Winchester Model 1885

John Browning's first rifle is still in production.

other By: Brian Pearce | January, 26

The Browning family lived in the small frontier town of Ogden, Utah, where they ran a sporting goods store, sold guns,

One day young John was repairing a single-shot rifle, and the mechanical design was complex and poor. He showed it to his father and commented, which he probably did not mean literally: “I could make a better gun than that myself.” Jonathan knew of his son’s gifts and talents and wisely responded, “I know you could John Moses. And I wish that you’d get at it. I’d like to live to see you do it.”

Young Browning made every excuse he could think of, but ultimately knew he must design and build his own rifle. Work began almost immediately. This was the frontier, however, and the tools in the Browning shop were very limited. Parts were all hand-forged, being heated to a cherry red, then pounded to near form with special hammers and anvils, with their final shapes being performed primarily by chisel, file, foot lathe and drill. According to John Browning, he had many ideas on how to shape a given part, but it was the simplest designs that he chose, as they were easiest to construct for his prototype rifle. This simplicity is what ultimately led to a rugged, strong and reliable design.

At age 73, Jonathan Browning’s health was beginning to fail, but six weeks before his death he had the opportunity to test-fire the patented prototype rifle and see the beginnings of his son’s remarkable success as a prolific gun designer.

John Browning hardly knew what to do with his newly patented rifle but ultimately decided to manufacture it himself, along with the aid of his brothers. With very limited means, by 1880 he constructed a new brick building; then, using mostly equipment (steam engines, etc.) that had been left in the region when the Transcontinental Railroad (or Pacific Railroad) was completed in northern Utah in 1869, he began transforming this oddball equipment into the necessary tooling to build guns. With no manufacturing experience, his “factory” became an interesting menagerie of innovative inventions and nontraditional techniques.

In 1883 a western U.S. salesman for Winchester Repeating Arms, Andrew McAusland, purchased a single-shot rifle that displayed heavy frontier use and was marked “BROWNING BROS. OGDEN, UTAH U.S.A.” It bore the serial number 463 and was chambered for .45-70 Government. He promptly recognized this as a truly great rifle and shipped it to Winchester Vice President and General Manager T.G. Bennett. Upon studying its unique design, Bennett described it as “the best single-shot rifle he had ever seen.” This statement was significant, as he was unusually well educated, having graduated from Yale Sheffield Scientific School with studies in mechanical engineering. With his additional experience as general manager at Winchester, few men were as qualified to understand the significance of such a rifle.

Bennett had never heard of the Browning Brothers but was concerned about the competition. Furthermore, Winchester had been trying to develop its own single-shot rifle that could handle all centerfire cartridges up to the big .50 calibers (and especially the .45-70) but had been largely unsuccessful.

Bennett was clearly taken aback by their extreme youth, not to mention that they had designed, patented and were now manufacturing a rifle of such outstanding quality.

The meeting was pointed: Winchester wanted to buy and Browning wanted to sell, and negotia- tions were quick. For a reported $8,000.00, plus a jobbing grant, Winchester owned exclusive manufacturing rights, but Browning Brothers could finish guns and parts that were in the production process. The total number of guns produced in Ogden is unknown but was probably fewer than 600 units that are now highly sought after by collectors.

During this first meeting with Bennett, Browning described a repeating lever-action rifle that he was working on that was capable of handling large centerfire cartridges. Winchester had developed the Model 1876, but it could not accommodate the .45-70 Government and similar cartridges, while Marlin was building its Model 1881 that could. Bennett expressed great interest in Browning’s new repeater and groomed the relationship for future dealings.

With manufacturing off John’s shoulders, the new repeater lever action was soon completed and patented, with manufacturing rights being sold to Winchester, which became the Model 1886. From this point forward, completely new designs just seemed to flow from Browning’s mind with incredible speed. At his death, he had at least 128 patents that included over 80 separate firearm designs.

The relationship with Winchester lasted 19 years, with Browning designing many rifles, shotguns and even cartridges, which resulted in a flurry of sales that helped Winchester become the largest producer of sporting arms in the U.S. After that relationship was severed, Browning designed guns that were produced by Remington, Savage, Ithaca and others. He developed autoloading shotguns and many notable pistols, including the timeless Colt Model 1911. Ultimately, many of his designs were produced overseas, and he eventually developed many advanced arms for military use. Browning always said his first rifle was the most important; that makes the Browning 1878/Winchester 1885 one of the most significant guns in history.

Winchester immediately tooled up and put the Model 1885 single-shot rifle into production, which enjoyed brisk sales. It was produced in most popular calibers from .22 rimfire through various .50 calibers and was even offered as a 20-gauge shotgun. It was available in many special-order variations, with standard models including Sporting Rifle Low Wall, Sporting Rifle High Wall, Schuetzen Rifle, Deluxe Sporting Rifle and High and Low Wall Muskets. The option list was long and included case-colored frames, fancy grade checkered walnut stocks, a takedown option, set triggers, a variety of sights for hunting to target and barrel contours and lengths, etc. Target competitions were very popular during this period, and the new Winchester had to compete with such outstanding rifles as those offered by Ballard, Sharps, Stevens, Maynard and Remington, and it excelled. I believe Ned Roberts (of .257 Roberts fame) best summed up the Model 1885, stating that it was “the most reliable, strongest, and altogether best single shot rifle ever produced.” Regular production lasted through 1920, with nearly 140,000 units being sold.

I have had the opportunity to own and fire many vintage Model 1885s. When the bore is in good condition and loads carefully chosen (factory ammunition and handloads), they have almost always exhibited excellent accuracy, while function has been flawless. High-condition versions are commanding premiums, often more than the average shooter is willing to spend. However, there are quality reproductions available at a much lower cost. Examples include Browning and Winchester/USRAC/BACO, all of which are manufactured in Japan by Miroku, while the Italian firms Pedersoli and Uberti offer examples that are primarily chambered in vintage calibers.

For the purposes of this article, two Browning Model 1885s were chosen. The history of these guns actually began in 1973 when Browning began importing the B-78 that was something of a modernized 1885 but chambered in high-velocity hunting cartridges that ranged from .22-250 Remington through .45-70. Beginning in 1985, the B-78 was replaced with various Model 1885s that included High and Low Wall versions chambered for traditional cartridges, and modern ones ranging from .22 Hornet through .30-06. They were also chambered for popular straight-walled pistol cartridges, such as the .357 and .44 magnums, .45 Colt and .454 Casull.

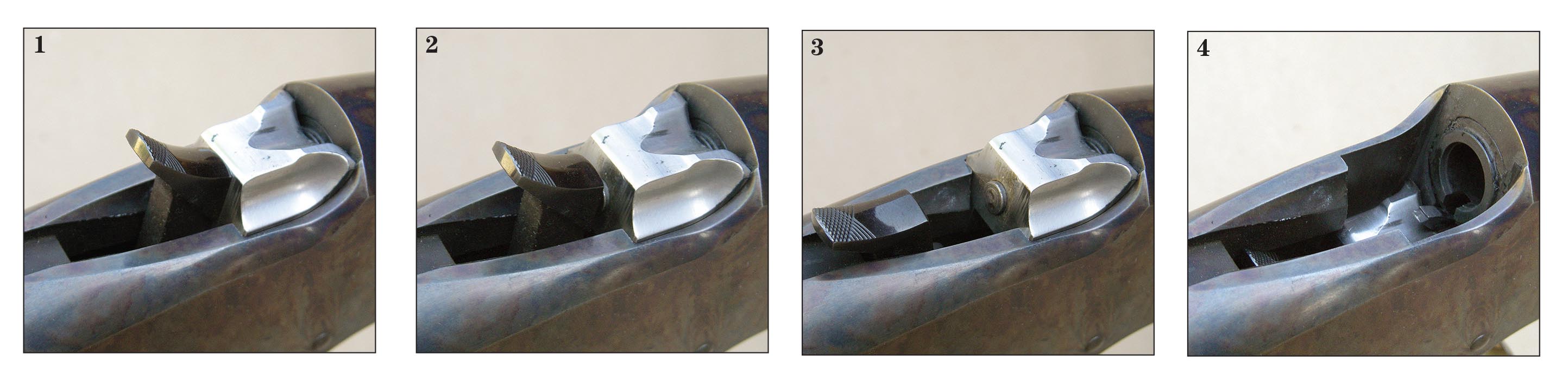

The second feature is an inertia hammer sear. With a round in the chamber, when the lever is lowered along with the falling breechblock, the hammer is automatically cocked. Upon closing the action, the rifle is ready to fire, or the hammer can be lowered to the traditional safety “half-cock” notch that is similar to the function of traditional lever-action rifles. The Browning 1885 as manufactured by Miroku automatically engages the safety. For example, rather than having the option of lowering the hammer to the “firing” position, then pulling it back slightly to engage the safety notch, it automatically engages the safety. Essentially, if the hammer were to slip from under the thumb while it is being lowered, the inertia sear would prevent the rifle from firing.

Beginning in late 1999, the Model 1885 was changed from the Browning name back to its sister company Winchester, but it was still manufactured by Miroku in Japan and is the same rifle. However, it has been offered in various Winchester Short Magnum cartridges, rimfires and additional cartridges as demand warrants.

The two Browning 1885s used here were a Low Wall Traditional Hunter .45 Colt and a High Wall .45-70. For clarification, Low Wall rifles feature a lower profile receiver “wall” that reduces weight and gives easier access to the barrel breech. They are generally not as strong as High Wall actions that offer greater support to the falling breechblock. These rifles are constructed of modern steels, with the receiver consisting of heat-treated 1045 steel with a Rockwell hardness of 38, while the breech bolt is hardened to 45, making them suitable for modern high-pressure cartridges. The barrels are button-broached, straight and beautifully finished.

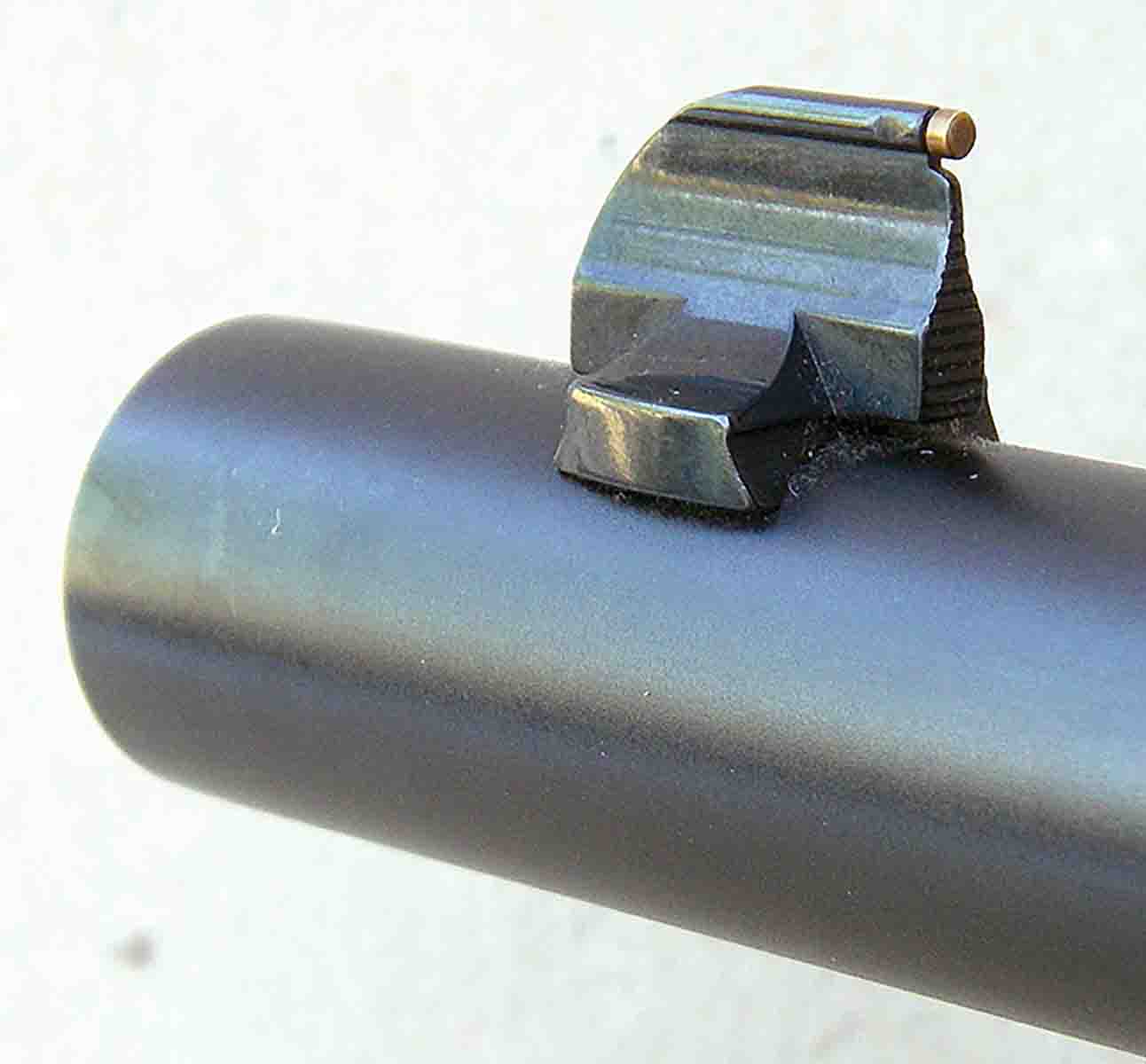

The Traditional Hunter features a case-colored receiver and tang-mounted Marbles aperture, folding rear sight that is fully adjustable for windage and elevation. It also features a semi-buckhorn rear sight and gold bead front. The half-round, half-octagonal barrel is 24 inches. The French walnut stock is well figured, and the buttstock features a traditional crescent steel buttplate.

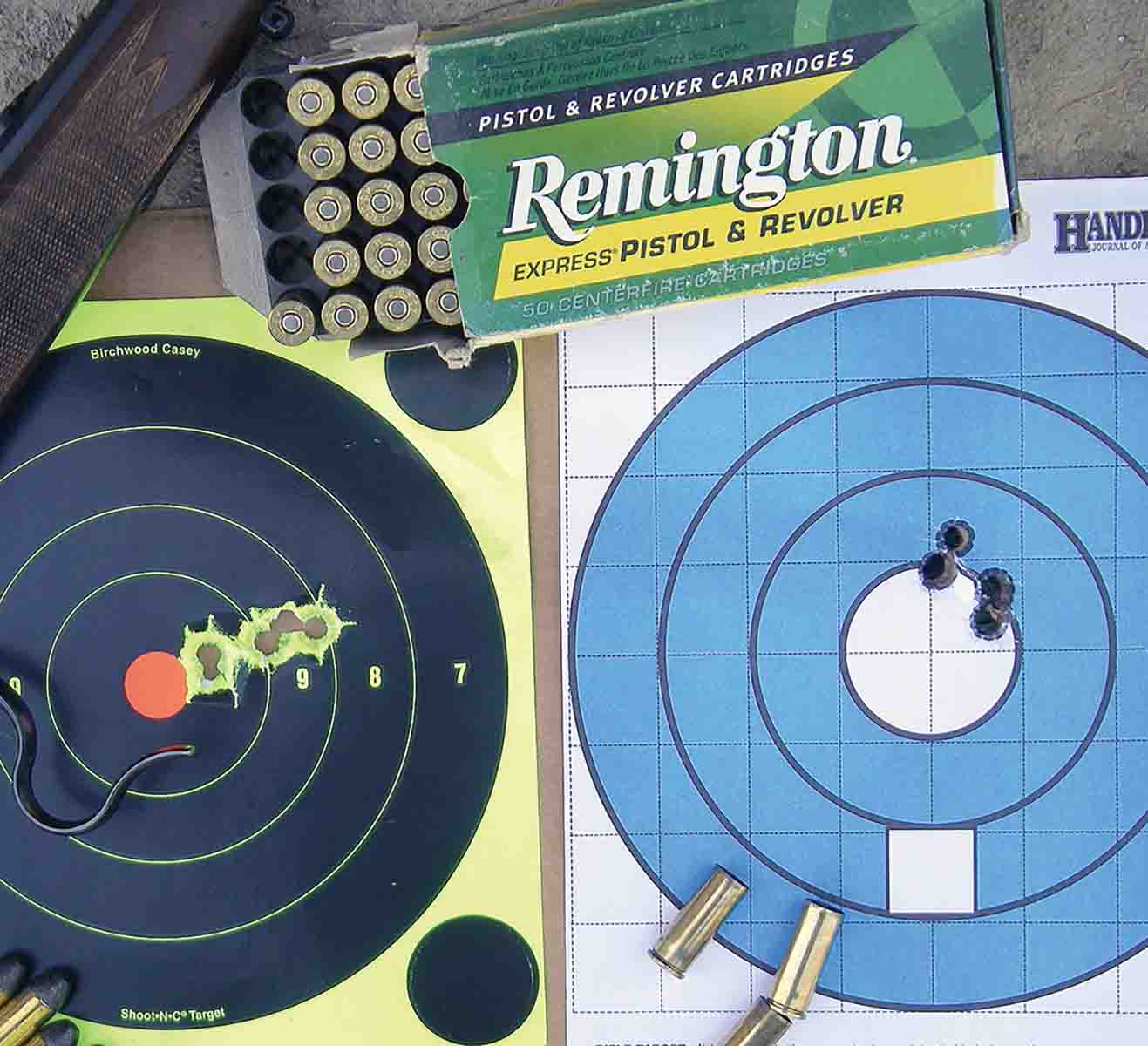

With the aid of sandbag rests, at 50 yards Remington’s 255-grain swaged lead load grouped four shots into 1.10 to 1.70 inches. Handloads were also tried that consisted of 260-grain cast bullets from Lyman mould 454190 pushed with 8.2 grains of Alliant Power Pistol, which consistently stayed under one inch. At 100 yards groups only opened to 1.05 to 1.30 inches. With some additional experimenting, groups are expected to drop to sub-MOA.

The Model 1885 High Wall .45-70 produced even better accuracy. This rifle had open sights (semi-buckhorn rear, blade front) but is also drilled and tapped for scope mounting, with a Leupold VX-1 4-12x 40mm scope installed for testing. Three factory loads from Buffalo Bore, Garrett Cartridges of Texas and Remington were tried. The Buffalo Bore load, containing a 430-grain Hard Cast bullet at 1,925 fps, managed to place four shots into .70 inch. The Garrett 420-grain cast Hammerhead bullet at 1,650 fps stayed within one inch for three consecutive four-shot groups. The Remington 405-grain JSP bullet at 1,330 fps produced groups that measured between .90 and 1.65 inches. Some of the best groups from carefully assembled handloads placed three shots into just over .5 inch.

The Model 1885 is a timeless sporting rifle and is clearly one of the most significant firearm developments in modern history.

.jpg)

.jpg)