J.P. Sauer & Sohn Sauer 100

A 6.5 Creedmoor Field Rifle

feature By: John Haviland | November, 19

I’ve been shooting 100 Cherokee 6.5 Creedmoor a couple times a week for several months. All that shooting enabled me to appreciate the German method of manufacturing an affordable rifle that is useful, usable and produces consistently good accuracy.

The Sauer 100 is made in seven models from basic to fancy. The Classic features a dark-stained beechwood stock, and the Classic XT, Ceratech, Cherokee and Atacama are all outfitted with polymer stocks that Sauer calls “ERGO MAX,” comprised of a slight forward slant to a straight comb, Schnabel fore-end tip, deeply fluted comb nose and tightly curved grip. The polymer stocks have an “air surface texturing” with a somewhat tacky feel that provides a sure grip.

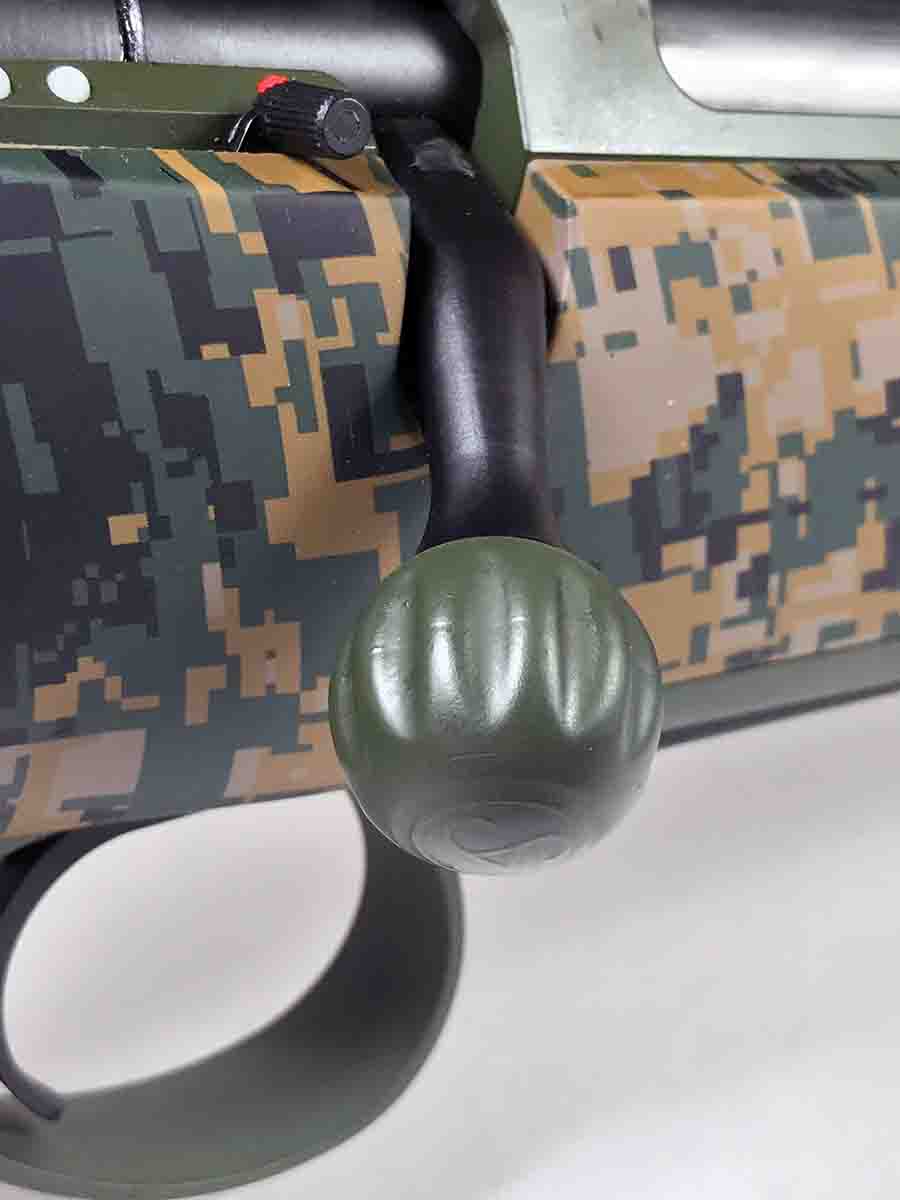

The Ceratech’s black stock is matched to a Grey-Ice CERAKOTE finish on the receiver and barrel. The Atacama’s stock is desert camouflage that blends into a Desert Sand CERAKOTE barreled actions while the Cherokee Woodland Digi camouflage merges into a Tundra Green CERAKOTE barreled action. Wild angles define the laminated-wood stocks on the Pantera and Fieldshot, which are adjustable for length of pull and comb height with vents cut in the forearm.

The Cherokee 6.5 Creedmoor I’ve been shooting weighs 7 pounds. The weight increased to 8 pounds, 11 ounces with the addition of a Burris Veracity 2-10x 42mm scope held in Talley Lightweight alloy scope mounts. A Magnum’s 2-inch longer barrel adds 3 ounces to a rifle.

The Sauer 100 has several features found on other budget-priced rifles that minimize machining. The action is basically a cylinder with a full-diameter bolt running through its center. This eliminates machining raceways in the receiver for the bolt to move along, and makes the receiver walls relatively thick and stiff. The bolt has little play during cycling as it is aligned by a tight fit slightly forward of the tang and inside the rear of the receiver bridge. It’s kept from turning and binding by the bolt stop pin extending into a long channel cut on the left side of the raised bolt. The ceramic CERAKOTE on the inside of the receiver further aids smooth travel.

With its three locking lugs, the bolt has a low 60-degree lift. The bottom–positioned lug pushes a cartridge out of the magazine as the bolt glides forward. A sliding blade extractor is recessed in the face of one lug. Two plunger ejectors on the opposite side of the bolt face positively throw cases and cartridges straight out of the ejection port.

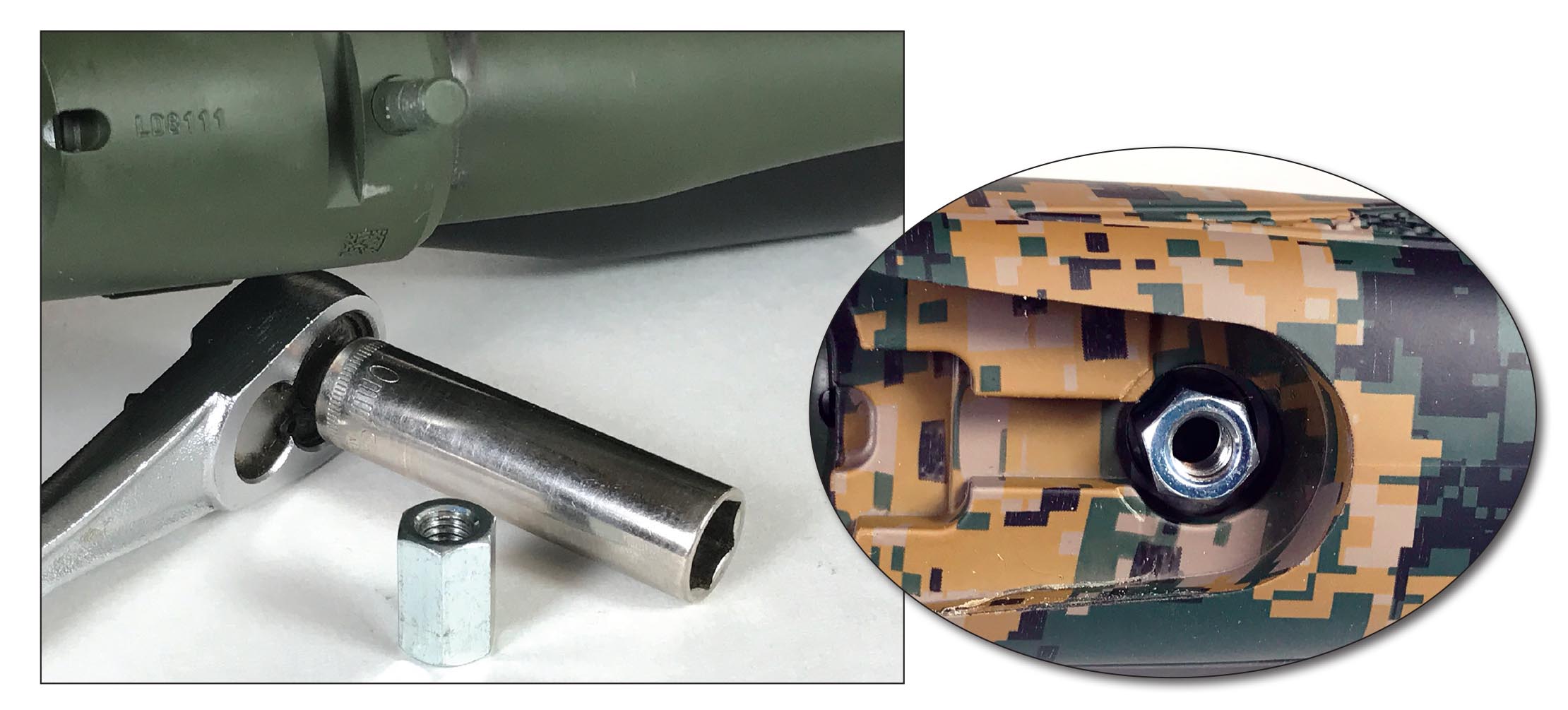

The Sauer uses a unique separate collar cut with locking lug seats that is inserted into the front of the receiver ring. This arrangement does away with machining lug seats in the receiver ring or the barrel. Plus, the steel collar encircles and shrouds the bolt nose when the bolt is closed. The front rim of the collar also works as an index point for the barrel when setting headspace.

Sauer barrels are cold hammer-forged. I peered into the bore of the Cherokee’s barrel with a bore scope. The leade was smooth and even around its circumference as it transitioned to the rifling. Not a single blemish marked the entire bore. Some streaks of copper-fouling adhered here and there on the rifling lands after firing 60-some cartridges.

The trigger is as good as any on a production rifle. Sauer says it’s adjustable from 2.2 to 4.4 pounds by turning a hex head screw on the top of the trigger shoe. The trigger on the Cherokee adjusted from 2.5 to nearly 8 pounds. It was set at 3 pounds as the rifle came from the factory box. Pull weight varied a few ounces. However, it had no creep or overtravel, and the stock grip placed my hand at the right distance and angle so my index finger fit perfectly on the trigger.

The 100’s receiver has a balanced look with its bolt shroud angled to blend flush with the tang and round receiver top merging into flats on the sides. A red-tipped pin extends from the bolt shroud to indicate the firing pin is cocked. The detachable magazine fits flush with an aluminum trigger guard/magazine frame inletted into the bottom of the stock. Pushing a recessed button in front of the magazine releases it.

Front and rear action screws attach the frame and stock to the receiver. However, with the screws removed the front of the receiver is still attached with a 10mm nut threaded onto a screw protruding from the bottom front of the receiver ring. The screw fits through an aluminum bedding block glued into the stock inletting. Sauer calls this assembly EVER REST action bedding. A crosspiece in the block fits into a slot in the bottom of the receiver to act as a recoil lug.

Further, the bedding block cradles the front of the receiver ring and a short portion of the bottom of the barrel. The rest of the barrel is free-floated with a sizeable gap between the barrel and stock’s barrel channel. An inch of stock material between the recoil lug and the magazine opening helps absorb recoil.

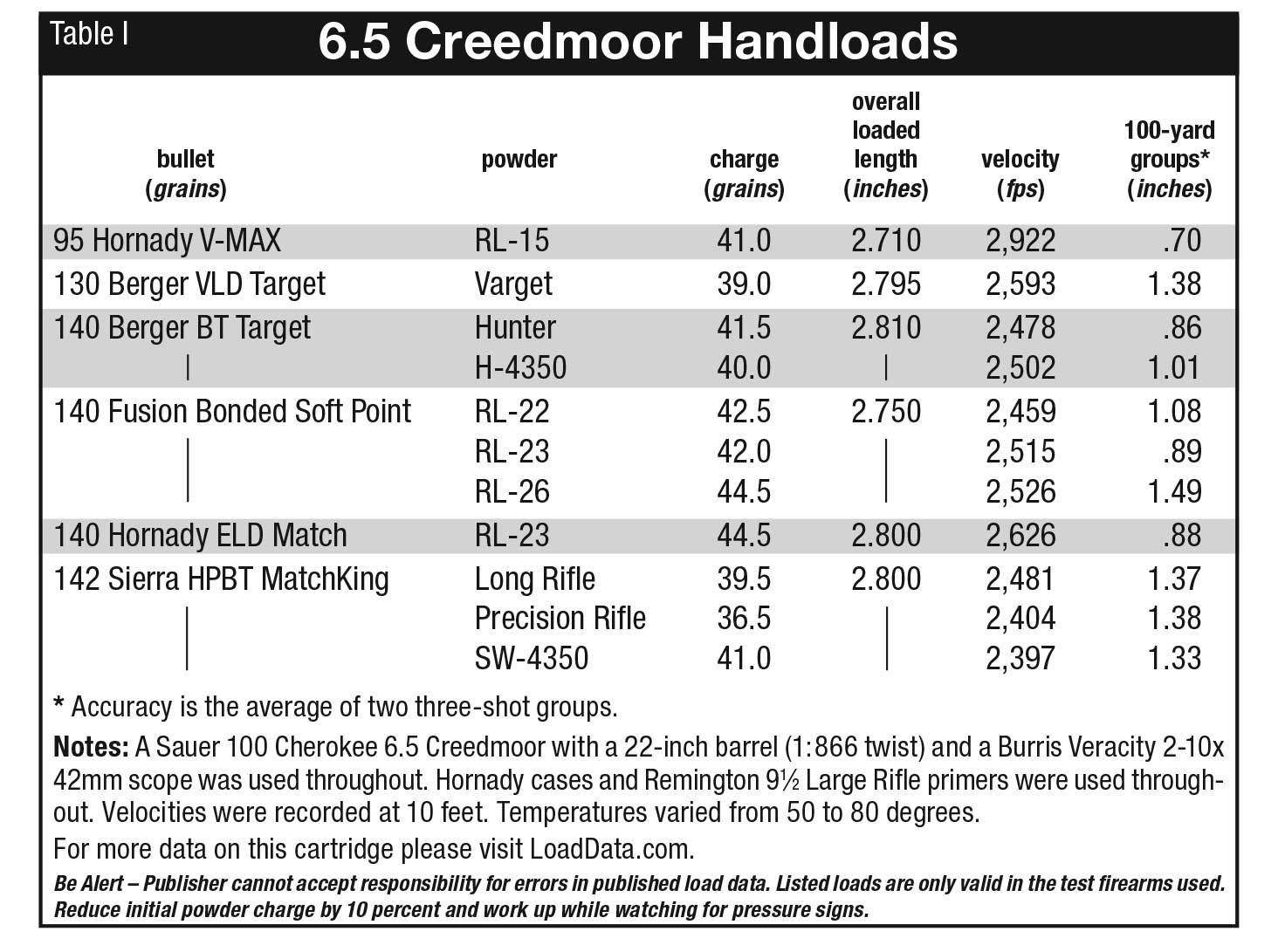

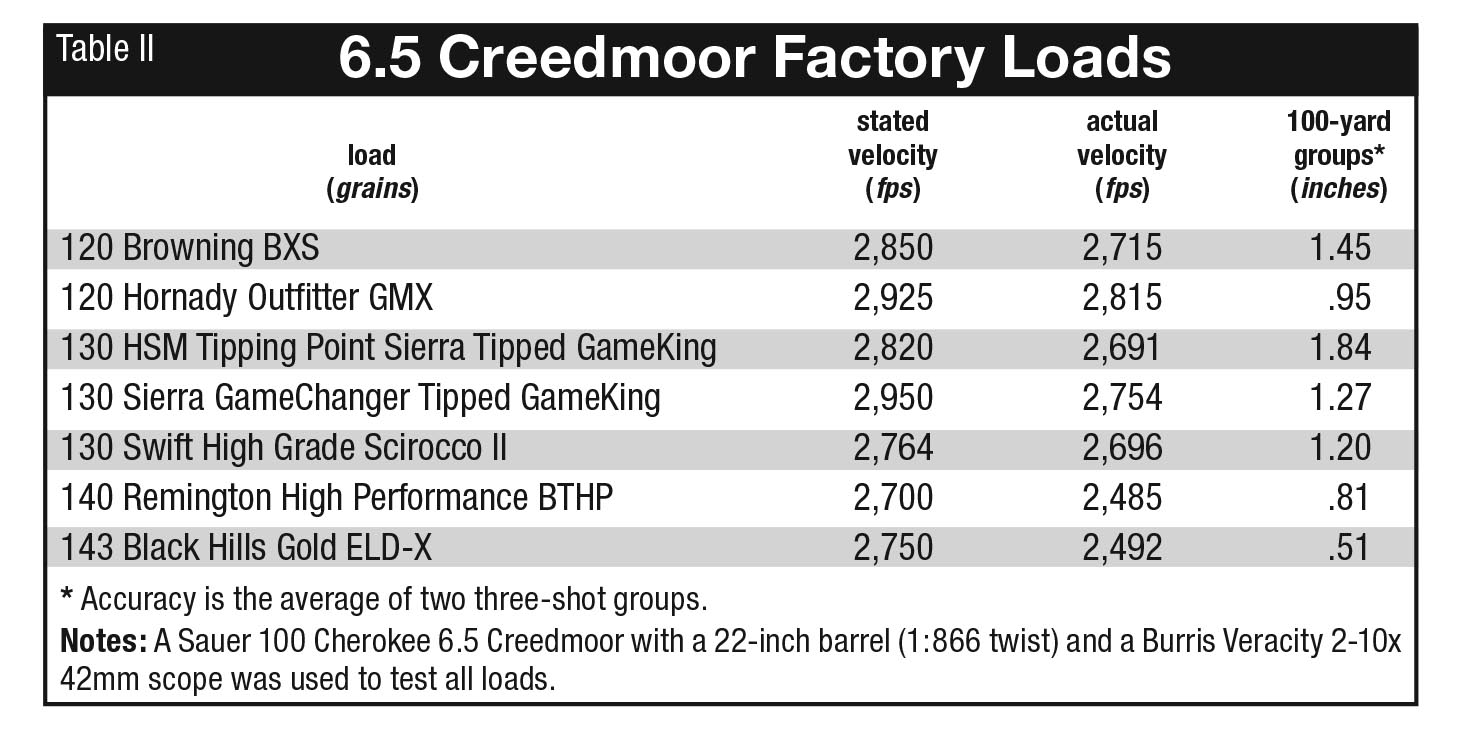

I started shooting the Cherokee with factory loads. Three of the seven loads exceeded Sauer’s guarantee of five shots in a minute of angle, although I used the average of two, three-shot groups instead of a five-shot group. To verify the Cherokee met its guarantee, I shot five Berger 140-grain BT Target bullets handloaded with Hunter powder. They printed a .79-inch group at 100 yards. Two, three-shot groups averaged .86 inch.

Velocity of some of the loads seemed slow compared to velocities listed on factory ammunition boxes. For instance, Sierra 130-grain Tipped GameKing bullets reached 2,754 fps from Sierra GameChanger cartridges that listed a velocity of 2,950 fps on the box. To check if my chronograph was on the blink, I positioned it and a second chronograph 10 feet in front of the Sauer’s 22-inch barrel on an 80-degree day and shot a few of the same loads. Velocities recorded by the chronographs were within 30 fps of each other. Velocities of the loads were also about 30 fps faster on the hot day compared to when they were fired on a 50-degree day. The same loads registered comparable velocities when fired from the 22-inch barrel of a Ruger American Predator.

Velocities of my handloads were also on the slow side of those listed in reloading manuals. The Berger Bullets Reloading Manual states a velocity of 2,700 fps for its 140-grain BT Target bullets loaded with 42.4 grains of Ramshot Hunter from a 24-inch barrel. The Berger bullets reached 2,478 fps loaded with 41.5 grains of Hunter from the Sauer’s 22-inch barrel.

One day I headed to the ground squirrel fields with the Sauer and a bunch of cartridges loaded with Hornady 95-grain V-MAX bullets and Reloder 15. Sitting with the rifle resting on a bipod, the little varmints within 200 yards were in peril. My position wasn’t steady enough to make sure hits much past that distance.

A black cloud sailed past and rain fell. The Sauer’s stock and CERAKOTE-protected metal shed the water like a duck’s back. The tacky surface on the stock and panels of stippling on the grip and forearm still provided a firm grasp.

The rifle was fluid to point when supported by my arms braced on my raised knees. That easy control resulted from my forward hand being wrapped around the slender forearm, the thick comb supporting my cheek and grip exactly positioning my finger on the trigger. I shot rocks at 300 yards and farther. When I missed, bullets hit low from misjudging the distance.

The rifle fed cartridges from the magazine so smoothly I opened the bolt a few times to make sure a cartridge was in the chamber. The Sauer did not bobble a single cartridge or fired case after shooting at least 350 rounds.

The German-made Sauer 100 Cherokee retails for about $900 while the basic Classic XT sells for $600. Those prices may not be bargain-basement, but they are still a good deal when the Sauer 100’s excellent stock and trigger, dependability and accuracy are considered.