Product Tests

Hammer Bullets

whatsnew By: Staff | March, 19

Hammer Bullets are available in all popular calibers from the .17-caliber 18-grain Dead Blow Hammer to the .42-caliber 420- grain Hammer Hunter. Dead Blow Hammer bullets are made with a deep hollowpoint that results in a relatively low weight retention of 50 percent. Hammer Hunter bullets have a boat-tail and long nose taper. A shallower hollowpoint helps retain about 70 percent of their original weight. Heavy Hammer bullets are designed with a flat base and wide ogive and are heavy for their length, but with a fairly pointed nose. Heavy Sledge Hammer bullets feature a fairly wide tip. “The Sledge Hammer is for hunters who shoot game at normal ranges,” Davis said. Lever Hammer bullets have a wide, flat point to enable loading them in a tubular magazine. Target Hammers have a solid tip.

Davis said Hammer bullets tend to develop lower pressure due to less bearing surface contact with the bore. “Seating depth adjustment for accuracy has been unnecessary, making for much less time spent creating an effective load,” he said.

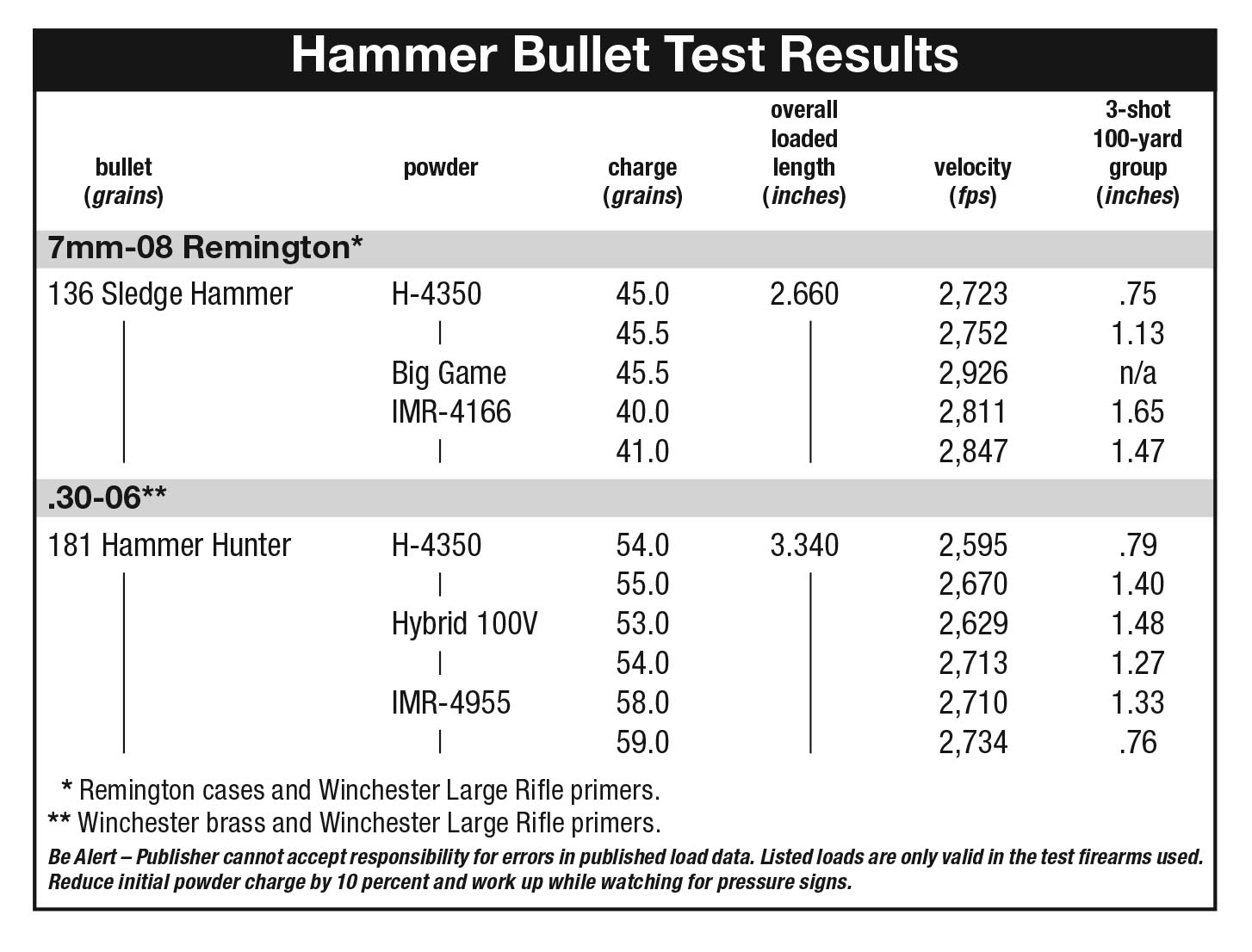

Sledge Hammer bullets have a short ogive that required seating them deeply in 7mm-08 cases so the bullets did not contact the rifling. That required an overall cartridge length of 2.660 inches and set the bullet’s shank deep into cases. The bullets were loaded with powder charges about three grains below maximum listed for conventional lead-core bullets. Those powder charges were close to maximum for velocity. Accuracy was good, with groups of .75 inch to 1.65 inches.

Hunter .30-caliber, 181-grain bullets have an extended boat-tail and long,

Both bullets, with impact velocities of about 2,600 fps, drilled 11.5 inches into dry bundles of newspaper. The Sledge Hammer bullet sheds its nose, and several pieces of it were found an inch or so short of the bullet. The nose of the Hunter bullet had slightly expanded, and the bullet came to rest bent like a banana. Davis said that was normal, as the bullet requires some fluid forced into its hollowpoint to initiate expansion. He said it readily expands in game at impact velocities down to 1,800 fps. For more information, visit hammerbullets.com. – John Haviland

MEC Marksman Reloading Press

Mayville Engineering Company (MEC), Inc., of Mayville, Wisconsin, continues to expand its product line. Now presenting itself as MEC Shooting Sports, since 1955 the company has been recognized as the world’s premier maker of shotshell reloading presses. An all-encompassing lineup includes basic single-stage presses through to pseudo-progressive hydraulic and electric models and an impressive array of accessories. In 2013, MEC began offering a line of clay target-throwing machines, and in 2015 a line of one-piece, 12-gauge plastic wads.

More recently MEC introduced a metallic cartridge reloading press with a broad list of accessories to include a powder measure, vibratory tumbler, case lube and a bullet puller, to name a few. A sample of the Marksman press was used for this review, and it has been used quite a bit.

The MEC Marksman is a single-stage press holding one reloading die at a time. The frame is cast iron and all other parts are steel; it is a very stout press. Its construction is listed as “C-channel” style and may well be the most ambidextrous-friendly press on the market. The entire front of the press is open for 180 degrees, and the operating handle can be set for left- or right-hand operation.

Press clearance from the top of the shellholder to the press top is about 4¼ inches, providing sufficient clearance to accept larger cartridges. In MEC literature it is noted, “Reload .22 Hornet to .416 Rigby with one convenient machine.” All handgun cartridges can be accommodated as well.

MEC has an interesting approach to securing the shellholder. A spring-like steel wire is depressed and the shellholder slides into place. The shellholder is then allowed to free float, insuring proper centering of the case when it enters the die. Press operation is straight forward; lowering the handle raises the ram and case. The press does not cam-over; rather the ram stops at its top-most position. The press comes with complete instructions, parts list and a mounting template.

There are several things I like about this press in addition to its heavy construction and user-friendly operation. The press is attached to the mounting surface by three bolts; one centered behind the ram and two at the rear of the base. It seems to me this is a more secure mounting system than most I’ve seen.

The maximum bench thickness for press mounting, allowing for the primer catching mechanism to function, is about 2 inches. The clearance under the benchtop, from front to back, must be at least 4½ inches. The press is available with an optional base accessory that allows the press to be mounted well above the benchtop – about 8 inches. The base, in turn, is compatible with the MEC mounting jig fixture that allows for the quick interchange of presses.

My first impression was that mounting the press on the base would be ideal for those who prefer to reload while standing. For those of us who prefer to sit, mounting the press on a bench would be more practical. To my surprise, operating the press using the base while sitting turned out to be quite comfortable, so don’t dismiss the system out of hand.

The base comes with extensions for holding dies, and it accepts several trays for more tools and other components. The tool- holding tray that attaches to the back of the press functions well, as did trays with a small connecting arm.

There is no on-press priming capability. According to MEC, most reloaders use a bench-mounted or handheld priming system, and therefore the option was unnecessary. I admit when loading a large number of cases I typically use either a bench-mounted priming tool or a handheld tool. There are times, though, when loading a very few cases at a time, I appreciate being able to prime on the press.

When depriming, the spent primers fall through the hollow ram into a catch tray mounted under the press. This works – almost all of the time. On rare occasions a primer would lodge in the trough at the bottom of the ram, which directs the primers into the tray. On even rarer occasions a primer would fall out of the ram onto the benchtop or floor, depending on whether I was using the base. This is not a major problem, but it can be annoying, and the Marksman press is certainly not the only press thus hampered.

I noted a couple of other things as well. Lee Precision makes a ram-prime accessory that screws into the press and allows for on-press priming. It requires handling each primer individually, but so do many other on-press priming systems. In the end, it is a quick-and-easy solution. For handloaders who use the Lee Bench Plate system for easy remove-and-replace mounting of handloading tools, the Marksman press can also be attached to the Lee baseplate, but it will require drilling additional holes. This would be applicable when the MEC base accessory is not in use.

In the end, we have another press. If you are in the market for an exceptionally strong, ambidextrous, single-stage press, take a look at the MEC Marksman. For more information, visit MecShootingSports.com or call 800-7797-4632. – R.H. VanDenburg, Jr.