are things we can do to improve these rifles. Some stocks are walnut, but many are birch. The color of the birch runs from that of a canoe paddle to a sickly-looking orange/brown. A refinish using walnut-colored aniline dye (not stain) is a tremendous improvement.

Of the two items remaining, one is surprisingly not the tubular magazine. I cannot remember one ever being brought in for repair. Of course, my memory may be clouded by the mists of time as these rifles were most popular long ago in an era when giants walked the Earth and 500-round boxes of 22 bullets sold for just over $7 at the local big-box store.

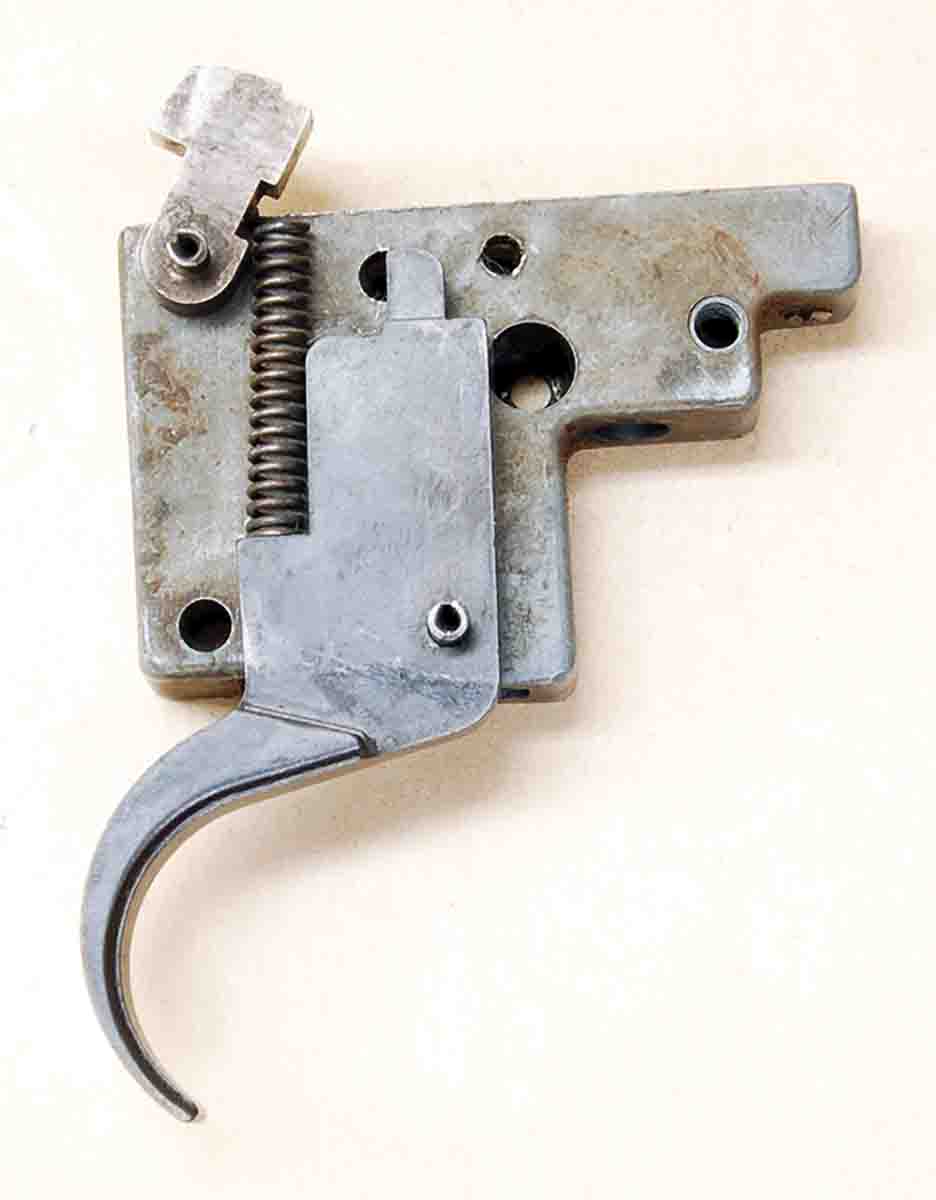

One strong spring is used for both trigger and sear return on non-target rifles. It must be replaced to obtain a decent trigger pull weight.

A problem we can fix is misfires. It seems the firing pin in the front half of the bolt is often obstructed by some type of fouling. This affects both the inexpensive models and target guns. It is, however, hard to see how this happens to some rifles and not others. I believe excessive oil is put in the bore when cleaning, then the gun is stored muzzle up. The oil runs down onto the bolt face and into the firing pin recess, eventually thickening with age.

The factory trigger-return spring (left) and its lighter replacement (right). Specifications are given in the column.

The slot that the firing pin moves in is only a couple of thousandths of an inch wider than the pin. It takes very little to inhibit its movement. Since the firing pin and its lot are exposed at the top of the bolt, it’s also possible that the owner thought it would be a good idea to oil them. Wrong! With the bolt body being glass hard, there is no need for any lubrication at all. The pin should display obvious looseness when the action is cocked. If it doesn’t, disassemble it as shown in the photo and clean out the slot.

Now, we come to riflefolks favorite topic – triggers. The one on the rifles we are discussing is a good one. Triggers on the target guns have some control over basic functions, while the ones on the Model 580, 581 and 582 do not. I will fix this.

Drilling a hole for the overtravel screw.

The first item is the sear engagement because it affects pull weight. The engagement notch is ground into the sear of these rifles and seems very uniform at .014 inch. This could be somewhat less, but separations when pulling the trigger (usually referred to as “creep”) could not be felt by those who shot the rifles. Being able to decrease sear engagement is not necessary.

Weight of pull is another matter as four standard models had release weights of 5.5 to 6.5 pounds. This makes the 5-pound rifles difficult to shoot accurately. This heavy pull is caused by only one spring being used to return (reset) both the sear and trigger after firing. A photo shows this clearly. The spring can be replaced to give a lighter pull without affecting reset capabilities.

The sear notch is a shallow .014 inch. There is no need for adjustment to non-target actions.

The new spring used here was arrived at by the cut-and-try method. It was cut from a longer spring in a Brownells light-duty spring kit. These assortments are also sold by hobby shops and Wolff Gunsprings. After a few tries, a spring .950 inch made from .018-inch diameter wire and having 16 coils per inch gave a pull weight of just under 3 pounds. Note that the new spring must be at least as long as the original because coil springs must be under moderate compression when at rest to function properly. Just cutting coils off the factory spring will not be satisfactory.

My last item is overtravel. Most folks try to ignore it on cheap rimfires, yet it is a major component of a good trigger pull. It is also simple to remove on these Remingtons. Drill and tap a 6x32 tpi (threads per inch) hole .450 inch up from the bottom front of the trigger housing as shown in the photo. Run a 6x32 tpi set screw into the hole and set the overtravel (use a .015-inch thick shim) through the inspection hole in the side of the trigger housing. Remember that the screw must be no more than flush with the outside of the housing to allow the safety/bolt-top mechanism room to function. Shorten, if necessary, then coat the threads with a thread-locker as the screw will never be touched again.

Setting the overtravel to .015 inch with a shim gauge and screwdriver after the adjustment screw has been installed.

The Model 580 single shot was discontinued in December 1978. It was a Stevens Favorite, Remington No. 4 and Winchester M67 all rolled into one, but also having lightning-fast lock time and a grooved receiver for scope mounting. It would last forever and with the trigger modified as done here, one could not ask for more. With the inclusion of the Model 581 and 582 (discontinued in December 1983) Remington had built the perfect inexpensive series of rifles, but apparently didn’t know it. If only they had used a decent clip magazine and kept the front half of the bolt from spinning around!