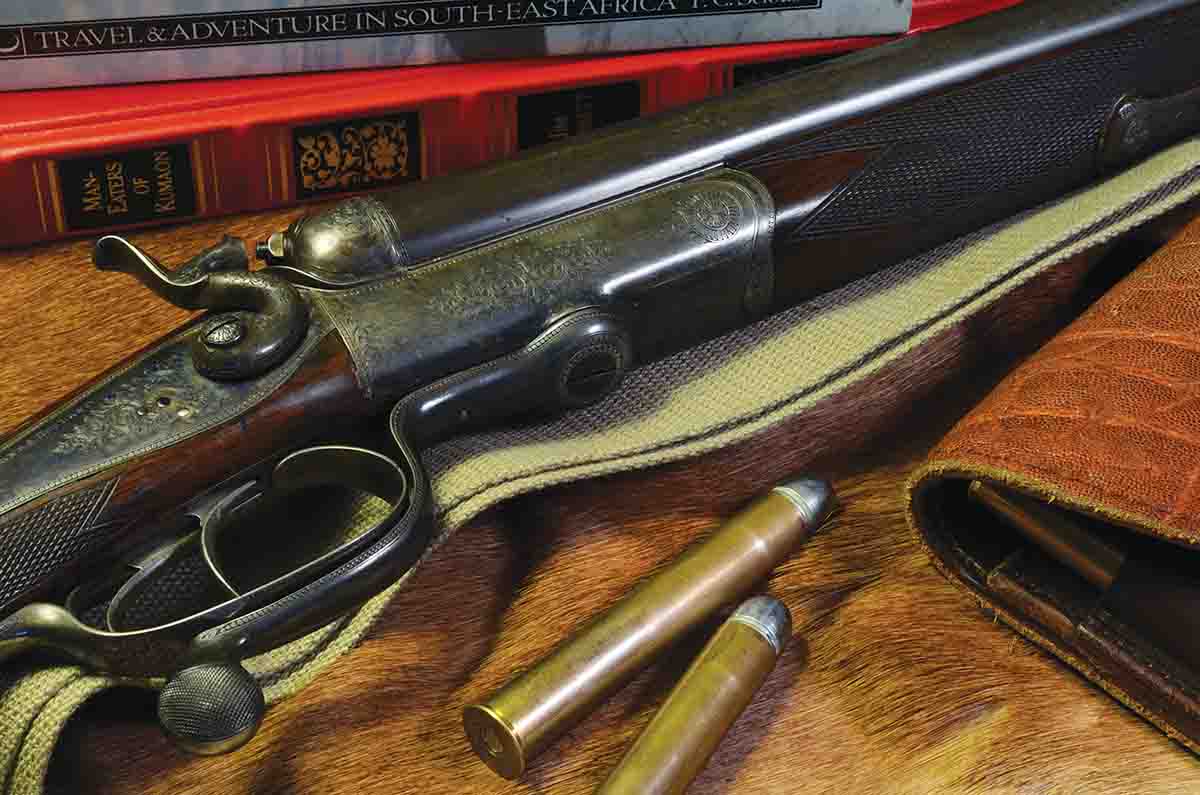

Double Gun Bolting Systems

Spindles, Bites and Underlugs

feature By: Terry Wieland | November, 19

Not to stretch out the suspense, the first is the sliding bolt that locks into the barrel’s underlugs, patented by James Purdey (1862); the second is the top lever and spindle down through the frame to operate this sliding bolt, patented by William Middleditch Scott two years later; the third is the Anson & Deeley boxlock action developed at Westley Richards.

Obviously, a sidelock rifle will not use the third feature, but the first two are so ubiquitous on side-by-side double guns and rifles of all descriptions, grades, makes and countries of origin that many shooters today don’t even believe they were ever new, revolutionary and subject to patent protection. “But that’s so obvious,” many riflemen will say. “Why would you do it any other way?”

Why, indeed? Well, like fire, the wheel and the whale-stay corset, truly brilliant ideas are characterized by the fact that to the generations that follow they look painfully obvious. What is not widely known is that, after Casimir Lefaucheux awakened English gunmakers to the possibilities of the break-action mechanism in 1851, it took more than a decade of intense activity to develop systems of bolting them closed that were workable and durable – never mind convenient and ergonomic – and another 15 years before the systems we now recognize as “obvious” came into general use.

The Lefaucheux hinges the barrels on a pin at the front of the action. They drop down to open the breech, and up to close it. Once closed, the barrels need to be locked in place using a method strong enough to withstand the stresses of firing, yet have a release mechanism that makes it easy to open, extract empty cases, reload and close. These stresses are essentially the same for both shotguns and rifles, although in the latter they are considerably greater.

In the beginning, barrels had one underlug that mated with the hinge pin. This could be used as a locking lug as well, and with the low pressures of the early pinfires it worked well enough. Unfortunately, being situated several inches from the breech, it turned the barrels into levers, magnifying their downward movement on firing, tending to force the action open. This leverage was eliminated by adding a second lug closer to the standing breech, purely for locking purposes.

The second lug may have grown out of a design by Henry Jones, the Birmingham gunmaker who invented the Jones underlever, one of the best, and certainly the strongest, locking mechanisms of all time. This lever wrapped around the trigger guard and was swung out to the side to unlock the action. Internally, Jones lengthened the single lug, then milled a T-shaped slot into which the T projection of the lever locked. By giving the arms of the T a slant like a screw thread, the lever cammed the barrels down tightly as the lever swung closed.

Jones’s milled slot effectively turned one long lug into two shorter ones, and from there it was a short step to having double underlugs, with each contributing to bolting. In Purdey’s patent (No. 1104) of 1863, there are two underlugs, each with a slot or “bite.” A plate, shaped like a squared figure “8”, slides back and forth in the action bar. Its edges fit into the bites in the lugs, holding the barrels down. As the plate is pushed forward, it releases the lugs and allows the barrels to pivot downward; as the barrels are closed, the forward curved edge of one lug cams the plate back out of the way; once the barrels are in place, the spring pushes the plate closed, engaging the bites and locking the barrels in place. This system is generally referred to as “Purdey double underlugs” in catalogs describing rifles and shotguns, whether from Spain, Austria, Belgium or any other country.

If the Jones lever had one major drawback it was the fact that it was fully manual, or “inert.” That is, it had to be pushed out by hand, then pulled back into position the same way. A great virtue of the Purdey double underlug with its spring-powered plate was that it was readily adapted to “snap” actions – mechanisms that locked themselves automatically as the barrels were swung closed.

This was the budding age of driven shooting, with an ever-increasing emphasis on rate of fire. This was not so important with double rifles, and innovations in shotguns tended to be applied to rifles only later when they had been fully tested and proven, but eventually it all caught up and today the mechanisms for shotguns and rifles are essentially the same.

William Middleditch Scott was a brilliant Birmingham gunmaker, the “son” of W. & C. Scott & Son, one of the foremost Birmingham makers. The company supplied many of the guns and rifles that went to London and later bore the names of companies like William Evans and, up until 1893 or thereabouts, Holland & Holland. The quality of Scott products was unquestioned. William Middleditch Scott (his middle name is always used to differentiate from his father) was the inventive driving force of the company in the later 1800s.

Having studied the Purdey bolt, he contrived a spindle that went down through the rear of the frame from the top strap, between the hammers. This was operated by a lever that lay along the top strap and could be operated by the thumb without removing the hand from the grip. A cam on the bottom of the spindle simply pushed the bolt forward against the spring pressure. The lever had its own internal spring to push it closed, so all that was needed to close the action and lock it in place was to simply lift the barrels.

Scott patented his spindle in 1865, and together Scott and Purdey proceeded to get rich. They treated their patents as a pair; Purdey collected a royalty every time a London gunmaker used them, while W. & C. Scott did the same for Birmingham and the regions, including Scotland. The Purdey patent expired in 1877, by which time Purdey was the preeminent London maker, and James Purdey himself a wealthy man.

As Donald Dallas described it in The British Sporting Gun and Rifle (2008), the Purdey bolt and underlugs are “simple, convenient, hard wearing, and very strong.” Ironically, its strength was not fully appreciated at first and many gunmakers, including Purdey, looked for a “third bite” to supplement it. This was partly due to the influence of J.H. Walsh (“Stonehenge”), editor of The Field, who was a great believer in maximum strength – understandable, since one hand had been severely damaged in a gun accident early in life, ending his career as a physician.

Many different approaches to a “third bite” were tried but the most common was an extension of the barrel rib that locked into the standing breech. Some were simple “doll’s head” extensions – knobs that fit into a corresponding opening in the standing breech. Others were flat blades that fit into a slot. In theory, a doll’s head helped alleviate the tendency of the barrels to push forward, while a simple blade only prevented lateral movement.

In Birmingham, W.W. Greener used a blade but added a sliding bolt that passed through it from side to side. This was operated by the top lever. The “Greener crossbolt” became a fixture, mainly on lower priced guns in England (aside from Greener’s own) and on the continent, particularly Germany. For reasons no one has ever explained, several Greener inventions became standard in the German trade, including his sliding safety on the left side of the frame.

Purdey’s own “third bite” was a smaller rib extension that fit into the standing breech but was not visible when the action was closed. Being small and unobtrusive, it did not get in the way of fast loading.

John Rigby & Co. contributed in the form of a locking mechanism, patented by Rigby and gunmaker Thomas Bissell in 1879, called the “rising bite.” This became legendary in its own right. A rib extension in the form of a steel stirrup rib fits over an elongated post in the standing breech, and a post rises to fill the end of the U. This is immensely strong – far stronger than required for any shotgun and is extraordinarily difficult to make.

The irony is, however, that none of it was really necessary. The basic Purdey design of double underlugs, sliding bolt and Scott spindle could handle any cartridge up to, most recently, the .700 H&H; in 2009, Holland & Holland made a four-bore double rifle – 24 pounds of pure power – and if memory serves, it had no third fastener. H&H was never a fan of them anyway. Of course, my memory may have been addled from shooting it.

Another irony: The Jones underlever, which logically should have been rendered obsolete by the more elegant and convenient Purdey sliding bolt, continued in production right into the 1920s. It was favored for rifles like the huge .577 and .600 Nitro Express, and for economy working rifles destined for India and the colonies, where gunsmiths were few and far between and a broken spring could be fatal. The Jones was refined over the years, with gunmakers coming up first with a “partial snap” design where the lever closed halfway by a camming action as the barrels were raised, allowing the shooter to push it home with his fingertips while gripping the rifle, and later by a “full snap” design. Still, it could never be as convenient, fast and elegant as the Purdey-underlug/Scott-spindle combination.

When the Anson & Deeley boxlock action was patented in 1875 it made full use of both the Purdey underlugs and Scott spindle and went on, I am given to understand, to be the most widely produced industrial mechanism in history – manufactured to this day, around the world, in virtually its original form. Steels have improved, machinery has become more precise and various ways have been found to reduce costs, but the A&D soldiers on – a combination of three English patents from the nineteenth century that set the standard for the world.