Shooting the Echols Legend .375 H&H

New Proprietary Action

feature By: John Barsness | January, 22

As I cruised the show the first morning a sturdy, medium-sized blond man behind a small table full of rifles said, “You’re the guy who wrote that book!” He recognized me from photos in the optics book, and I recognized his name on the banner behind his table. We talked for a little while, but hunters kept stopping by to check out his rifles, and I wanted to see the rest of the show, so we agreed to meet later.

We spent most of the next few days in his booth, because I had looked at all the other booths that first day, and the first question to D’Arcy from attendees was, “How much do your rifles weigh?” Sheep hunters hike steep country a lot, and while D’Arcy has built some pretty light rifles, most of his customers spend more time hunting bigger game, preferring rifles that hit harder and weigh more than “mountain rifles.” D’Arcy (who at the time also guided elk hunters in the Utah mountains) eventually remarked that he never knew there were so many 300-pound sheep hunters who wanted rifles weighing a pound or two less than his.

Most soon started bypassing D’Arcy’s booth, so we got to talk a lot. He showed me some of the nifty features of his rifles, especially the Legend model, based on Classic Model 70 Winchester controlled-round feed actions that he essentially rebuilt, with McMillan synthetic stocks D’Arcy designed for the purpose. Unfortunately, only so much can be demonstrated in a small booth with a few rifles, and he invited me to visit his shop some time, where he could demonstrate the details that went into each Legend.

The Twin Towers fell during my flight, and on arrival at the Salt Lake airport all the TV monitors were turned off – but even at seven in the morning, the concourse’s bars were standing room only, because they left their TVs on. Every passenger was informed their luggage would take days to unload, and would be shipped to them, and we needed to get home however we could.

I called Eileen, who was extremely worried because New York City was the next leg of my trip, and she immediately started driving down to pick me up. In the meantime, I phoned D’Arcy, who said a shuttle bus ran every day from the Salt Lake airport to Logan. We could spend the rest of the day in his shop, which would also cut nearly 100 miles off Eileen’s drive.

At first D’Arcy and I talked about the morning’s events, but eventually we were glad to move the conversation on to hunting rifles. It turned out he did far more than the typical “blueprinting” of factory actions to ensure the barrel gets screwed on straight and centered. He also replaced the factory extractor with a more advanced model from Winchester’s custom shop, and also fitted custom-made magazine boxes and cartridge followers, then touched up the feed rails and ramp until cartridges with any type of bullet fed and extracted perfectly.

He also worked over the Model 70’s famous three-position safety. Many Winchester fans move the safety lever to its middle position when anticipating an imminent shot at game, which allows the lever to be pushed forward with less movement and noise. Unfortunately, this can allow the bolt handle to lift slightly, and when that happens in some (not all) Model 70s, the safety lever refuses to go forward. This occasional fault had played a part in some incidents on dangerous game, one a severe pounding of a safari client – though luckily not fatal – by a Cape buffalo.

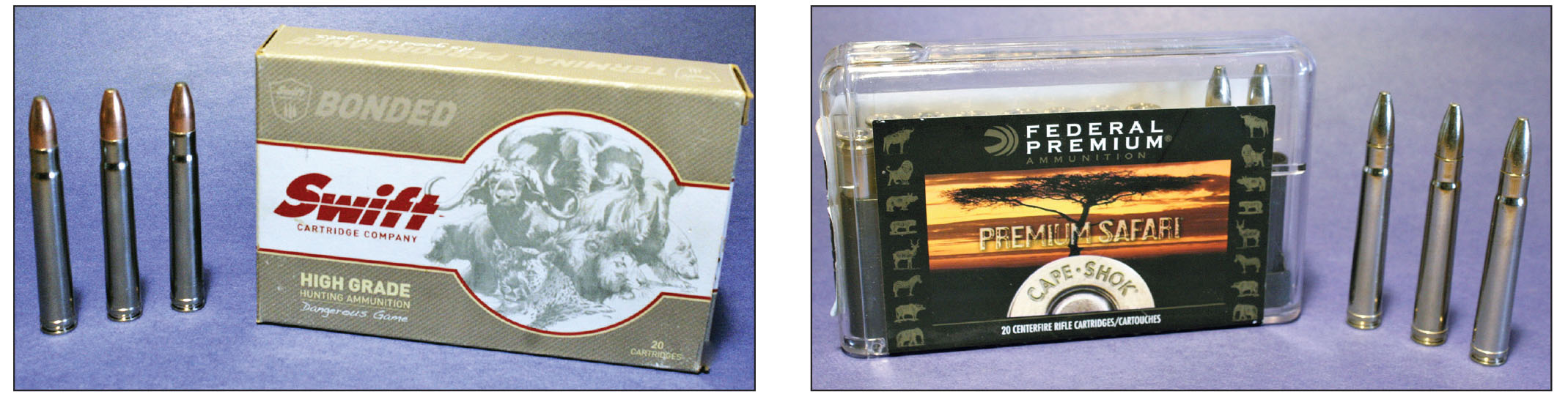

This kind of detail-oriented work does not come cheap, but on that day the list of scheduled orders on the shop wall included several Legend rifles. Somewhat surprisingly, all but one were for common cartridges such as the .30-06, .300 Winchester Magnum and .375 H&H. D’Arcy said his typical customer was a world traveler, who instead of desiring some trendy new round – the choice of many rifle loonies ordering custom rifles – wanted to be able to find factory ammunition anywhere it might be available. (There were a couple of other rifles on the list, his “Classic” model with walnut stocks. Echols is also a very fine traditional stockmaker, partly because he was the very first apprentice of legendary custom riflesmith Jerry Fisher – back when Echols was still in gunsmithing school.)

We met several more times over the years at winter conventions such as the Shooting, Hunting and Outdoor Trade Show (SHOT), or Safari Club International, where hunters meet to look at gear, book hunts, socialize and even tell the occasional lie. We also phoned each other when something inspired us, such as one of Echol’s customers demanding a Legend in .458 Lott that would group both softnose and solid bullets into .5 inch. D’Arcy opened the call not with a hello but a question: “Just how small are elephants these days?”

Eventually, he decided to design his own action, partly because he grew weary of working over Model 70 Classics – or even finding them. That could happen during “shortages,” like the one occurring right now, when many firearms companies cannot keep up with demand.

He called the action the LX-1, a play on the name of his daughter and frequent hunting partner Lexie, and had it produced by a local Utah company, partly so he could personally take part in any problem-solving. (Northern Utah is a hotbed of manufacturing for the space industry.)

Early in 2021, he told me the first LX-1 rifles would be put together that spring and asked if I wanted to test one. I said sure, but the first few rifles he sold immediately went on hunting trips. The test rifle finally appeared in September – a .375 H&H that had already taken a Cape buffalo.

It turned out to be a .375 H&H heavier than I tend to prefer, weighing 10 pounds, 5 ounces with an 18-ounce Swarovski Z8i 2-8x 24mm scope. Now, I have managed to pack hunting rifles weighing 10-plus pounds over quite a bit of hunting country, including what passed for mountains in the Selous Game Reserve of Tanzania – but my .375s have weighed 8.5 to 9 pounds. However, the customer said he wanted it over 10 pounds, and “if you make it any lighter, I’m bringing it back!”

The action was designed to have basically the same “footprint” as the Model 70 Classic long action, so the same McMillan stocks could be used. The stock on this rifle was what McMillan calls a “sniper pour,” heavier than Echols’ standard stock, which weighed 2.2 pounds with a Galazan recoil pad. This is considerably heavier than many other synthetic stocks, and even somewhat more than the average walnut sporter stock.

The 24-inch Krieger barrel also measured over 0.7 inch at the muzzle, which made the rifle balance a little weirdly, so D’Arcy tapered the front half of the barrel, forward of the forend, down to .64 at the muzzle, which still resulted in the specified 10-plus pound weight.

In fact, with 5 rounds of 300- grain ammunition and a typical 4-ounce sling, the rifle weighed exactly 11 pounds on my scale. This made it more comfortable to bench test than a lighter .375 H&H, and as expected, shot very well, though as usual, exactly how well depended on the ammunition. The two factory loads tried went into about 1.5 inches for three shots at 100 yards, but D’Arcy’s favorite .375 handloads featuring the Swift 300-grain A-Frame shot far better. (So did my favorite reduced .375 H&H hunting load with the Hornady 220-grain flatnose, which pretty much duplicates “modern” .38-55 velocities. I worked it up close to 20 years ago for practicing with an aperture-sighted Ruger No. 1 before going on a scope-free Botswana safari, to duplicate the same point of impact as full-power, 300-grain hunting loads. It shot very close to the same point of aim as D’Arcy’s 300-grain A-Frame handload. Unfortunately, the 220-grain Hornady is among the bullets dropped from production during the present shortage, though like others have in the past, it may reappear after the panic buying stops.)

Building accurate custom rifles, however, is pretty easy, especially with so many fine custom barrels available these days. Echols uses both Krieger and Bartlein cut-rifled barrels, whichever he can get (because there is an unprecedented demand for barrels right now). Instead, he’s perhaps even more obsessed with other aspects of rifle function, as I learned in 2001.

One of the most notable features of simply firing the LX-1 Legend was how easily rounds ran from the magazine into the chamber – and ejected, whether the cartridge had been fired or not. This is partly due to using magazine boxes and followers designed to precisely work with different cartridges, and also often custom-fitting the extractor to the brand of case. As Echols pointed out, the extractor-groove diameter of different brands of brass can vary, and one of the “secrets” of controlled-round feeding in a typical claw-extractor action is putting the correct amount of extractor tension on the groove. If it’s too tight, the cartridge cannot rotate in the bolt face, so it resists flowing from the magazine to the chamber. If too loose, the extractor can “drop” the round. If the customer plans to use a single brand or brass or factory ammunition, Echols can adjust the claw for a perfect fit.

He also designed a different, very rugged bolt-stop with a toggle lever. He pointed out that many of today’s bolt-stops depend on the strength of the relatively small pin holding it in the action, which might not survive when a strong but excited hunter jerks the bolt back hard during a Cape buffalo charge. The Echols stop consists of a steel wedge with a flat face, and the rear of the wedge fits firmly against the square hole inside the receiver.

The wedge also helps slow and divert any hot powder gas that might escape along the left bolt raceway due to a blown primer or case. One of the weaknesses of the Model 70 action, ever since the original model appeared in the 1930s, has been its gas-handling. Essentially, there is none, with hot gas blowing directly back into the shooter’s face. (As some gun writer once suggested, “modern brass cases made the pre-’64 Model 70 possible.”) While most shooters will never experience a blown case in a Model 70, I have – and felt very grateful to be wearing glasses.

The 98 Mauser action, on the other hand, is well-known for its gas-handling, largely due to a flange on the front end of the bolt-sleeve, which diverts gas sideways. The LX-1’s bolt-sleeve has a Mauser-type flange.

The trigger is essentially the highly-regarded pre-1964 Model 70’s, an “open” design that tends to shrug off water, dust and even ice. This particular trigger, however, is made more precisely than triggers in older Model 70s, both pre- and post-1964. (Winchester switched to an enclosed trigger several years ago, with the moving parts sandwiched between two pieces of sheet metal.)

The trigger, and almost all of of the rest of the LX-1 action, is made by Central Valley Machine in Logan. The exceptions are the firing pin, made by Greg Tannel of GreTan rifles, while the firing pin springs (there are two) come from famous target shooter David Tubb. His Duo springs are wound in opposite directions, and placed together, end to end, around the firing pin. They eliminate the typical bolt-handle “jump” that occurs when most bolt actions are fired, due to the “twist” a single firing-pin spring imparts when it unwinds. (I tested this with the Echols rifle, and the bolt handle remained dead stable when the firing pin dropped.)

The top of the receiver ring and bridge are angle-edged flats milled to fit the LX-1 scope bases, with a notch in each flat matching a tab in the bottom of the rings, a very strong system. Because both the action and mounts are precisely made by Central Valley, the scope ends up centered on the action, without having to adapt an individual set of rings to the action.

As production of the LX-1 action increases, Echols will start selling them to other folks for making custom rifles. In the meantime, he will continue to build hunting rifles as safe and reliable as he can make them.

.jpg)