Bergara Custom Rifles

feature By: John Haviland | November, 18

In 2006, Spanish company Bergara created a good name for itself in the shooting world by producing accurate barrels that placed one bullet after another in the exact same spot.

Bergara followed up in 2012 with a line of custom rifles made in the U.S., featuring its barrels on actions made by other manufacturers. In 2015 Bergara started producing its Premier series and then the B-14 series of production rifles. These rifles have been well received by shooters and hunters and have taken up the majority of Bergara’s sales.

Bergara uses its Premier action on its custom rifles, although it will build rifles with about any

brand of bolt action. The custom rifle line includes the Sport Hunter, Varmint Hunter, Long Range Hunter, Competition, Heavy Tactical and Heavy Tactical Chassis. These rifles are chambered in 13 cartridges from the .22-250 Remington and 6mm Creedmoor to the .300 and .338 Winchester Magnums.

“The air is pretty thin up there for rifles that cost several thousand dollars,” Treadaway said. “But there are still guys who want to buy unique and special rifles.” For employees in its custom shop in Lawrenceville, Georgia, Bergara recruits former military personnel who worked in the U.S. Marine’s Precision Weapons Section. Their duties, among others, were to build and maintain the Marine’s bolt-action M40A5 sniper rifle. “So they are experts at making accurate rifles,” Treadaway said.

Barrels installed on custom rifles are the same Bergara barrels used on Premier rifles. However, the custom shop’s two full-time employees take accuracy several stages farther with barrels for custom rifles. They inspect barrel bores with a scope for

flaws, lap the bores, cut chambers by hand and watchfully crown barrels. The barrel breach is trued, matched to an action, and the barreled action is inletted into a McMillian stock – or a customer’s stock choice.

From there the sky is the limit for options. The Premier action is the most popular, although customers can select any action they want. Barrels can be fluted, and contours vary from lightweight and standard sporter to lightweight and standard varmint. Most standard cartridges are made with a 22-inch barrel, and magnums are made with a 24-inch barrel. Customers can choose a Timney or Jewell trigger, a blind magazine or a magazine with a hinged floorplate, or a detachable magazine.

Building a rifle from start to finish takes about 40 hours, Treadaway said. The Premier action is the heart of Bergara custom rifles. “The action is made in Georgia,” he said, “and soon we hope to have it made in-house.”

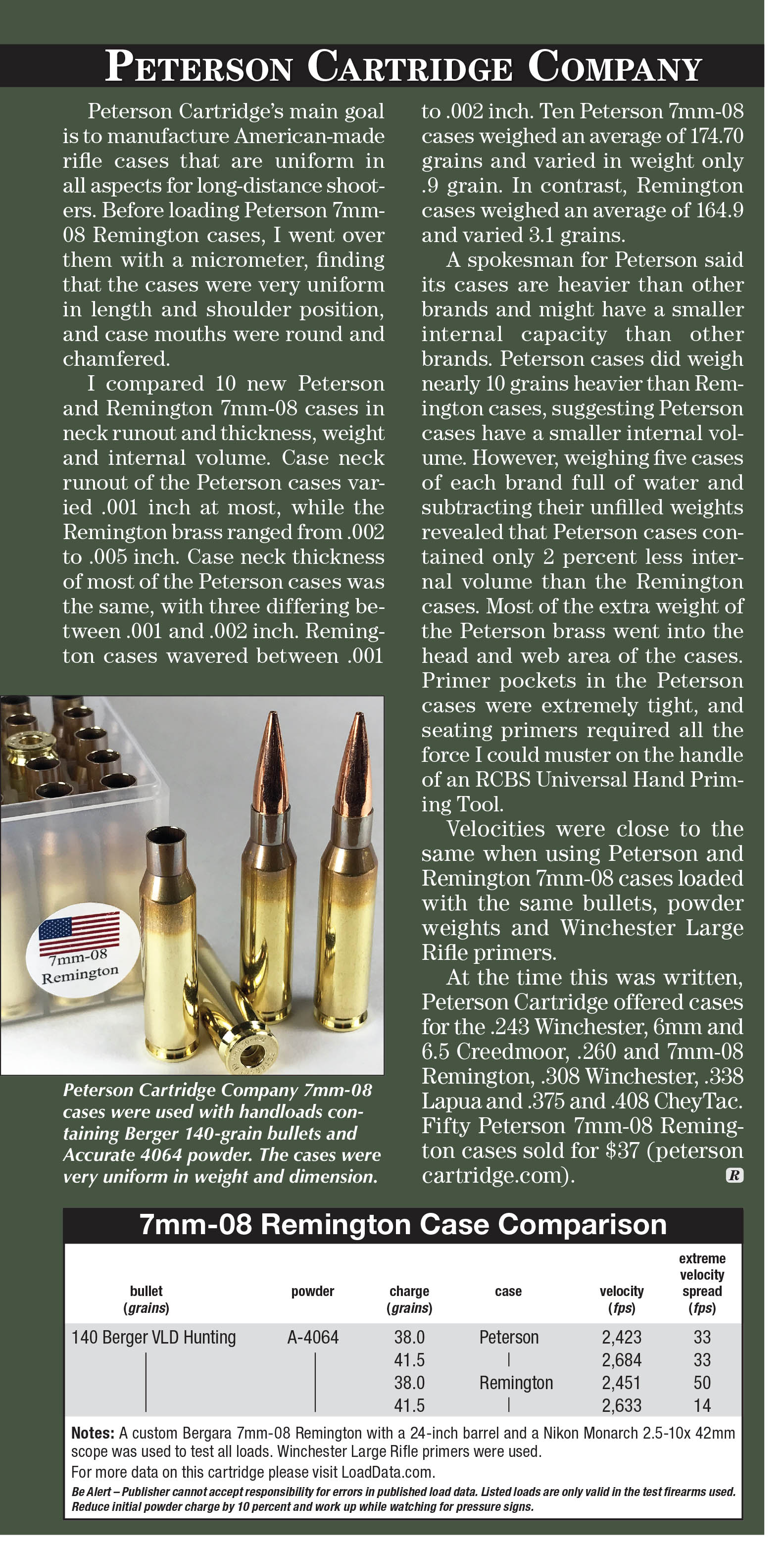

Premier actions come in short and standard lengths. The custom rifle I shot was a Sport Hunter with some personalized features. The rifle was chambered in 7mm-08 Remington on a short action with a 24-inch, lightweight sporter-contour barrel. Its spring-loaded magazine was contained inside a High Tech ADL stock with only an aluminum trigger guard for bottom metal. The person who ordered the rifle no doubt wanted to lighten the rifle a few ounces by foregoing a hinged floorplate.

The recessed bolt face encloses the head of a cartridge case up to the top of the extractor groove. A sliding blade extractor located on the right-side locking lug grips a case to pull it out of the chamber, and a plunger ejector protruding from the left side of the bolt face kicks it out when the case clears the ejection port. Two nonrotating lugs located behind the locking lugs act to seal the raceway against gas escaping in the unlikely event of a ruptured case. The lugs also slide in the receiver raceway to keep the bolt from binding. The right lug and the right locking lug are slotted and glide on a rail in the raceway to further smooth bolt travel.

The High Tech ADL stock is simply efficient. It weighs a light 28 ounces with a .75-inch-thick Pachmayr Decelerator recoil pad. The stock’s comb is about as high and straight as possible, and the 8.75-inch long forearm is pear-shaped in cross section and fits well in the palm of the hand. The stock is made with injection-molded urethane foam covered with up to seven layers of fiberglass and epoxy composite. It is nearly stiff enough to use as a pry bar.

A Nikon Monarch 2.5-10x 42mm scope in steel rings on two-piece steel bases was mounted on the rifle. The whole outfit weighed 7 pounds, 9 ounces.

Bergara states “All custom rifles are capable of producing sub .5 MOA or less [groups] at 100 yards.” That’s a sizable accuracy guarantee. Fulfilling it requires finding factory or handloaded ammunition that shoots that well, agrees with the rifle, and a shooter capable of doing his part.

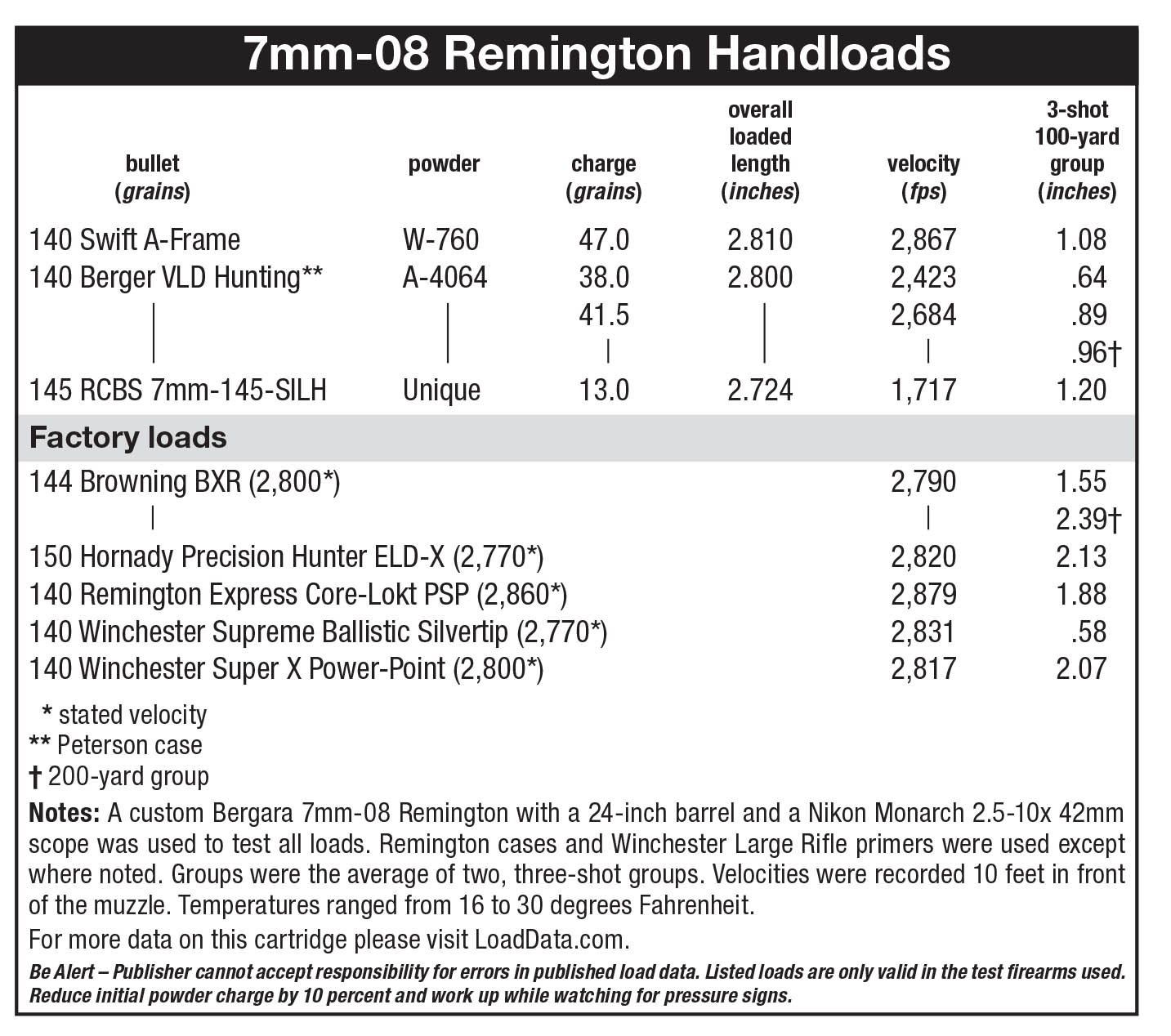

I shot five factory loads and four different 7mm-08 handloads through the rifle supported on a bench. The accompanying results table lists the average size of two, three-shot groups fired at 100 yards. Of the factory loads, Winchester Supreme 140-grain Ballistic Silvertip ammunition came the closest to the Bergara guarantee with three-shot groups of .51 and .66 inch for an average of .58 inch.

My standard practice load for the 7mm-08 consists of bullets cast from an RCBS 7mm-145-SILH mould loaded with 13.0 grains of Unique. The Bergara rifle shot the cast bullets in a 1.00-inch group followed by a second 1.41-inch group. A winter wind blew that morning, and I was more than pleased.

A look at the Bergara’s bore with a Lyman Borecam borescope showed some shallow tool marks perpendicular to the bore here and there. Mostly, though, the surface of the lands and grooves was smooth. Thin streaks of copper fouling covered a good portion of the bore after firing about 80 cartridges. After firing 35 rounds pretty much one after the other, I shot three Berger 140-grain bullets that formed a 1.02-inch group at 100 yards.

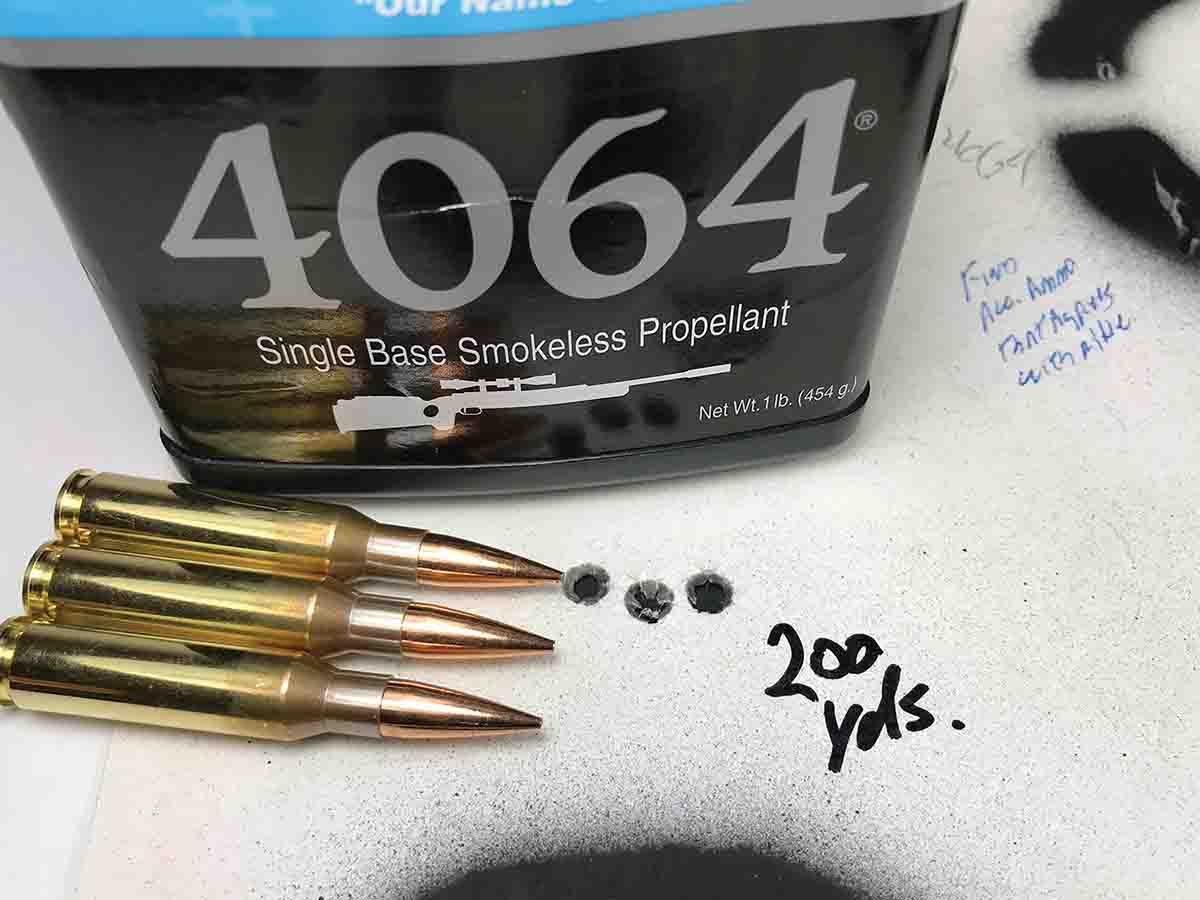

On another cold but calm day, the Bergara rifle was shot at 200 yards with Berger bullets loaded over 41.5 grains of Accurate 4064. The first three bullets formed a .73-inch group, and a second measured 1.19 inches. The .96-inch average meets Bergara’s .5-MOA guarantee.

My trigger-hand fingers were cold from the winter wind, and I held them close to the “hot barrel” to warm them. While my fingers thawed, I eyed the 20-some cartridges doing no good just sitting there in the box. Four at a time, I loaded the cartridges in the magazine and shot them at a steel plate at 300 yards. A fleeting gray cloud surrounded the plate and a steel clang sounded when one bullet after another hit the plate. After firing the last bullet, I had certainly warmed up to the Bergara rifle (bergarausa.com).