Browning BAR Mark 3

A new .30-06 repeates and old tradition.

feature By: Stan Trzoniec | January, 17

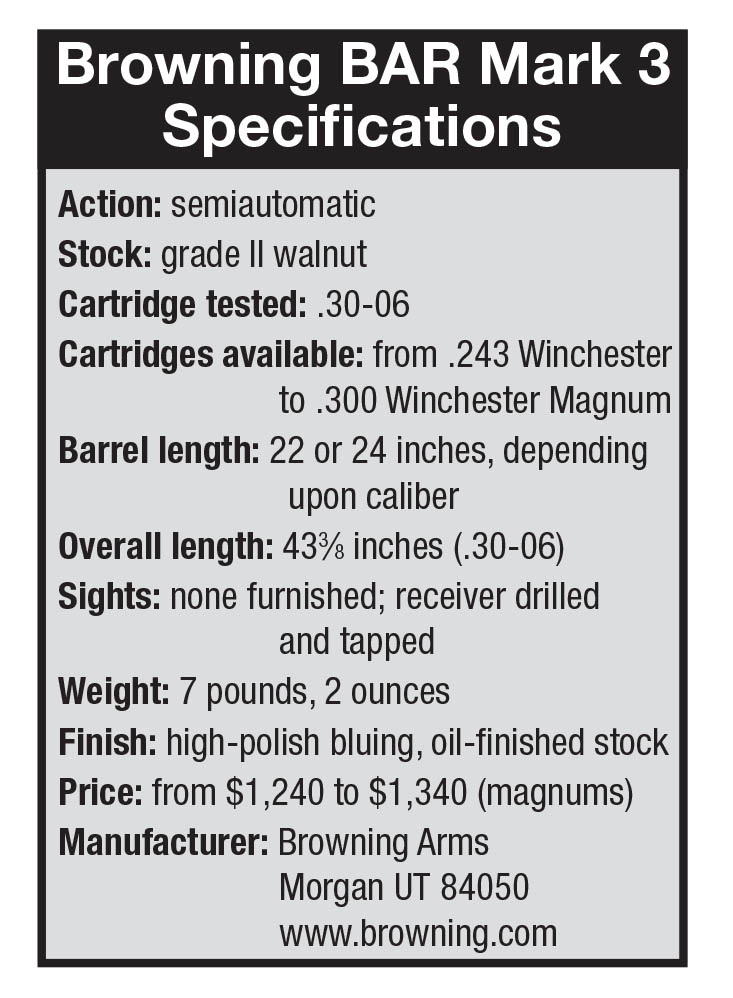

Browning introduced its first semiautomatic sporting rifle in 1967. It was only available with a 22-inch barrel in four standard calibers to include the .243, .270 and .308 Winchesters and the .30-06, as reviewed here. The following year, the 7mm Remington Magnum and the .300 and .338 Winchester Magnums started to fill out the line, with the .338 Winchester deleted in 1975. In 1967, only two versions – Grade I and Grade II – were available; some four years later, 10 versions were offered with the Grade V Magnum at $880.00 topping the list.

Bruce Browning, son of Val Browning, spearheaded the design of the BAR sporting arm. It was initially produced in Belgium with assembly transferred to Portugal – as it still is today. Over the course of the production life of the rifle, many variations emerged with the emphasis on flawless operation and quality.

While the Mark 3 follows the same general outline of the previous Shorttrac and Longtrac BARs, there have been some updates.

On all accounts, the Mark 3 is a good-looking rifle. According to Browning’s literature, all the wood is Grade II. This puts it into the “no knots or disturbing grain patterns” type of wood. The test sample’s stock is of a coffee/orange color mix with a straight-grain pattern moving up toward the receiver. The forearm matches the buttstock in color and grain, something I like to see, because then I know both were cut from the same blank. There is ample checkering on both the forearm and the buttstock, with the former almost circling the wood and the latter featuring a pleasing pattern complimenting the lines of the stock. The diamonds are cut at 24 lpi (by my count) with no overruns and a double line around each pattern for a custom look. The stock is oil finished and smooth to the touch.

For those looking for a comfortable stock to hold and shoot, this Browning BAR may be the answer. When first picking up the rifle, I had to think twice if the stock was made for me! The forend, almost 14 inches long, is just the right dimension with enough of a taper to the rear to place the hand at just the right spot for shooting. Moving to the buttstock, the pistol grip has a swell for right-handed shooters and a 13

Popular today is the classic school of stockmaking. There is no line-disturbing comb or cheekpiece. Flutes cut near the wrist of the stock are for comfort, and the only thing I would add would be a pistol-grip cap to protect the pistol grip itself. (I have seen many rifles with chipped pistol grips.) A proprietary Inflex recoil pad is standard and is rounded in all the right places for easy mounting.

Metalwork on the rifle is naturally above par. The bluing on the barrel is deep and rich. Contrast is added by the satin-nickel finish of the receiver, which is complete with detailed floral pattern etchings on each side circling the Browning logo. The receiver is machined from an aircraft-grade alloy while the “bottom metal,” including the trigger guard and floorplate, are a black composite. Releasing the floorplate via a lever forward of the trigger guard allows the magazine to drop open while still attached to the rifle. You can load the open magazine (four or five rounds, depending upon the cartridge) or release it in one deft motion. Extra magazines are available from Browning.

No sights are furnished by Browning, but the receiver is drilled and tapped for common BAR bases and rings. In my box of tricks, a Burris one-piece base and pair of high-gloss Browning medium rings were found. To these a Leupold 3.5-10x 40mm scope was installed. The rich color of both the rings and scope enhanced the look of the rifle.

The BAR’s gas-operating system reduces the recoil sensation, even with the largest cartridges. For riflemen who would like to

The BAR’s rotating bolt has seven lugs that lock into the barrel. The rigid action bar and inertia block are made to provide years of service while an internal buffering system reduces stress and wear on the rifle’s mechanism. Over the years, I found that routine maintenance is beneficial to a BAR, especially after range testing, and it assures reliable operation on the next hunt. In the field, where you might be lucky to get off a half-dozen shots, there is no need for any concern with this rifle.

The jeweled bolt stays back after the last shot. To the right of the ejection port is a red dot. Some hunters prefer to leave the bolt locked open and then release it when the stalk begins. Naturally, you are not going to let the bolt slam forward by using the bolt release that allows it to close with a loud

For an autoloading rifle, the trigger is rather pleasant to use. There is a bit of take-up – much like a two-stage trigger – but after that, the gold-plated trigger broke at 41⁄2 pounds with no overtravel. The safety is right behind the trigger, a cross bolt in design with a hearty detent, indicating when it has been moved from “safe” to “fire.”

To disassemble the rifle for cleaning, first pull back on the bolt handle to settle the action to the rear. To get at the gas mechanism, use a No. 11 metric wrench to remove the sling swivel stud. A No. 4 metric Allen wrench is then needed to back out the front screw. Carefully pull the forearm forward and down to expose this part of the rifle. When cleaning this part of the rifle, be careful not to allow the bolt to slam forward without the forearm attached. If you ever have to clean the trigger group, removing the twin trigger group pins allows the mechanism to be removed without any problems.

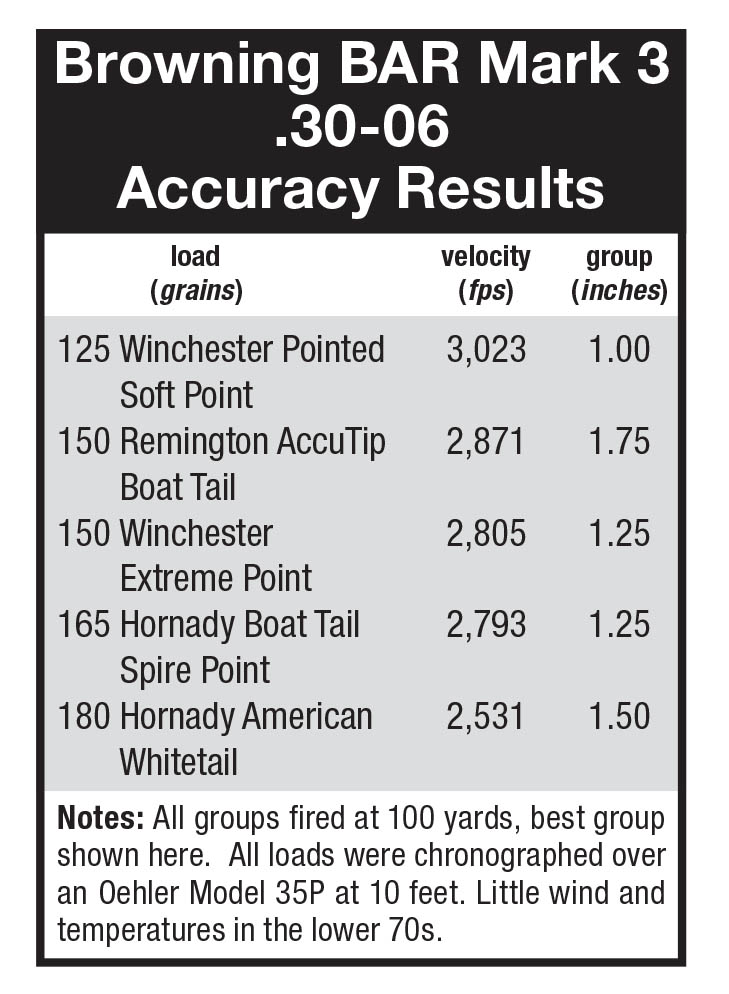

For groups, I always allow the barrel to cool a few minutes between shots and five minutes between groups. Working this way gives the barrel a chance to maintain a constant temperature, which to me is a precursor to good groups. The best group was with Winchester’s 125-grain Pointed Soft Point loads with three shots measuring an inch. Remington’s 150-grain AccuTip Boat Tails fared fairly well with the best group just sneaking under the 2-inch marker. At almost 2,900 fps, I find this bullet weight in the .30-06 perfect for a wide range of game animals. Its counterpart, Winchester 150-grain Extreme Points

Empty cases were thrown a good distance from the test rifle. When working with this BAR, I tried single loading as well as from a full magazine with no difference in group size. The recoil was a push instead of a hard jolt; in fact, I could feel the delay as the gas operation came into play. The BAR 3 is priced right, has high standards in fit and finish and is accurate.