Winchester Model 1873

Testing a New Version of an Old Classic

feature By: Mike Venturino Photos by Yvone Venturino | November, 17

According to the company’s own advertisements, Winchester’s Model 1873 was the “Gun that Won the West.” (It did not, but that’s another story.) It was produced for almost a half-century to the tune of almost three-quarters of a million rifles. According to The Winchester Book by the late George Madis, actual manufacture of Model 1873s stopped in 1919 at serial number 720,610 with the last ones assembled and sold in 1924. Interestingly, Madis indicated that only 18 were sold that first year of production.

In truth, ’73 Winchesters did spread westward rather quickly. Modern archaeology research at the Little Bighorn Battlefield has proven that no fewer than eight were fired in that historic 1876 fight between Sioux and Cheyenne warriors and the U.S. Army’s 7th Cavalry Regiment. All the 1873s were in Indian hands, as no documentation exists that any soldier or army scout had one.

There were two firsts connected to the Model 1873. It was Winchester’s first rifle to use ferrous (iron) metal for the receiver, which was replaced by steel in the 1880s. More importantly, it was Winchester’s first rifle chambered for a centerfire, reloadable cartridge. It was the .44 WCF, today commonly called .44-40, the second set of digits standing for the amount of black powder factory loaded under 200-grain, lead-alloy bullets. Worthy of note is that the ’73 rifle was also introducted with a set of reloading tools, including bullet mould, wad punch and powder dipper. Cost for the set was $5.

Throughout its production, Winchester offered Model 1873s in three standard configurations: rifle, saddle ring carbine and military musket. In the same order, their barrel lengths were 24, 20 and 30 inches, all round in shape. Also from the beginning, octagonal barrels were available for rifles as an extra cost option. In an 1899 catalog reprinted by Wolfe Publishing years ago, an octagonal barrel cost $1.50 extra.

The .44 WCF was the initial and sole chambering until 1879. At that time, Winchester cartridge designers simply necked the case down to take a .400-inch, lead-alloy bullet and called it the .38 WCF. Why it was named .38 when it was actually .40 caliber has been a mystery ever since. Of course, it is now called .38-40. In 1882, a newly formed cartridge was introduced, the .32 WCF, known today as the .32-20. The brass cartridge lifters of ’73s were inscribed with the caliber after 1879. Winchester began offering Model 1873s chambered for .22 Short or .22 Long (not Long Rifle) in 1886. Those rifles are instantly recognizable by the lack of a loading port on the receiver’s right side.

When discussing any Model 1873, old or new, it is necessary to discuss strength. After John M. Browning joined the firm, Winchester leverguns had locking lugs that rose to secure bolts; however, bolts in ’73s lock by means of toggle links that break over center to hold them shut. In its 1899 catalog, Winchester subtly referred to the matter. In discussing ammunition, the Model 1892 was referenced with smokeless-powder factory loads, but the description of Model 1873s only covered black-powder factory loads.

In 2013 at a firearms industry gathering, someone placed a new Model 1873 in my hands. I was surprised. It was labeled “Winchester” but was a product of Miroku in Japan, the same company that has built the Models 1886, 1892, 1894 and 1895 reproductions bearing the Winchester name. These are imported by Browning Arms Company, which licenses the famous name. Time only allowed me to fire 10 rounds through the 20-inch, round-barreled short rifle.

Those 10 fed and fired perfectly, and all bullets hit the target. Regardless, I was disappointed because the sample was chambered for .357 Magnum. I also learned .45 Colt would be the next option. Being immersed in my writing Shooting World War II Small Arms at that time, I handed back that Winchester ’73 .357 Magnum and promptly forgot about it.

In the first few months of 2017, I purchased three vintage ’73s, all from the late 1800s. That’s when I begin to think about new ones again. Research showed that the new Winchester ’73s had come a long way in four years. The fact that the .44-40 is now a caliber option was most interesting, along with the fact that there are pistol- grip stocks, color casehardened receivers, full 24-inch barrel lengths and octagonal barrels available. I asked Browning for a loaner .44-40 in whatever shape or size was available soonest.

It happened to be a short rifle, meaning it had a round, 20-inch barrel. Its stock is typical with a crescent steel buttplate and straight grip. The wood is oil-finished American walnut, plain grained and well fitting but not custom-rifle perfect. Length of pull is 12.75 inches. There is a steel forearm cap securing the forearm to the barrel. This Winchester 1877 Short Rifle has a full-length magazine tube holding 10 rounds.

The metal was nicely blued and polished. Of course, the cartridge lifter was made of brass, as were the originals, and the caliber is even inscribed as it should be, except instead of simply “44 cal,” new rifles are marked “Cal .44-40 Win.” Sights consist of a buckhorn rear with slider for elevation. At front is a tall blade with a brass bead. Both sights are dovetailed to the barrel and can be drifted to obtain a windage zero. I quickly noticed that this rifle’s tang was also drilled and tapped for mounting a peep sight.

Put this following comment in the “trivia” column if you want, but even after owning perhaps 50 Winchester leverguns and writing a book about leverguns, Shooting Lever Guns of the Old West, available from Wolfe Publishing, I learned something after seeing those screw holes in this new ’73. My Winchester Models 1876, 1886, 1892 and 1894 have one extra screw hole for mounting a tang peep sight. For a second screw to secure it, remove the stock screw and mount the sight with a slightly extra-long screw usually supplied with the sight. I initially thought this new Model 1873 deviated from standard Winchester practice. It does not. An examination of four original Winchester Model 1873 rifles shows two tang screw holes for peep sights. (My single original saddle ring carbine has no holes for mounting a tang sight.) This is a small but interesting point.

A factor that has to please legions of shooters buying new Winchester leverguns is that these ’73s do not have the dreaded exterior tang safety or rebounding hammer found on some Miroku/Browning leverguns. There is indeed a safety. It is an inertia-type firing pin arrangement in the bolt. The hammer goes down when the rifle is fired and stays there, and a peep sight can be mounted on the tang.

That brings us to shooting the new Winchester Model 1873 .44-40. In a nutshell, I found it a far easier rifle with which to hit a steel target than to shoot groups on paper. The problem was with me, not the rifle, so I’ll explain: The brass bead front sight is close enough to my eyes that it quickly goes out of focus. Groups of two or three shots reasonably clustered into 2 to 4 inches at 100 yards. Then, as my eyes got tired, there would be flyers – almost always significantly high or low.

As any good rifleman would do, I initially blamed the rifle. I’ve shot a great many open-sighted rifles and have loaded tens of thousands of .44-40s, so this Winchester was not a new experience. No matter what I tried, however, the up and down flyers persisted, turning 2- to 4-inch three-shot groups into 6- to 8-inch five-shot groups. Then the proverbial lightbulb came on. My eyesight just was not good enough to hold elevation with that brass bead and buckhorn sight. (By the way, that bead subtends 8 inches at 100 yards.)

About 20 years ago, Lyman re-introduced its No. 2 tang peep sight, and there were several on hand. One, intended for Model 1886s, fit perfectly on the new ’73, and suddenly the vertical flyer problem was solved. The human eye automatically centers a front sight in a rear aperture, even if the former is a bit fuzzy in one’s vision. Most groups rounded out nicely.

The important word in the above paragraph is “most.” Some groups were plain terrible, and here is where modern manufacturing and antique cartridges cross swords. Going back to original Winchesters for a bit, the earliest one I’ve ever owned was made in the early 1880s. It was in fine condition with a good bore considering its age. Even with black-powder handloads, it initially sprayed bullets. Those bullets, incidentally, were from RCBS mould 44-200-FN, my all-time favorite .44-40 bullet. Cast from 1:20 (tin-to-lead) alloy, these roundnose/flatpoints weighed 214 grains and were sized .428 inch. From a Uberti/Cimarron Model 1873 .44-40 and a 1905 vintage Winchester ’73 musket, that bullet shoots fine with black or smokeless powders.

The problem was with that early Winchester’s barrel groove diameter. I slugged it three times. It came out .433 inch each time. My 1:20 alloy bullets were not slugging up enough to fill the rifling grooves. That ’73 was made to shoot to at least a mediocre level by casting bullets of pure lead.

Winchester evidently got its barrel manufacturing problems under control, because I’ve now slugged several ’73s made in the 1890s and early 1900s that uniformly were .427 inch across their grooves, and they shoot nicely with .428-inch, lead-alloy bullets.

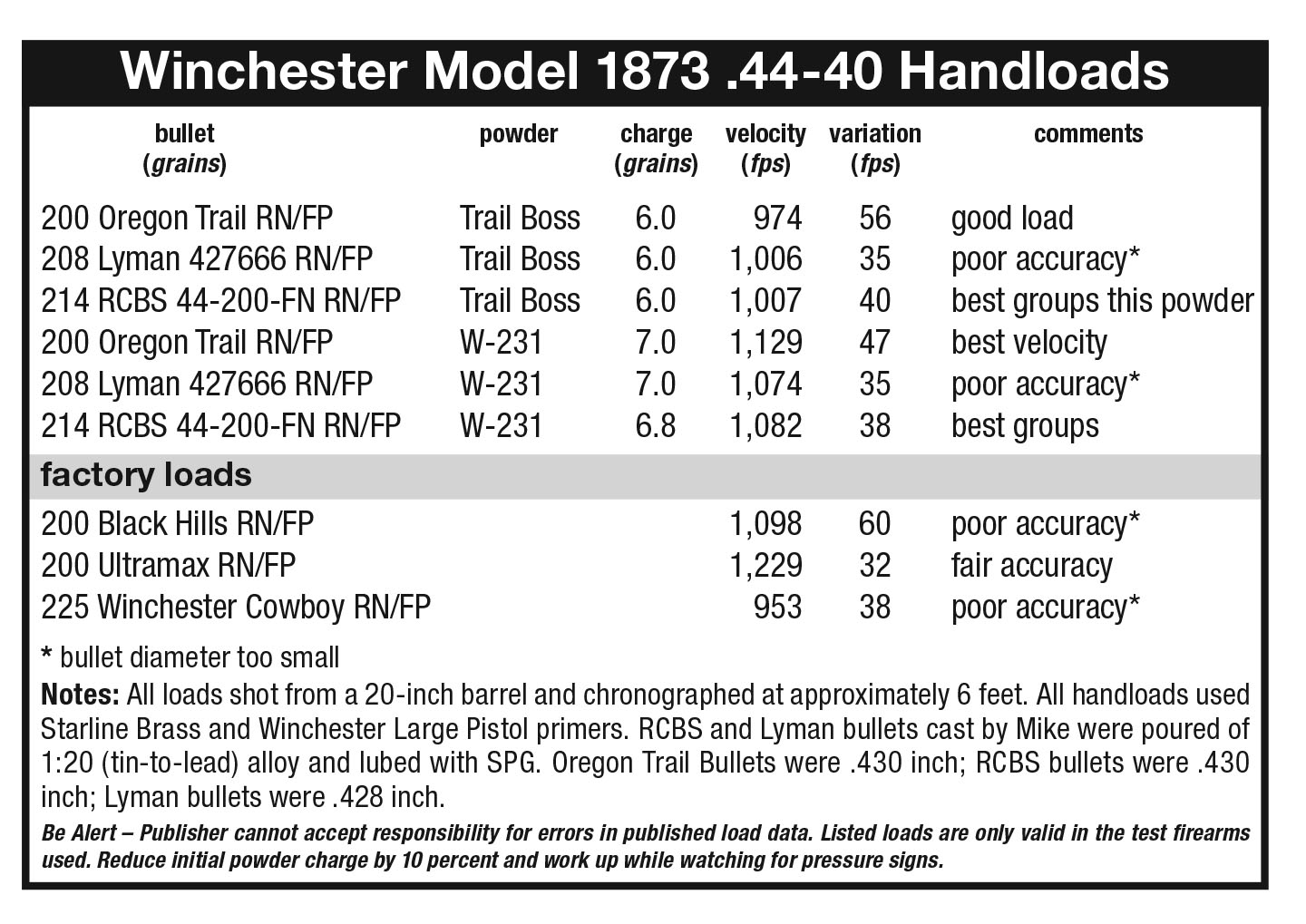

The loads that the new Model 1873 did not shoot well all had .427-inch, lead-alloy bullets and all were rather mild loads – either factory types or my handloads. I suspected the problem, and slugging verified it. Miroku made this barrel’s groove diameter the same as it previously made .44 Magnum barrels, .429 inch. When fired with .430-inch, lead-alloy bullets, either my own or examples from commercial casters, the best accuracy was realized.

Groups did not get tiny, nor should they, for this is a nineteenth-century rifle and cartridge design. This firearm is obviously meant for cowboy action competition, small-game hunting or simply plinking. Honestly, except for chronographing and group shooting with the listed loads, most of the 500 or so rounds fired through this ’73 sample were shot while plinking at steel for fun.