Custom Corner

Sitek Arms

column By: Stan Trzoniec | January, 18

Considering that the original wood was all but destroyed, starting from scratch was the only alternative. Checking his stock of premium wood, John Sitek

The stock is finished with oil and rubbed by hand. The checkering is a skip-line, ribbon pattern checkered at 24 lines per inch (lpi). There is an Asiatic buffalo horn Schnabel forend cap with a widow’s peak. For field carry – if the owner takes this rifle in the field – there is a two-screw sling swivel stud on the buttstock while a barrel band holds the front stud forward of the forend tip. To complete the stock, a curved metal buttplate was installed and checkered by hand at a conservative 29 lpi.

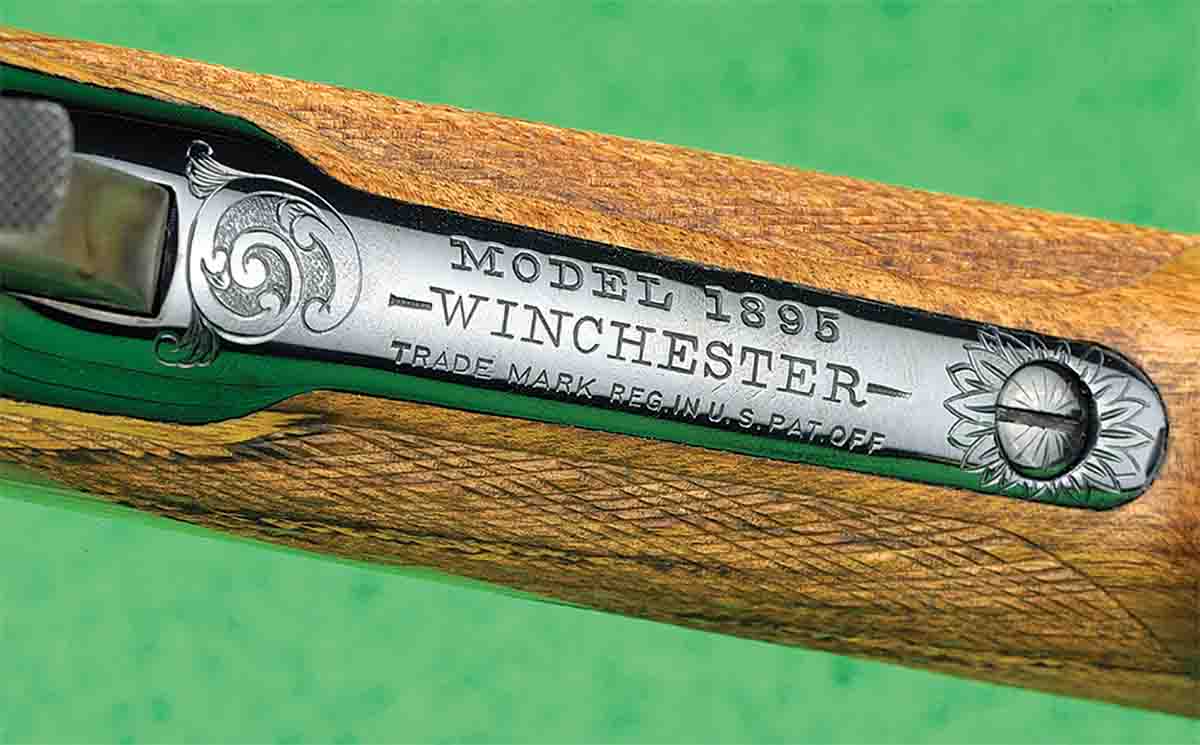

While the stock was a challenge, the metalwork on the rifle took many hours of hard work. To maintain all of the original markings, master metal smith Ted Sitek removed all the heavy pitting by draw filing and “papering” to ensure all of the lines, markings and the final details were preserved. In addition, all action components were hand-honed for smoothness, and the trigger, hammer and stock screws were color case hardened. The original Winchester three-leaf rear sight was refurbished, a barrel band and hooded front sight was added with Alex Sitek finishing up the polishing and matte contrasting. Master engraver Rachel Wells of Prescott, Arizona, did all the engraving in a standard scroll pattern, keeping with the age and period of the rifle. For more information, contact Sitek Arms at www.sitekarms.com or 800-485-9508.