Mauser's Claw: Myth or Magic?

Controlled Feed and a Mighty Tug on Stubborn Cases

other By: Wayne van Zwoll | July, 24

The Model 70 and the Mauser licked cartridges and spewed hulls as fast as we could cycle their bolts – bolts developed 130 years ago.

Many hunters recognize Peter Paul Mauser’s non-rotating extractor as a defining feature of his 1898 bolt action. Actually, that long extractor spring, held to the bolt body by a collar, first appeared on his Model of 1892. Lifted by the magazine’s follower into an open breech, the rim of the top cartridge in the stack rose into the claw

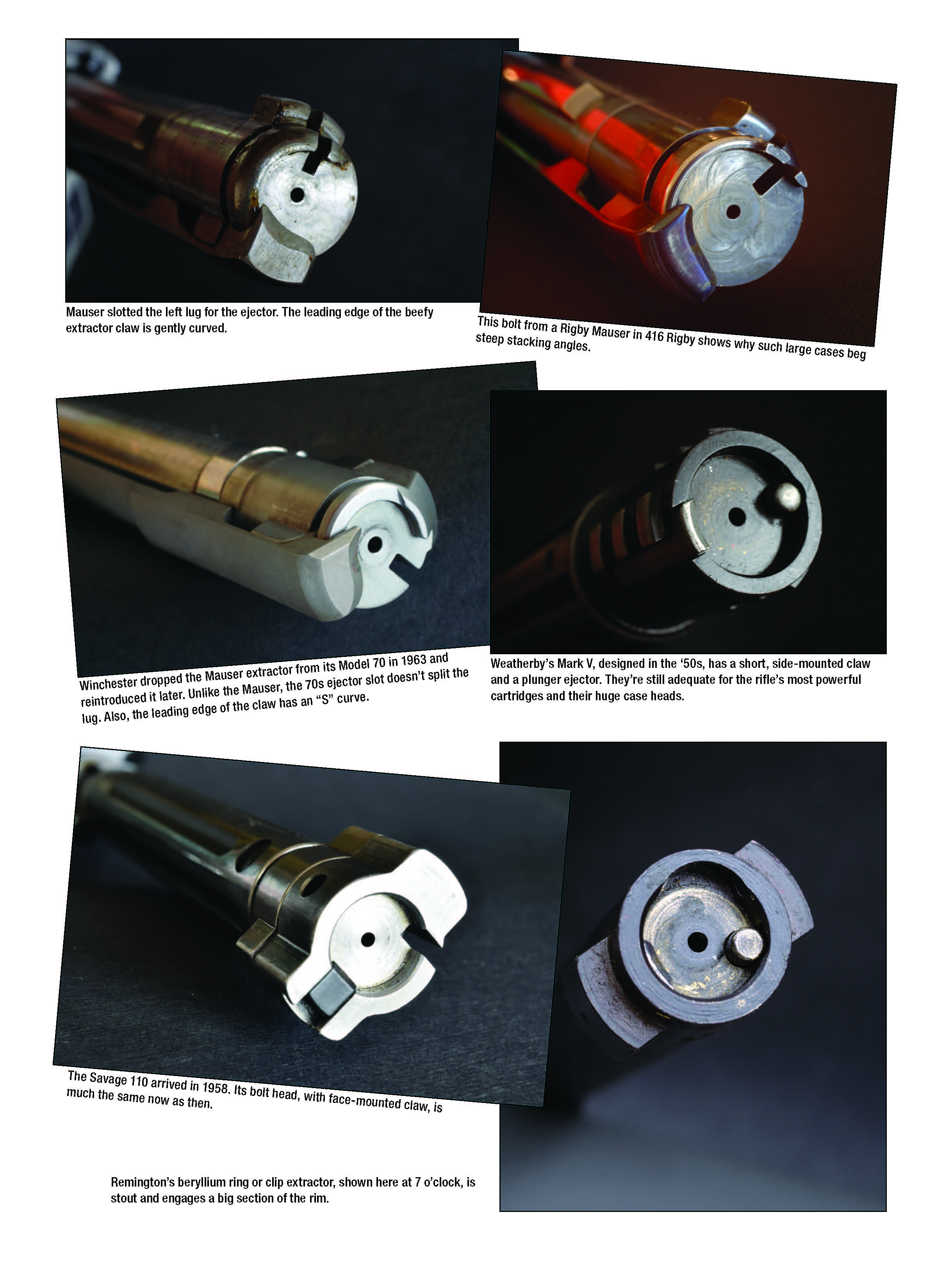

Bracketing the ejector groove on a 98 bolt face are two cartridge support lugs. The lower of these is angled to guide each round as the magazine spring pushes it up. This lug matters because the Mauser’s staggered cartridge stack is not funneled at the top into a single column that feeds into the action’s center. Positioned on the bolt face, the case head is supported by both lugs. The angle and bearing surface of the lower lug determine how easily a cartridge crosses the bolt face, yields to the extractor and stays centered as the bolt slides into battery.

The bolt rifle that vaulted Paul Mauser to international fame didn’t emerge until he was 60. But his work in firearms design predated the Franco-Prussian War of 1870. The Dreyse needle gun then served Germany’s infantry. Its turn-bolt lock-up had caught the eye of Samuel Norris, an American agent for E. Remington & Sons. At his urging, Paul and his older brother, Wilhelm, converted the French Chassepot needle gun to feed metallic cartridges. But when the French demurred, Norris pulled support from the project. (Then he filed for a patent stateside. In 1868, this rifle became the first patented Mauser.)

In 1889, Fabrique Nationale d’Armes de Guerre (FN) in Liege tooled up to produce a Mauser rifle for Belgium’s government. The smokeless Model of 1889 confirmed Paul as Europe’s premier firearms designer. Its one-piece bolt had twin front lugs. The magazine could be loaded by a stripper clip. Still, the 1889 (and 1890 Turkish and 1891 Argentine Mausers, also for the 7.65x53 Mauser cartridge) had flaws. The small extractor and its spring could fail; the rifle could be fired with the bolt out of battery.

Paul corrected these faults in the Mauser of 1892. Soon after its debut, he added a flush magazine with a staggered column and a better safety. The 1893 “Spanish” Mauser in 7x57 was adopted by armies worldwide. Sweden’s 1894 and 1896 versions were barreled for that country’s 6.5x55 cartridge.

The Mauser of 1898 cocked on opening and had generous gas ports, plus a third lug that engaged a slot in the bridge. Germany’s army adopted it in 7.9x57 on April 5 of that year. The Gewehr 98 saw early action in the Boxer Rebellion of 1898. Exported to many nations, it was produced in many more. France, Great Britain, Russia and the U.S. designed their own rifles. However, none surpassed this Mauser in function or accuracy.

Peter Paul Mauser died May 29, 1914, just months before his rifle left to serve in the Great War.

Bolts on the first U.S. infantry rifles in 30-06, the 1903 Springfield and 1917 Enfield, also wore long, non-rotating extractors.

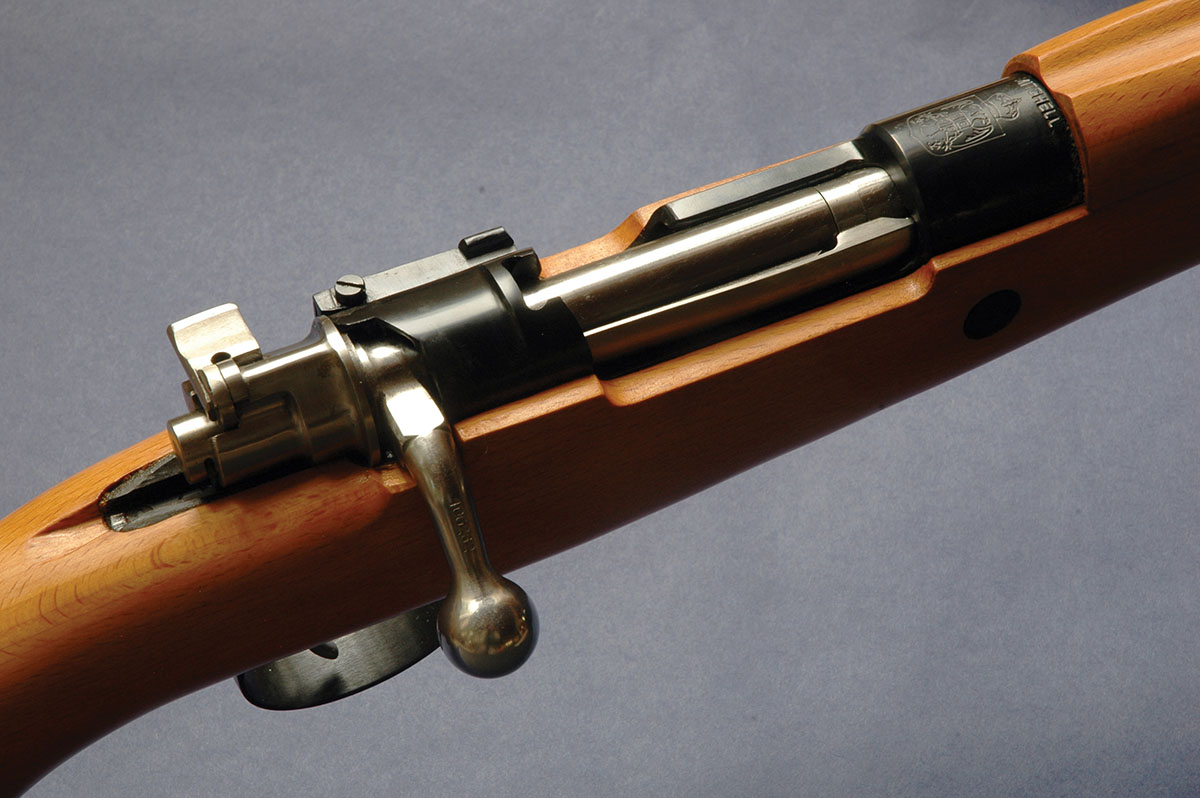

In 1925, Winchester announced its Model 54 rifle and flat-shooting 270 Winchester cartridge. The 54 had a Mauser-style extractor that 12 years later appeared on its successor, the Model 70. The 70 also borrowed from the Mauser’s blade ejector but offset it, leaving the left lug intact. Hunters snapped up this rifle. It had a fetching profile, an excellent trigger. It handled well. In the 1940s, it got a three-position safety and a scope-friendly bolt handle. The Model 70 sold in a wide range of chamberings from 22 Hornet to 375 H&H.

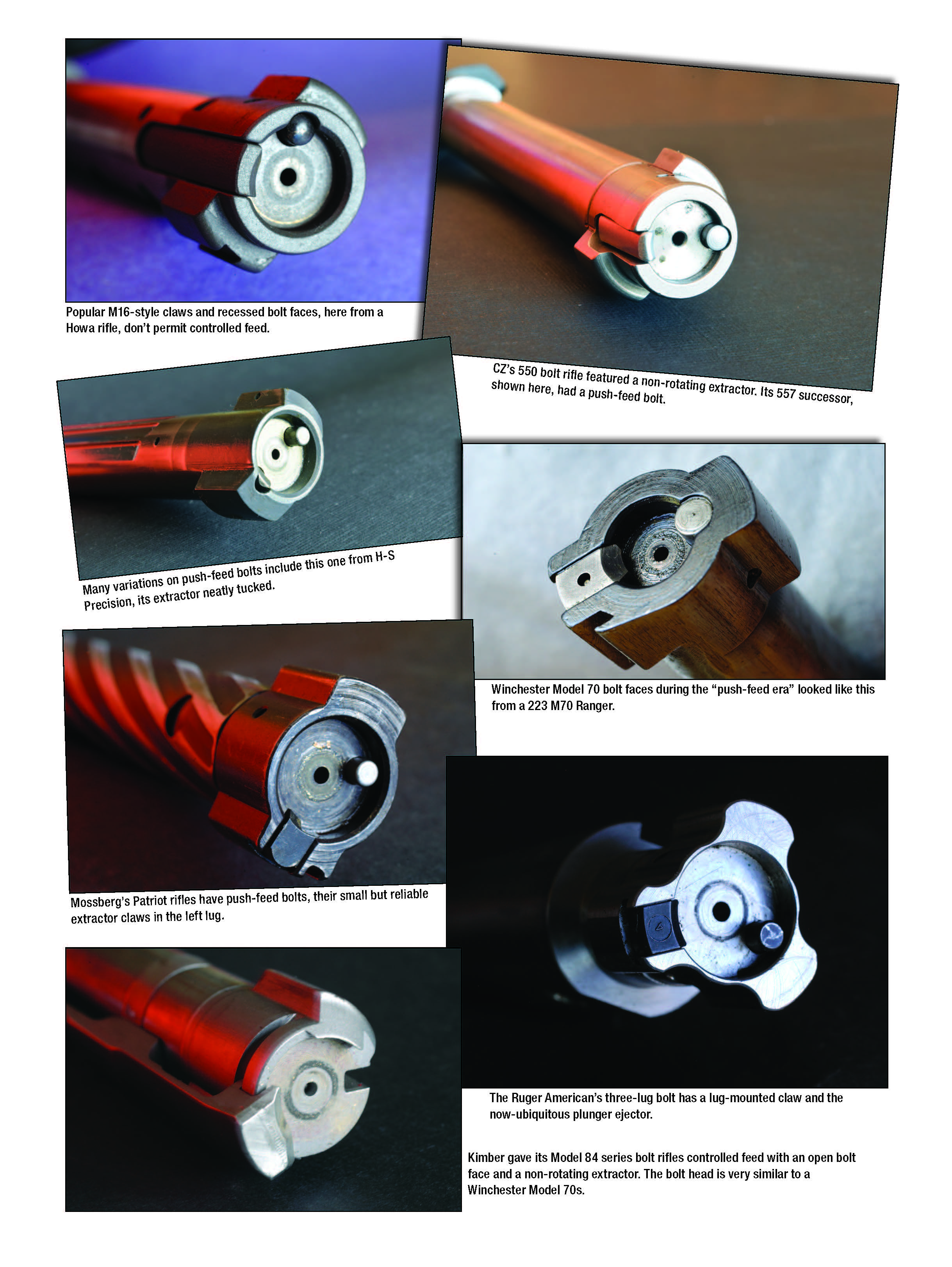

Cost-cutting in Model 70 production late in 1963 drew howls of despair from the faithful. Chief among evils visited upon “the Rifleman’s Rifle” was a push-feed bolt with a small hook extractor pinned in place. Glaringly absent was Mauser’s strong bolt-side spring and, with it, controlled-round feed. Remington had just introduced its Model 700 rifle and 7mm Magnum cartridge. It welcomed the disenchanted from Winchester’s ranks. Oddly enough, the 700 was also a push-feed rifle, like its 721/722 parents. Instead of a face-mounted extractor hook, Remington paired the plunger ejector with its proven beryllium ring or clip extractor, all but hidden in the bolt face rim. When locked into battery, that rim gave the 700 “three rings of steel” about the case head, a feature that contributed to accuracy but was practical only on push-feed rifles. The company sold it skillfully, puffing its belted 7mm as an ideal big-game cartridge, with the reach of a 30 magnum and the recoil of a 30-06.

During my 50-year dalliance with Remington’s Model 700, shooters have replaced its beryllium clip with M16- and Sako-style claws on the side of the bolt nose. Functional and more visible, they offer no real advantage. Cartridges are still push-fed. The clip actually contacts more of the case rim than do most face-mounted hooks! It’s stout too, even with hot handloads, I’ve not had a factory-installed Remington extractor fail.

Still, as accountants savaged Winchester’s flagship rifle, I pined for Mauser’s non-rotating claw. “It’s not cheap to make,” explained an engineer when in the late 1970s, I visited the New Haven factory and pressed him on the decision to abandon controlled feed. “Each long extractor costs us $16. But,” he whispered furtively, “we’re gonna reintroduce it.” So, Winchester did, in 1980. Limited at first to a few variations of the rifle, Mauser’s extractor is now standard on all Model 70s.

The appeal of that bolt-side spring wasn’t lost on Ruger, when in 1968, it unveiled its Model 77 rifle. But appearances were deceiving. That bolt was really of push-feed design. Ruger later revamped the 77 to give hunters the controlled feed they craved. All current 77 Hawkeyes have it.

Commercial Mauser 1898 actions have appeared on Whitworth, Mark X, Browning High Power and other rifles. CZ’s 550 borrowed the Mauser extractor, as did Montana Rifles for its Model 70 clone. Dakota Arms (now Parkwest Arms) patterned its lovely Model 76 after Winchester’s pre-war 70.

Among the most elegant rifles to employ the ‘98 Mauser action have come from Rigby, as its roots predate metallic cartridges. Born in 1758, the first John Rigby opened a shop in Dublin, Ireland. Two years after his eldest son, William, joined him in 1816, John died. The younger son, John Jason, entered the business. It became William and John Rigby, 24 Suffolk St., Dublin. In 1865, it opened an office as John Rigby & Co. at 72 James St. in London, England. The first Rigby “rising bite” double rifle appeared in 1879. It was hand-fitted and expensive. Between 1879 and 1932, Rigby would build only about 1,000.

In 1887, as smokeless powder came on stage, the third John Rigby closed Rigby’s Dublin office and sealed an exclusive 12-year license with Waffenfabrik Mauser, A.G. in Germany to peddle rifles with the new ‘98 Mauser action in the U.K. and its colonies. As that concord drew to a close, prospects for its renewal must have seemed dim. Europe was restive well before an assassination plunged it into war. But both companies had profited from their long-distance partnership and in 1908, Rigby announced a potent, flat-shooting cartridge ideal for a Magnum Mauser action. The 350 Magnum’s 225-grain bullets rocketed downrange at more than 2,600 fps.

The first rifle chambered in 416 Rigby shipped in 1912, as Rigby opened its shop at 43 Sackville St., London. With 410-grain bullets at 2,370 fps, the 416 hurled 5,100 foot-pounds of punch and ranked high on John “Pondoro” Taylor’s list of frothy medium-bores. He wrote of the Rigby Mauser: “I’ve never handled any magazine rifle [except perhaps] the .500-bore Jeffery-Mauser, [whose bolt] was quite so smooth…”

By the time the 416 emerged, with the 505 Gibbs, 9.3x62 and 375 H&H, the safari market was edging away from double rifles to less costly bolt-actions. The 500 Jeffery arrived four years after John Rigby’s death in 1916 and snuffed the development of a 33/416 that would drive 250-grain bullets to 3,000 fps. Revisited by Finland and the U.S. in the 1980s, that idea would become the 338 Lapua.

In 1951, the last of the Rigby family owners, Theo Rigby, died. In 1968, David Marks bought John Rigby & Co. and engaged J. Roberts & Son, established in the ‘50s, to produce its firearms. Paul Roberts acquired the Rigby brand in 1984. In 1997, Neil Gibson bought the company then moved it to California. A Dallas-based investor group snared John Rigby & Co. in 2010 and sent it back to London. Paul Roberts returned to manage it. Three years later, Rigby went to the L&O Group, which came to own Blaser, Sauer and Mauser. Retiring, Paul chose Marc Newton as his successor at Rigby. In 2014, the company moved from London’s high-rent district to its current headquarters at Pensbury Place where, Marc says, “we have a crack team of gunmakers who enjoy making best-quality rifles.”

The actions for current Rigby magazine rifles come from Mauser’s factory in Isny, Germany.

While the ‘98 Mauser’s magazine gets less public adoration than its extractor, the box, spring and follower were surely as difficult to engineer. Staggering cartridge columns to cram the most ammunition into the waists of slender rifles posed challenges not immediately obvious. Mauser and others had the idea well before they figured out how to execute it.

Contemporary rifle-maker D’Arcy Echols openly marvels at Mauser’s work. “Each magazine was made for a specific cartridge,” he emphasized. “These days detachable boxes for push-feed rifles can be made for families of cartridges, so the 243, 260 and 308 fit one box, the 25-06, 270 and 30-06 another. In a controlled-feed action, the follower must present the cartridge precisely. Each cartridge needs support until the extractor grabs it – from the box on one side and from the next cartridge or follower underneath and on the other side. Paul concluded the best stacking angle was 30 degrees. Viewed from the back end, the primers of three cartridges touching each other would thus form the points of an equilateral triangle.”

Math translates that simple image into a steel box. “To calculate rear box width for the .375 H&H Magnum,” Echols said, “multiply the cosine of 30 degrees (.866) by the case head or belt diameter, then add head (belt) diameter to that product.” So .866 x .532 = .460 + .532 = .992. That’s the rear box width. But cartridges taper. To support them, a magazine must also taper. The same formula applies to box width up front at the point of the shoulder – or on a case without a neck, just behind the crimp. A box designed for one cartridge will excel for others only if they share front and rear diameters and the span between them. The cartridge length should be nearly the same.

Paul Mauser also considered the friction imposed by the press of cartridges against the sides of the box between the case head and the point of shoulder. “For rimless cases without belts,” D’Arcy explains, “he relieved the box sides from about .300 forward of the extractor groove to .100 behind the shoulder. A case belt eliminated the need for ribs or other devices to deliver that gap.” On pre-64 Winchester 70s, he noted, three ribs add space for rimless rounds like the 270. “Boxes for belted magnums have one rib, up front.”

Some magnum actions aren’t wide enough for “equilateral triangle” cartridge stacks. Cartridges like the 505 Gibbs, with its .635 base, even the 416 Rigby, with its .589 base, may require steeper stack angles. As long as box walls mirror cartridge taper, pulling cartridges in a tad toward the stack’s center won’t impair cycling. Arguably, it might even improve feeding, as it brings bullet tips nearer the bore axis.

Of course, Paul tapered magazine followers. He also sloped them to keep cartridges level. The width of a follower’s lower shelf is cartridge-specific; a 61‑degree step joins upper and lower shelves.

Original Mausers have generous side clearance for the follower, and spring slots to let it shimmy a bit as cartridges strip. “I cut my first slots for a tight fit,” recalled Echols, “assuming Mauser’s crew was just slopping, making them .180 too wide at the rear. I was wrong! If that spring can’t shuffle, it twists and the follower tips. A follower should have about .060 side-play for the same reason.” Generous clearance fore and aft matters as well. But a follower with too much wiggle can bang the front of the box in recoil; a follower cut too short will dive in front.

Conventional wisdom has it that a rifle for dangerous game must have a Mauser claw, to prevent jams from short-cycling or to haul heavy brass from sooty chambers in tropical heat that hikes pressures. Stripping a cartridge, a push-feed action pops it free into the breech, where it can bounce off the left-side race and dance about until the bolt rattles it home. You may not feel it against the bolt face until lock-up. That can be unnerving and pull your eye from the animal to the bolt. If you must stop an angry beast that suddenly blocks your view of Africa, an able extractor is your friend. I like the feel of a cartridge sliding up the bolt face. It’s an assurance the chamber won’t be empty.

“Time and again have I slammed that bolt back and forth when shooting rapidly,” declared John Taylor in 1948, “yet never once did it show the slightest tendency to jam.” For three decades of hunting Africa’s big game, Taylor had relied on a Rigby on an 1898 Mauser action. He concluded: “[There’s no] better or more reliable magazine rifle…”

Many hunters agree. Indeed, Paul Mauser’s nineteenth century ideas for cycling cartridges through turn-bolt actions can seem, to all but accountants, timeless!