Light Gunsmithing

Last Greener GP Actions

column By: Gil Sengel | July, 25

The action was very strong and could be rebarreled for any classic rimmed cartridge. I had one chambered in 219 Zipper. They appeared on the surplus market around 1960.

Sometime prior to World War II, Greener decided to “sporterize” the Police Gun and sell it as a 12-gauge, much like the cheap American farm gun. These were called GP (General Purpose) guns. They sold quite well throughout the world except the U.S., probably due to cost.

After World War II, Greener was sold and split up, with Webley & Scott buying the gunsmithing part of the business in 1965. Besides expensive guns in the process of being finished, Webley & Scott also received a large number of complete GP guns and parts. The GP was considered a “machine made” gun in British parlance, with buckets of parts stored for assembly when orders came in.

Also listed was a 32-inch barreled 12-gauge trap gun made on a blued GP action. The reason this is mentioned is that a bit later Navy Arms showed a GP action with a 32-inch, 12-gauge barrel, no stock, no safety, all in the white. When Dad’s arrived, the polishing of the metal was superb! It looked like it had been prepared for engraving. All others I have seen have been the same.

These takedown GP actions seem to be the best big Martinis on which to build a unique British sporting rifle chambered for any of the old-rimmed cartridges that will fit. The only question is whether no safety is preferable to one that may fail. Greener safety troubles were covered in the last column.

Dad barreled his Martini to 45-90 while friends opted for 33 WCF and 45-70. The best was a 28-inch barreled military-style 50-70. Its owner used a commercial grease in bullet lube grooves and a grease wad under the bullet. This controlled black-powder fouling to the point accuracy of the big bullet was not affected.

Not being a Martini fan, I didn’t order one of the barreled actions right away, but they looked like

The complete gun shown is not a rifle despite its iron sights. It’s a 12-bore ball gun. Ball guns were mainly British-made smooth bores firing lead round balls propelled by lots of black powder. Their purpose was to power through in the thick jungles of India, Ceylon, Indochina and several South Pacific islands.

Building a rifle on the Greener takedown GP is done exactly like the smooth-bore gun. The barrel is first. Threads are 14 per inch, V-type. With a clamp screw, completely loose threads are cut to a firm hand-tight fit. Smoking the front of the receiver showed the barrel on this gun abutted uniformly all the way around. That wasn’t expected. Tightening the clamp screw now locks the barrel solidly yet allows easy takedown for cleaning.

Next, an anchor block needs to be attached to secure the forearm. The one shown is ½ x 1 inch and is located 5 inches ahead of the receiver. Two 8x40 threads per inch (tpi) screws and solder hold it in place. Because of the recoil, I only want to do this once! Note that the front and rear surfaces are angled inward about 10 degrees. This allows (when reinforced with a bit of epoxy) the forearm to slip easily over the block with no looseness, something square blocks never do. The forearm will also slip over a mandatory “cover block” addition

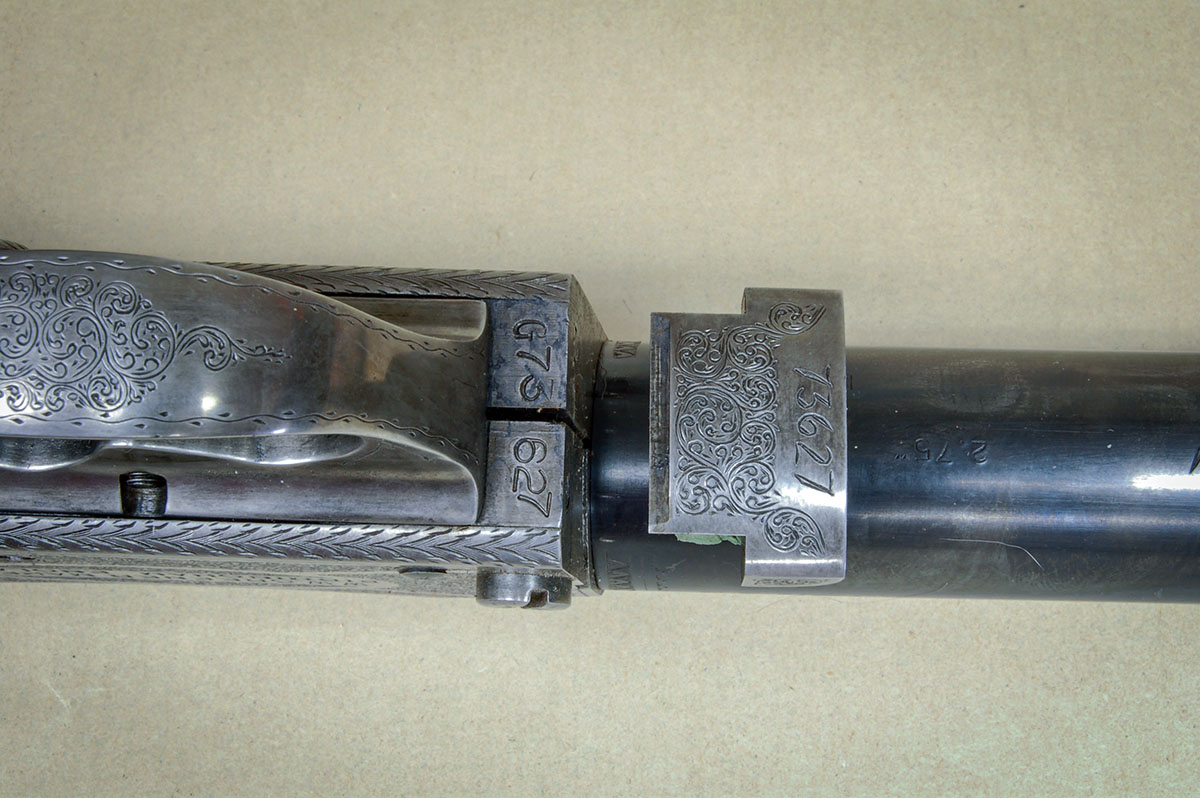

Note that the slot in the receiver ring continues down, out the bottom of the action and that the receiver is machined flat at this point to accommodate the trigger guard. The visible section shows a crudely stamped serial number and mill cutter marks. It looks like a lawnmower part. This will go away by making the cover shown.

Unfortunately, the large 90-degree cut at the rear of the cover block pretty much has to be made by a milling machine. Be certain the thin end is long enough to fit under the front of the trigger guard. There is a slot there, seemingly in anticipation of such a part. The half-round front portion is shaped by filing to no particular form. One screw secures it to the front of the action. Looking something like a forearm iron for a break-open gun, the cover is not out of place and lends a finished look.

Disassembly and reassembly are simple, so they aren’t covered except for the removal of the stubborn split pin holding the breech block in place. Yes, that’s right, what looks like a screw slot is really a cut that splits the pin in half for most of its length. It is removed by driving from the slotted end with the action laid on a 6-inch length of 2x4 lumber. A hole is drilled in it slightly larger than the split pin. Center the pin over the hole and hit the pin with a punch and hammer. All come out hard, and some are harder yet. Hit it again.

Of course, any rifle needs a stock, and the Greener GP is easy. In typical Martini fashion, a huge longitudinal bolt clamps the buttstock to the receiver. It is suggested that a pistol grip be formed to match the lever, allowing the end of the lever to curve under the grip cap area, as shown in the photos. This really looks good. Also, don’t forget to inlet a small piece of steel behind the pistol grip for the end of the lever to fit into. No mechanical latch is necessary. It just needs a bit of friction to hold the lever against the stock.

Greener “sporting” GPs and Navy Arms GPs are found on the internet from time to time. Although the heavy trigger pull and non-reliable safety (or no safety at all) make them unusable as a shotgun for wing shooting, they can be made into rifles.

After all, most big Martinis and Martini Cadets had over four-pound trigger pulls, and none had a safety. Spending a few bucks on the trigger and rebarreling to an old rimmed round yields a unique plinker for Martini fans.