Varmint Cartridge Propellants

Our powder expert picks a quintuplet of favorites.

other By: R.H. Vandenburg, Jr. | January, 26

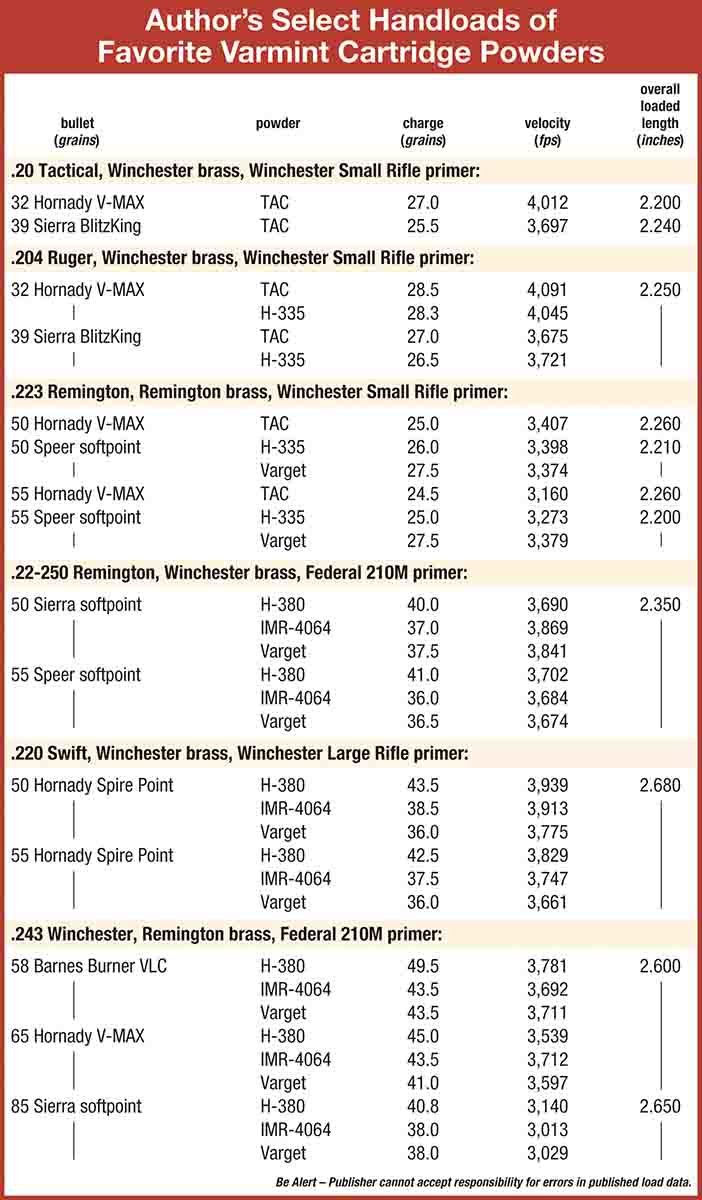

I admit to not being a particular fan of cartridges having bullet diameters smaller than .224 inch. That is not to say I don’t have experience with them or haven’t taken a fair number of varmints with them. I just prefer the .22s to anything smaller. That said, I include here a couple of .20-caliber cartridges: .20 Tactical and .204 Ruger.

My most used .22-caliber cartridges for varminting include the .223 Remington, .22-250 Remington and .220 Swift. I’ve used a number of others on varmints and/or paper, including the .22 Hornet, .218 Bee and .222 Remington of the older cartridges and the .223 Winchester Super Short Magnum among the newer.

The last cartridge on my most-used list is the .243 Winchester. There have been a fair number of lightweight bullets, from 58 to 85 grains, sent downrange in pursuit of woodchucks, marmots, prairie dogs, ground squirrels and jackrabbits, not to mention the odd crow here and there.

Turning to my favorite varmint powders is another matter. We begin with ball (spherical) powders, as the typical varmint cartridge’s modest case capacity lends itself to their greater density and energy. The first of those I’ve come to regard as my favorite is TAC, from Western Powders’ Ramshot line. TAC is at its best, it seems, in the .20-caliber cartridges and the .223 Remington, at least among varmint cartridges. It also shines in the .222 Remington, of course, and in several of the .17-caliber rounds. When introduced, TAC was especially recommended in the .308 Winchester.

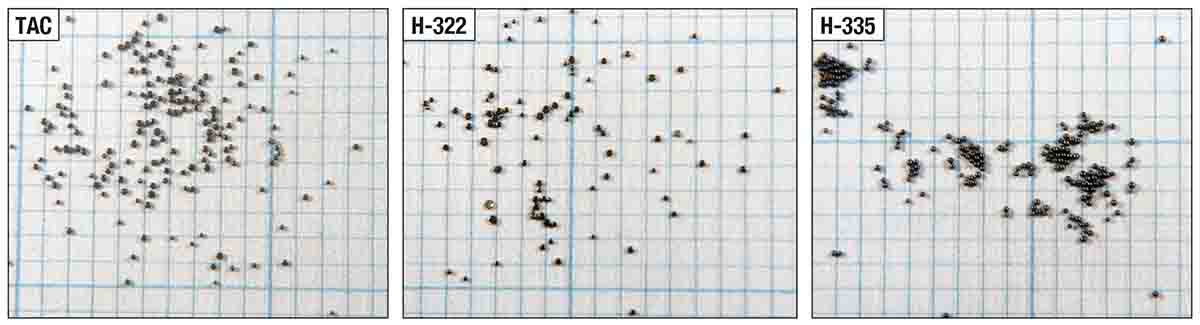

With many more powders to choose from now, I’ve narrowed use of TAC to that of a varmint powder for the most part. The powder itself is a double-base, ball powder manufactured in Belgium and imported by Western Powders in Montana. It is, I’m told, by far Western’s most popular powder, not only for handloaders but also as an OEM (non-canister) powder sold to ammunition manufacturers. Individual grains are quite small; bulk density is an impressive .985g/cc. Metering is flawless, and the powder is quite clean-burning. Though a spherical powder, almost all TAC data pairs the powder with standard strength primers. With the traditional small case capacity of varmint cartridges, I’ve found no reason to question this approach. With larger-capacity cases, I would opt for a magnum spark plug. There is little not to like.

A second favorite is Hodgdon H-335. Another spherical, double-based powder, H-335 is manufactured in the General Dynamics facility at St. Marks, Florida, for Hodgdon. It was originally developed by Olin Corporation’s Winchester division for the 5.56 military cartridge, the .223 Remington to the rest of us. Introduction as a canister powder occurred around 1963. H-335 was promoted as ideal in the .223 and .222 Remington cartridges, and acceptance has grown over the years to include many more. Unlike TAC, however, magnum strength primers serve us better when using H-335, as it is more heavily coated than many powders. Several reloading manuals have highlighted H-335 as the most accurate powder in such cartridges as the .223 Remington and 7.62x39, among others.

H-335’s burning rate, according to Hodgdon’s 2013 Annual Manual, falls between IMR-3031, Vihtavuori N133 and Hodgdon’s Benchmark on the faster side and Accurate 2230, IMR-8208 XBR and Ramshot TAC on the slower. These precise placements can fluctuate with cartridge and bullet weight, but it gives us a broad picture of the powder’s usefulness. Metering is excellent. I’ve seen H-335’s bulk density stated as greater than water at 1.01g/cc, but suffice to say, it is dense and performs accordingly. It also has been stated by some that H-335 leaves more residue than more modern spherical powders. Perhaps, but it is nothing that should cause alarm, even in varmint hunting situations, and nothing that a good cleaning regimen won’t cure.

While H-335 has been used in everything from the .17 Remington to the .458 Winchester Magnum, it is included here because of its excellent performance in the .20 calibers and the .223 Remington.

A final ball powder on my list is Hodgdon’s H-380. As with so many other Hodgdon powders that have been around for a long time, it began its civilian life as a military surplus powder, having been developed by the Western (Olin) Cartridge Company for government use in the .30-06 with the M2 (150-grain) bullet. Its factory name was WC-852. When Hodgdon’s surplus supplies ran low, the company approached Olin for a new replacement. New production H-380 does not contain the flash suppressant required by the original military WC-852.

H-380’s nitroglycerin content is 10 percent. Its bulk density is listed as .940g/cc. It is the slowest of the ball powders selected, having a burning rate between IMR-4320 and -4350. Hodgdon’s 2013 Annual Manual lists H-380 as falling between BL-C(2), CFE 223 and LEVERevolution on the faster side and IMR-4007 SSC, Ramshot Big Game and Vihtavuori N540 on the slower. Older reloaders will recall H-380 got its name from the fact that, during early experiments, Bruce Hodgdon discovered that 38.0 grains of it performed exceptionally well in his .22-250 with 55-grain bullets. Today that load is still a fine performer but is considered a starting load in Hodgdon’s data, with 41.0 grains listed as maximum for that bullet weight.

As with H-335, H-380 data was developed with standard strength primers; Speer data calls for magnum primers when using H-380. It is fair to say that among the varmint cartridges selected for this article, H-380’s usefulness is limited to the .22-250 Remington, .220 Swift and light bullets in the .243 Winchester. Indeed, modern published data clearly suggests newer powders have passed it by in the .22-250. It still produces top velocity in the .220 Swift and with some bullets in the .243 Winchester. No matter, for long-range varmint shooting, within reason, accuracy is more important than velocity, and few can complain H-380 ever let anyone down on that score.

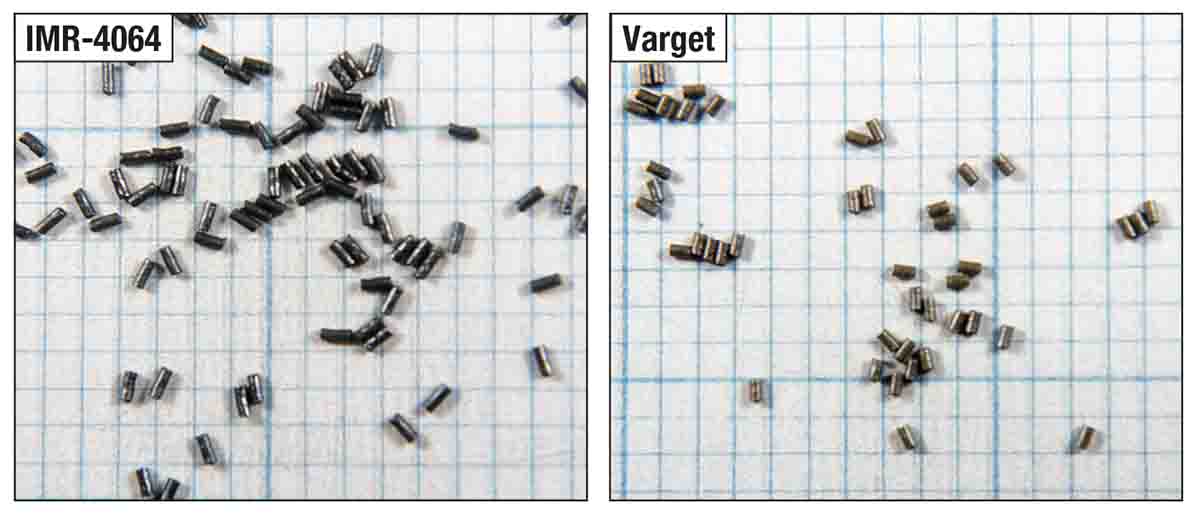

Turning attention to extruded powders, their lower bulk density serves to ensure optimum loading density as case capacity increases. As such, these powders are best, among our varmint cartridges, in the .22-250 Remington, .220 Swift and .243 Winchester. Extruded powders do not meter as well through powder measures as do the denser spherical powders but frequently are cleaner-burning and often noted for their contributions to accuracy.

My first selection in this category is IMR-4064, first introduced by DuPont in 1935 to replace the discontinued IMR-15½. The powder is single-base, deriving its energy from its cellulose base, extruded, with a single perforation. Granule lengths are nominally .083 inch; their diameter, .032 inch. The perforation diameter is .006 inch, leaving a web of .013 inch. Bulk density is said to be .910g/cc.

In Hodgdon’s 2013 Annual Manual, IMR-4064 falls between IMR-4895, Vihtavuori N135 and Accurate 2495 on the faster side and Accurate 2520, Reloder 15 and Vihtavuori N140 on the slower.

IMR-4064 is excellent in the .22-250 Remington over several bullet weights from 35 to 55 grains. In the .220 Swift it also excels in the same range of bullet weights, often producing near-top velocities along with fine accuracy. For many years, in the .243 Winchester for hunting weight bullets, my powder of choice was IMR-4350. For lighter-weight varmint bullets from 58 to 85 grains, it was, and is, IMR-4064. That IMR-4064 is among the most useful powders in cartridges ranging from the .17 Remington to the .458 Winchester Magnum only adds to its mystique.

My final favorite varmint powder is Hodgdon’s Varget. Much of what has been said regarding IMR-4064 can also be said of Varget, although Varget seems to enjoy more use in the .223 Remington. When Varget was introduced in 1996, it was often thought of as a short-cut 4064 – not to imply any interchangeability of load data, but rather as a point of reference. Actually most burn rate charts list Varget as slightly slower burning than IMR-4064, although I’ve run several comparative tests that showed Varget generating higher velocities and pressures than IMR-4064 using the same powder charge, bullet and primer in the same cartridge and gun. Such things can vary and, in truth, there is little to choose between them, which is why both made my list.

Varget was the first of the Hodgdon powders to be marketed under its Extreme Powder label, although not the first to be manufactured using the proprietary process. These powders are noted for their clean-burning nature and lack of sensitivity to changes in temperature. They are manufactured in Australia at the former ADI facility and imported by Hodgdon. Among Extreme Powder characteristics are multiple perforations to control burning under adverse conditions and a minimum of graphite to reduce static electricity and facilitate flow through loading machines and powder measures.

Varget’s measurements are, nominally, a length of .060 inch and a diameter of .033 inch. Bulk density is .925g/cc. Its improved density over IMR-4064 allows Varget to find favor in the .223 Remington, although just about every maximum load in the cartridge is compressed. Still, performance is very good. In the .22-250 Remington, with its larger boiler room, Varget need not be compressed, but one still gets a case that is satisfyingly full and accuracy is typically as good as the gun and other components will permit. Much the same can be said for the .220 Swift, where accuracy with Varget has always been top notch.

In the .243 Winchester with light varmint bullets in the 58- to 85-grain range, Varget, like IMR-4064, has produced exceptional results.

Well, these are my favorite powders for varmint cartridges. Had I been asked for my favorites a decade ago, my answers might have been slightly different. Ten years hence I have no doubt I’ll change my mind again as my experience, especially with some of the newer powders, grows. If you have a favorite I’ve ignored, that’s all right too. Different guns, components and conditions can justifiably vary opinions.