Keeping Rifle Barrels Cool During Load Development

Tricks to Stay Cool

feature By: Layne Simpson | September, 24

It is no secret that a skinny barrel heats up faster than a fat barrel. I recently shot a couple of HOWA Model 1500 Superlite rifles in 6.5 Creedmoor and 7mm-08 Remington. In order to keep the weight below 5 pounds, both have thin barrels measuring only .579 inch at the muzzle. Three rounds were fired and the barrels were quite hot to touch. Starting with a cold barrel, three-shot accuracy with one of the loads crowded half-minute-of-angle, but to maintain that level of accuracy, the barrel had to be completely cooled before shooting the next group. In contrast, is a switch-barrel rifle weighing just over 15 pounds with scope. The muzzle diameter of its heavy barrel in 6.5 Creedmoor is .910 inch and three rounds don’t heat it up enough to notice. In that rifle, I shoot five-shot groups and it will crowd quarter-MOA for three groups before asking to be cooled. While a fat barrel heats up slower than a skinny barrel, it is also slower at cooling down.

The gun club that I have been a member of for a very long time has more than 1,000 members and in addition to 30 covered benches, our rifle range has measured distances of 100, 200 and 300 yards. Many are experienced shooters and no small number have extremely accurate custom rifles chambered for various cartridges. In a serious effort to maximize barrel accuracy life while revealing true accuracy potential during load development, many shoot three to five rounds, followed by twiddling of the thumbs while the barrel cools down completely in preparation for shooting the next group. Some bring more than one rifle and while alternating between them seems to help, barrels will not cool down quickly enough to eliminate twiddle time completely. Wait time is long enough during winter and it grows longer with the arrival of summer heat. When developing an accurate load or trying several factory loads in a big-game rifle, allowing its barrel to cool completely between each group fired is extremely important. Doing otherwise can be meaningless, not to mention a waste of ammunition. Life is too short for sitting and waiting, so I drastically reduce the amount of time lost between groups shot by speeding up the barrel cool-down process. Doing so enables me to spend what would have been lost time on something productive.

Ways to skin the same cat are limited in number only by the imagination. Accuracy guru, Kenny Jarrett, has a handloading room and rifle range behind his shop and he or one of his assistants shoots every rifle to confirm a sub-half-MOA accuracy guarantee. Some rifles are ready to ship with minimal load development and very few groups are fired while others take a bit longer. The final groups fired are included with the rifle. To completely cool down barrels between groups, Jarrett rounded up automobile heater blowers from a junkyard and combined them with PVC pipe to push air through bores from the muzzle end. Their motors are DC, so an AC converter is used. The rig is capable of cooling three rifles at the same time and since three-shot groups are fired, the cooling does not take long. But it does take time away from other duties, so after firing a group in the three rifles, the shooter leaves them to attend to something else. His smart phone has an alarm set every 20 minutes to tell him when it is time to head out back and shoot another three groups.

A friend who is a farmer has a very nice rifle range behind his barn. Attached to the building is a small, well-insulated shooting house with both heat and air conditioning. In addition to a concrete shooting bench, it has a reloading bench and shelves with all the necessary tools for putting together ammunition. To shoot, he opens a small window and blasts away. An air compressor positioned about 20 yards away is used for barrel cooling. The nozzle of an air blow gun attached to its hose has a small plastic tube small enough to reach into the chamber of a barrel. Squeezing its trigger sends high-velocity air through the bore. My friend cautions that over time, condensation will form in the air collection tank of the compressor and it should be drained quite often.

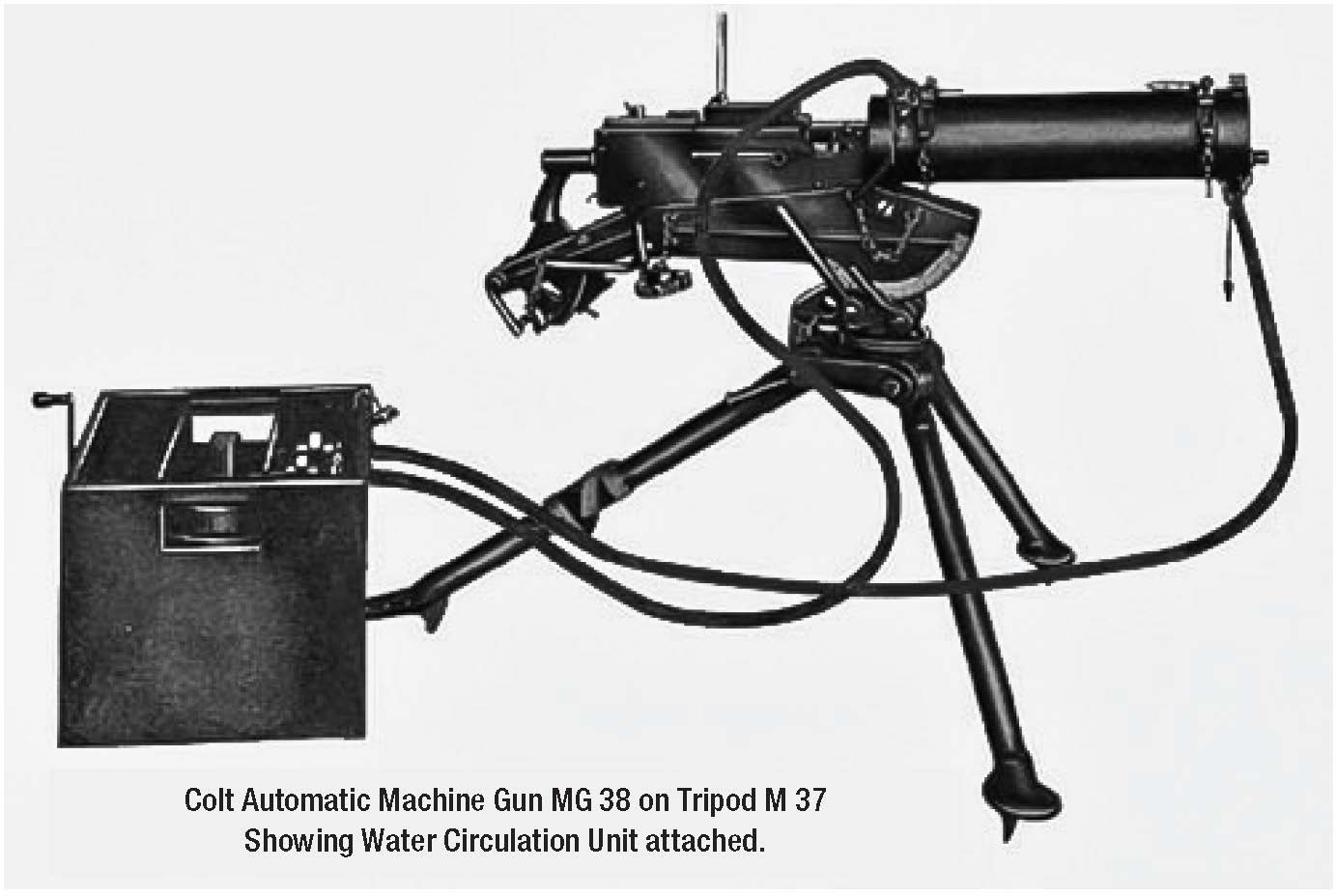

Water cools a barrel far more quickly than air and the idea is not exactly new. The barrels of early machine guns such as the British-designed Vickers and John Browning’s U.S Model 1917 were enclosed by a large metal jacket that was filled with water. During sustained firing, the water would begin to boil and then turn to steam, which exited through a small vent at the top of the jacket until all water was gone. In the absence of water during winter, a capped inlet on top of the water jacket of the Russian Maxim allowed snow to be packed in. The Colt Model 1924 may have been the most interesting. Designed to be fired from a fixed position, water could be circulated from a separate tank to the water jacket of the barrel and back again. One soldier aimed and fired, another was in charge of belt-feeding cartridges and a third hand-cranked the circulating pump of the tank.

When the shooting session ends, five rapid-fired rounds will evaporate any water remaining in the stock beneath the barrel but if it is not stainless steel, the stock should be removed and the barrel given an application of rust preventative. The ideal rifle for this type of cool-down is an AR-15 wearing a handguard with slots and openings that allow water poured through them to reach the entire surface of the barrel.

I prefer to run water through the bore because it is the quickest and most efficient way to cool a barrel uniformly over its entire length. It is also the way to water-cool a rifle with a wooden stock. Many trap fields throughout the country used to have water faucets with short hoses and dual-exit nozzles designed to allow water to flow simultaneously through both hot barrels of an over-under shotgun. It works equally well in other places too.

I have water-cooled hundreds of rifles through the years, many belonging to me, others consigned by various companies. My cool-down kit consists of a plastic bucket and four gallon-size plastic jugs, the latter for hauling water to the range. The show begins with pouring a gallon of water into the bucket. The homemade barrel cooler I have long used consists of a section of plastic tubing measuring .430 inch in diameter from the hardware store with a plastic funnel superglued to one end. With a rifle held muzzle down over the bucket, the end of the tube is pushed into the chamber until it stops. A plastic cup is used to pour water into the funnel slowly to avoid backflow. If one cup of water does not do the job, another is poured in. When the water in the bucket becomes warm to the touch it, is poured out and another gallon is poured in. After each cooling, the bore is wiped dry by pushing through three cotton patches prior to shooting the next group. How long does each cool-down take? I have been doing it for many years and can remove the bolt from a rifle, cool its barrel, push through three patches, install the bolt and be ready to shoot the next group in less than two minutes.

The number of shots fired between each cool-down during load development depends on the cartridge for which a rifle is chambered and the thickness of its barrel. For those that burn a teacup full of powder with each squeeze of the trigger (the 26 Nosler and 300 Ultra Magnum come to mind) in a light- to medium-heavy barrel, three shots is plenty. Moving to the opposite extreme, rifles in 17 Hornet, 22 Hornet and 218 Bee can be fired many more shots before the barrel becomes hot enough to increase group size. Whatever the cartridge might be, if a barrel is uncomfortable to the touch, it is ready for a cool down. Upon conclusion of a shooting session, the barrel is given its final cleaning with powder and copper solvents. A carbon-steel barrel is then given a light coat of rust inhibitor. In addition to being quick, easy and inexpensive, this cooling method will not harm a barrel heated to temperatures sporting rifles are commonly subjected to while developing a load.